High temperature resistant anti-corrosion anti-nuclear radiation nano-modified organosilicon coating and its preparation and application

A nuclear radiation-resistant and anti-corrosion technology, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the oxidation of substrate materials under the coating, poor nuclear radiation resistance and corrosion resistance, salt spray corrosion, etc. problems, to achieve the effect of improving compactness, simple preparation process, and good high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

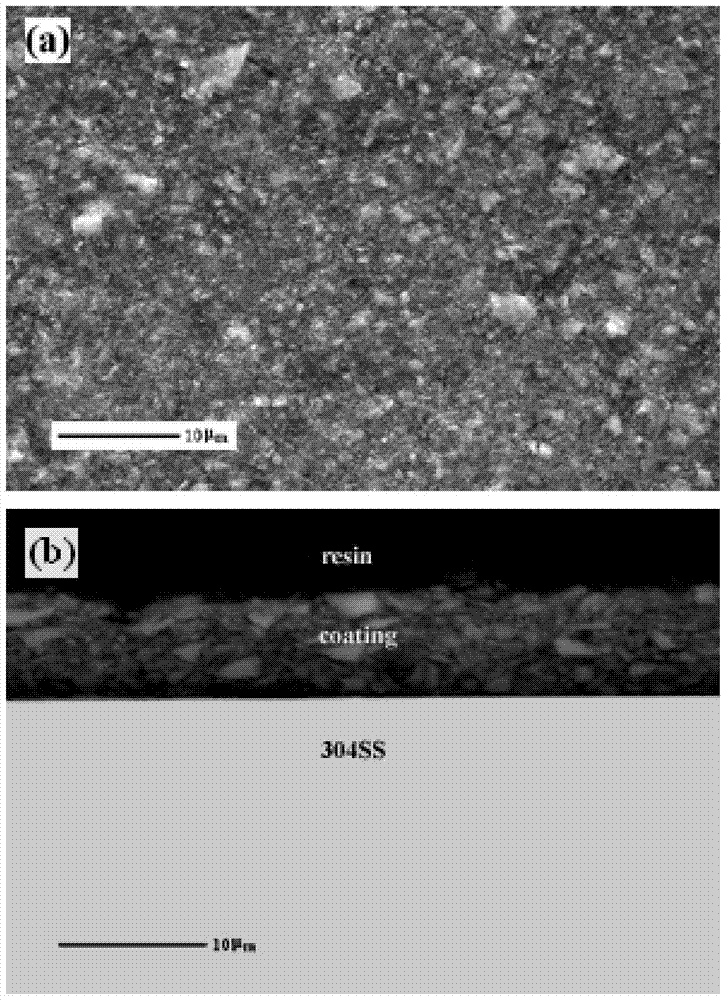

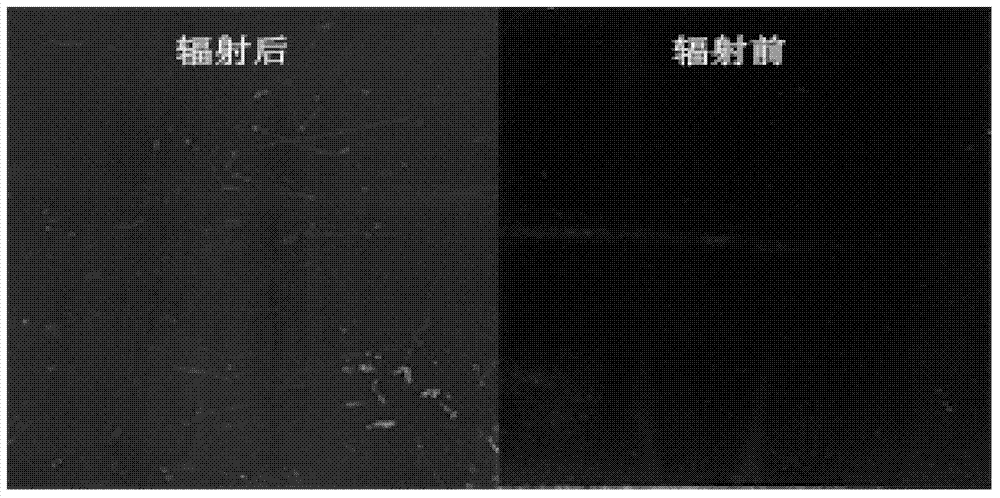

[0028] Weigh 1000 g of methyl silicone resin, 300 g of nano titanium powder (50 nm in particle size), 100 g of nano titanium dioxide powder (60 nm in particle size), 300 g of xylene and 500 g of zirconium silicate grinding beads with a particle size of 0.8 mm. Pre-mix methyl silicone resin, nano-titanium powder, nano-titanium dioxide powder, and xylene, add the above-mentioned pre-mixed mixture together with grinding beads into the circulating sand mill while stirring, stir at 2300rpm for 25 minutes, and take it out Obtain the A component. Weigh 300g of polyurethane resin and the above-mentioned component A and mix it evenly, and the viscosity will be 28s. Spray the paint on the surface of 304 stainless steel after sandblasting by spraying, and cure it at room temperature for 24 hours to obtain high temperature resistance, corrosion resistance and nuclear radiation resistance. protective coating.

[0029] In this embodiment, the performance parameters of the high temperature ...

Embodiment 2

[0032]Weigh 800 g of phenyl silicone resin, 200 g of nano titanium powder (80 nm in particle size), 80 g of nano titanium dioxide powder (50 nm in particle size), 400 g of xylene and 600 g of zirconium silicate grinding beads with a particle size of 0.8 mm. Pre-mix phenyl silicone resin, nano-titanium powder, nano-titanium dioxide powder, and xylene, add the above-mentioned pre-mixed mixture together with grinding beads into the circulating sand mill while stirring, stir at 2250rpm for 35min, take it out Obtain the A component. Weigh 250g of polyurethane resin and the above-mentioned component A and mix it evenly, and the viscosity will be 25s. Spray the paint on the surface of 304 stainless steel that has been sandblasted by spraying, and cure it at room temperature for 24 hours to obtain high temperature resistance, corrosion resistance and nuclear radiation resistance. protective coating.

[0033] In this embodiment, the performance parameters of the high temperature resis...

Embodiment 3

[0036] Weigh 1200 g of methylphenyl silicone resin, 180 g of nano titanium powder (40 nm in particle size), 150 g of nano titanium dioxide powder (60 nm in particle size), 400 g of xylene and 400 g of zirconium silicate grinding beads with a particle size of 0.8 mm. Pre-mix methylphenyl silicone resin, nano-titanium powder, nano-titanium dioxide powder, and xylene, and add the above-mentioned pre-mixed mixture together with grinding beads into a circulating sand mill while stirring, and stir at a speed of 1800rpm for 30 minutes. A component is obtained after taking out. Weigh 200g of polyurethane resin and the above-mentioned component A to mix evenly, and the viscosity is 22s. Apply the paint to the surface of GH907 high-temperature alloy steel after sandblasting by brushing, and cure it at room temperature for 24 hours to obtain high-temperature resistance and corrosion resistance. , Anti-nuclear radiation protective coating.

[0037] In this embodiment, the performance par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com