Ballasted railway ballast bed reinforcing device, system and method

A ballast and railway technology, applied in the field of railway infrastructure construction, can solve the problems of harmfulness to people and the environment, high cost, and difficult promotion in the railway industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

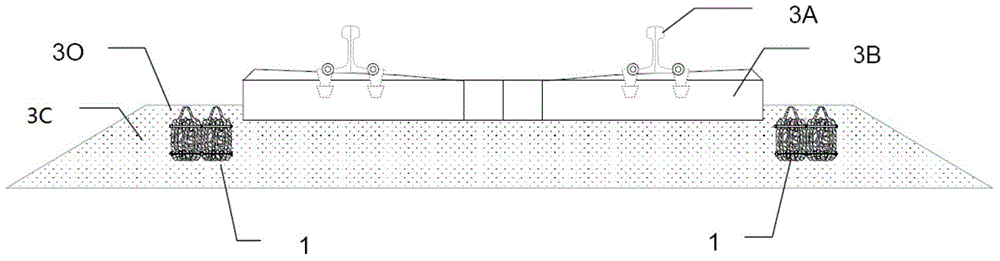

[0051] The following will combine Figure 1-14 Specific embodiments of the present invention are further described in detail.

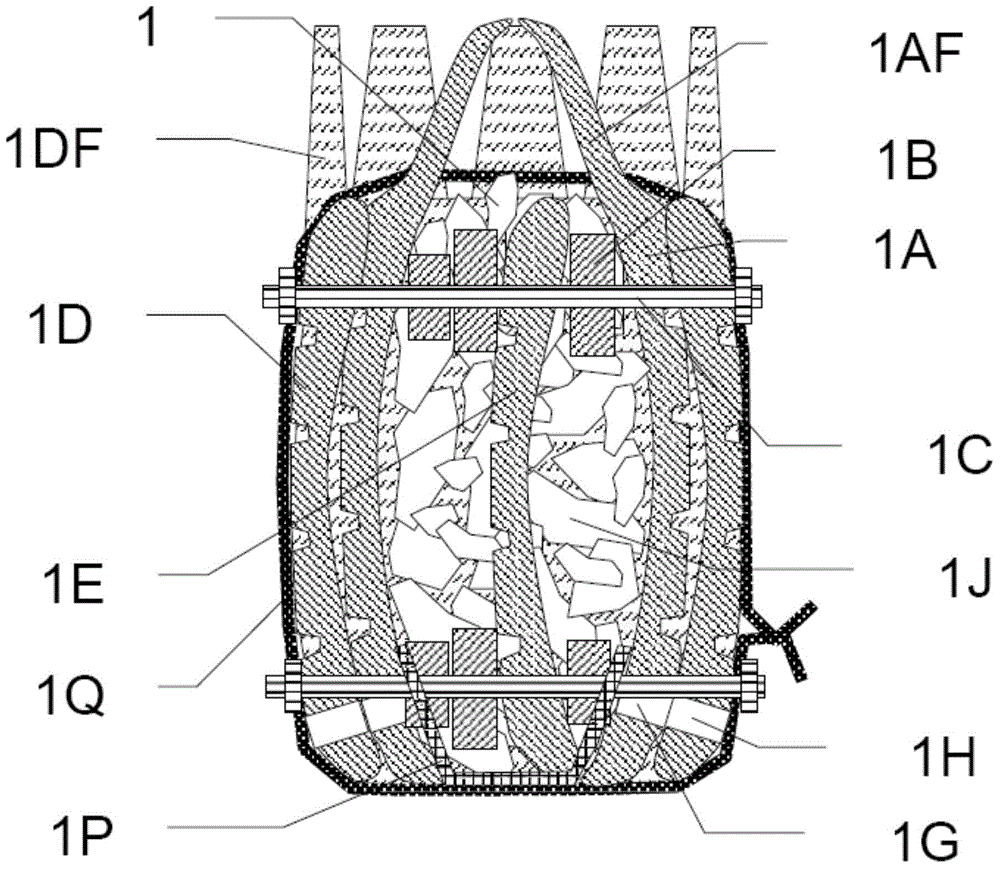

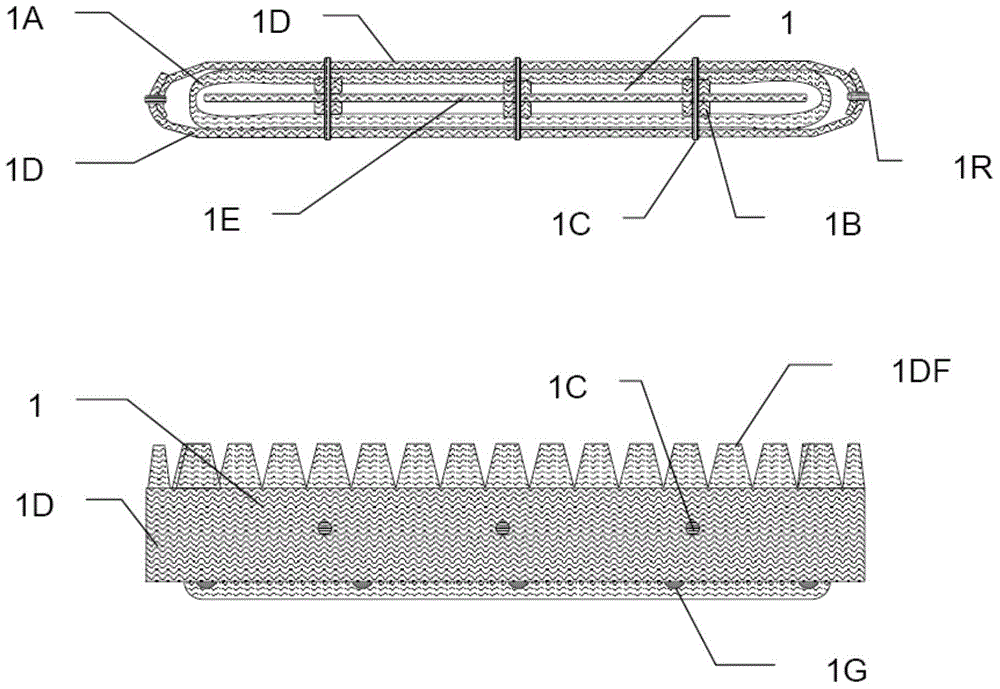

[0052] figure 1 According to a specific example of the present invention, it can be seen from the cross-sectional view of the single ballast brick 1 that it includes an elastic fixing sleeve 1A that can be transformed from waste vehicle tires, a set of distance maintaining pads 1B, a tensioning device 1C, Side wall reinforcement plate 1D, insulation plate 1E, elastic perforated bottom bracket 1P and locking unit 1Q.

[0053] Depend on figure 1 , figure 2As shown, through the additional distance maintaining pad 1B and tensioning device 1C, the tire can be changed from a circular shape to an elastic fixing sleeve 1A approaching a strip rectangle. The side wall reinforcement plate 1D helps the elastic fixing sleeve 1A to further maintain the desired shape. It needs to be stated that the present invention covers other elastic fixing sleeves of other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com