Construction method for opening hole between rectangular pipe jacking channels

A rectangular pipe jacking and construction method technology, which is applied in tunnels, earthwork drilling, tunnel lining, etc., can solve the problems of construction difficulties such as the inability to connect traffic, pedestrians, and pipe jacking passages, and achieve stable and reliable passage structures. The effect of high construction efficiency and small damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In this embodiment, the construction method of opening holes between rectangular pipe jacking passages of the present invention is described by taking the construction of a connecting passage between subways in a certain subway as an example.

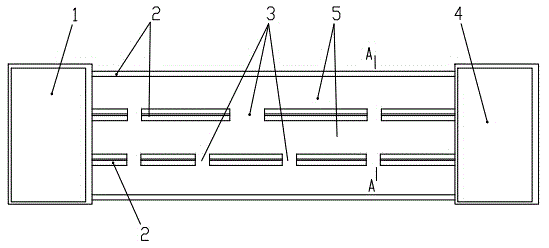

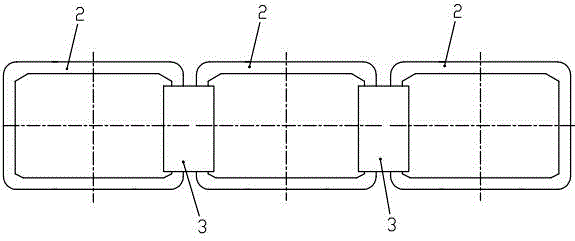

[0041] Such as figure 2 As shown, an independent rectangular pipe jacking channel 5 formed by three rectangular pipe jacking pipes 2 is arranged between the originating well 1 and the receiving well 4, and now it is intended to open up the three rectangular pipe jacking channels 5, as image 3 As shown, a communication channel 3 is established between the opened rectangular pipe jacking passages. The construction method for opening holes between the rectangular pipe jacking passages of this embodiment includes the following steps:

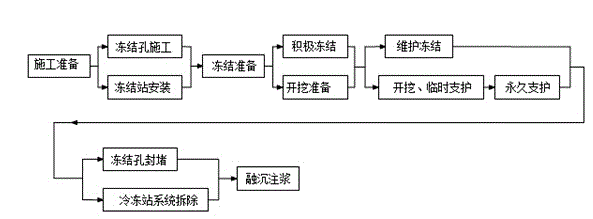

[0042] (1) Construction preparation: understand the geotechnical conditions, hydrogeological conditions and surrounding pipeline conditions near the rectangular pipe jacking to be constructed, and pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com