Gasoline and natural gas double-fuel double-jetting type engine

A natural gas and engine technology, applied in the field of gasoline and natural gas dual-fuel dual-injection engines, can solve the problems of high emission of unburned methane, slow combustion rate, low compression ratio, etc., and achieve the goals of improved thermal efficiency, low development cost and saving oil resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

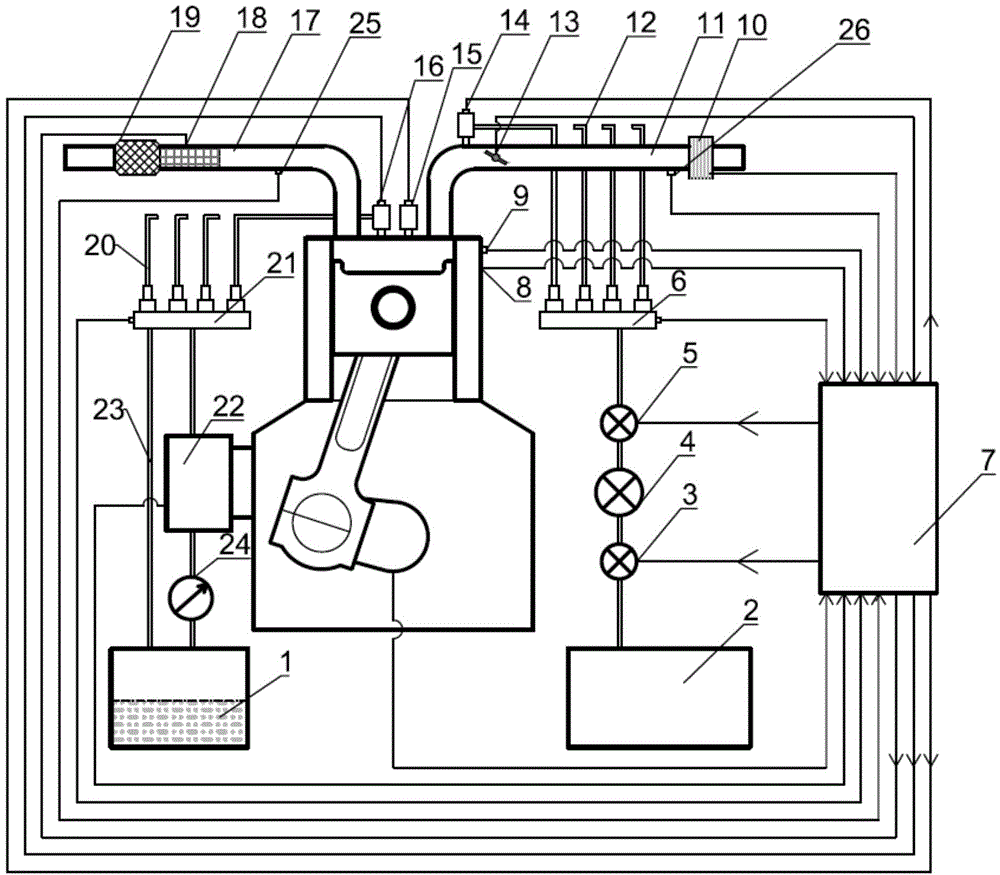

[0011] Such as figure 1 As shown, the present invention includes a gasoline fuel tank 1, a cooling water temperature sensor 8, a knock sensor 9, an air mass flow sensor 10, an intake pipe 11, an electronic throttle valve 13, a spark plug 15, an electronically controlled gasoline injector 16, and an exhaust pipe 17. Particulate filter 18, three-way catalytic converter 19, gasoline high-pressure oil pipe 20, gasoline high-pressure oil rail 21, gasoline high-pressure oil pump 22, gasoline oil return pipe 23, gasoline filter 24, air-fuel ratio sensor 25, intake air temperature Pressure sensor 26, natural gas storage tank 2, natural gas high pressure stop valve 3, natural gas pressure reducing valve 4, natural gas low pressure stop valve 5, natural gas injection rail 6, electronic control unit 7, natural gas pipeline 12, electronically controlled natural gas injector 14 , the cooling water temperature sensor 8 and the knock sensor 9 are respectively arranged on the engine body, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com