Engine hydraulic mount assembly

A hydraulic mount and engine technology, which is applied in the direction of power devices, mechanical equipment, jet propulsion devices, etc., can solve the problems of complex overall structure, high manufacturing cost, and complicated procedures, so as to reduce product weight, reduce assembly processes, and avoid large The effect of area damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

[0039] Dynamic stiffness: Relative to the definition of static stiffness, static stiffness refers to the amount of deformation produced by an object under a certain external force, and dynamic stiffness refers to the amount of deformation produced by an object under the action of an external force at a certain frequency.

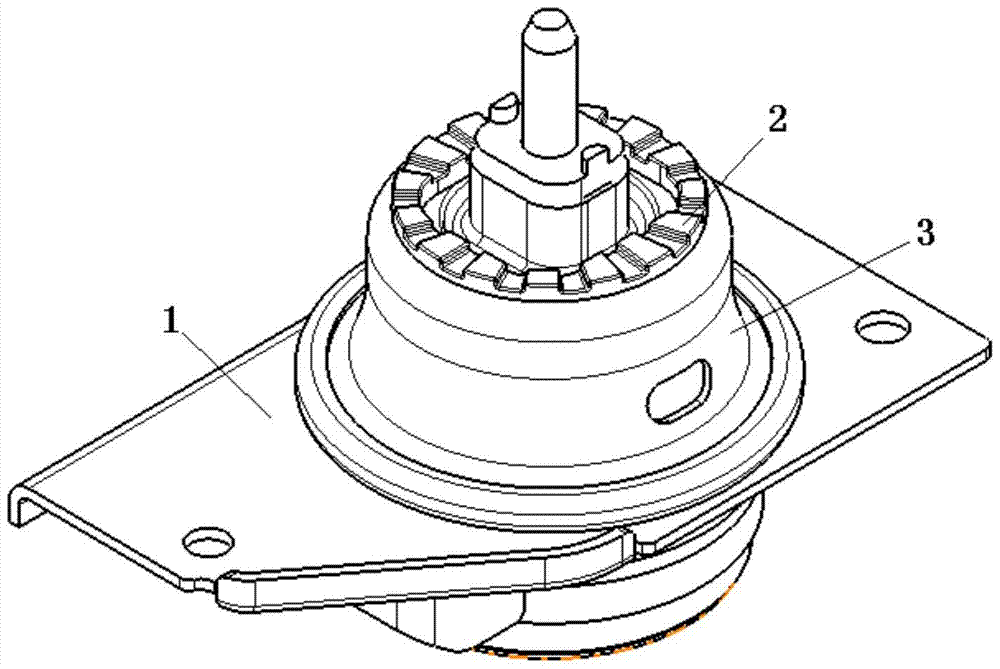

[0040] The invention provides an engine hydraulic mount assembly, such as image 3 with Figure 4 As shown, it includes a main spring 105, a crash pad 104, a dust cover 103, a spoiler 106, a flow channel cover 108, a flow channel 112, a lower liquid chamber 110, a mounting bracket 101, a decoupling diaphragm 109, an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com