Restrained induction heating electromagnetic riveting device and method

An induction heating and electromagnetic riveting technology, which is applied in the field of constrained induction heating electromagnetic riveting devices, can solve the problems of heat conduction damage to composite materials, rivet head cracking riveting force, and rivets with upset heads, etc., to reduce damage caused by excessive temperature , high forming efficiency, and the effect of improving riveting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

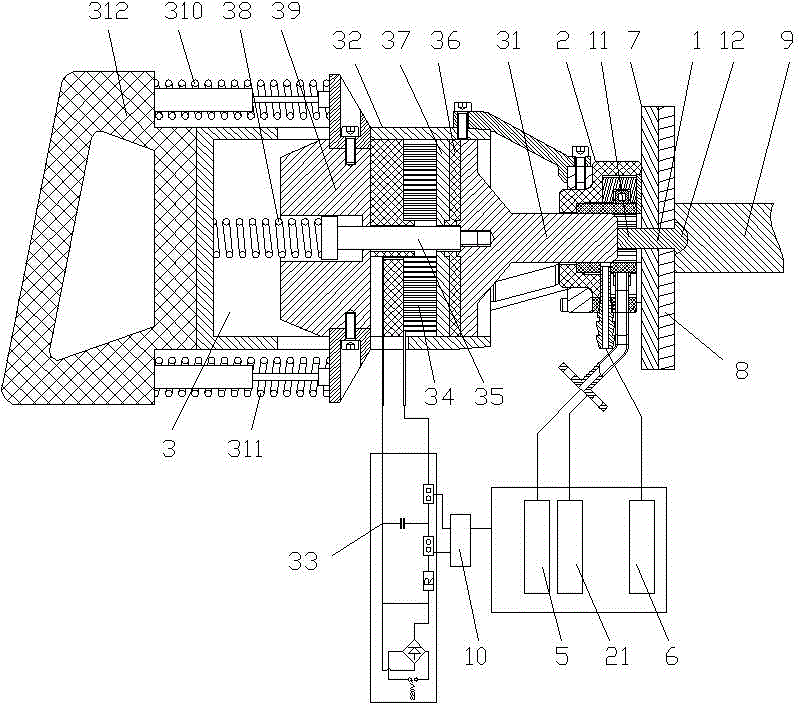

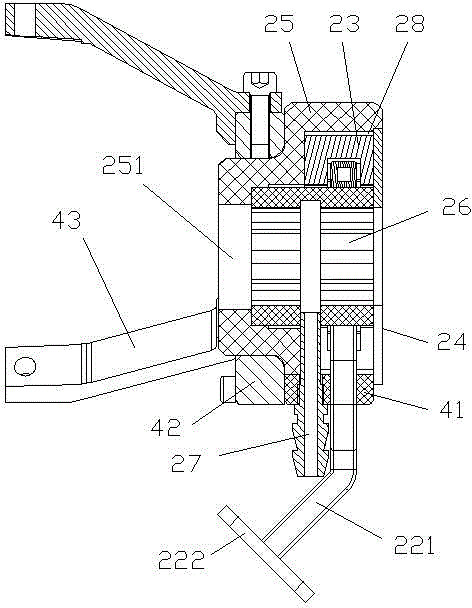

[0034] Such as Figure 1~9As shown, a constrained induction heating electromagnetic riveting device includes a constrained induction heater 2 for quickly heating the head 11 of the rivet 1 to be formed. The heating coil 22, the induction heating coil 22 is provided with a number of ferrites 23 for confining the magnetic field, and the confinement induction heater 2 also includes a set of ferrites 23 arranged outside the induction heating coil 22 and the ferrite 23 The silicon steel sheet 24 that shields the leakage magnetic field, the restraint induction heater 2 is sleeved at the end of the amplifier 31 of the electromagnetic riveting gun 3 and is fixedly connected with the shell of the electromagnetic riveting gun 3 through the support frame 4, and the amplifier 31 is relatively bound to the induction heater 2 Movement to form the head 11 of the heated rivet 1 to be formed.

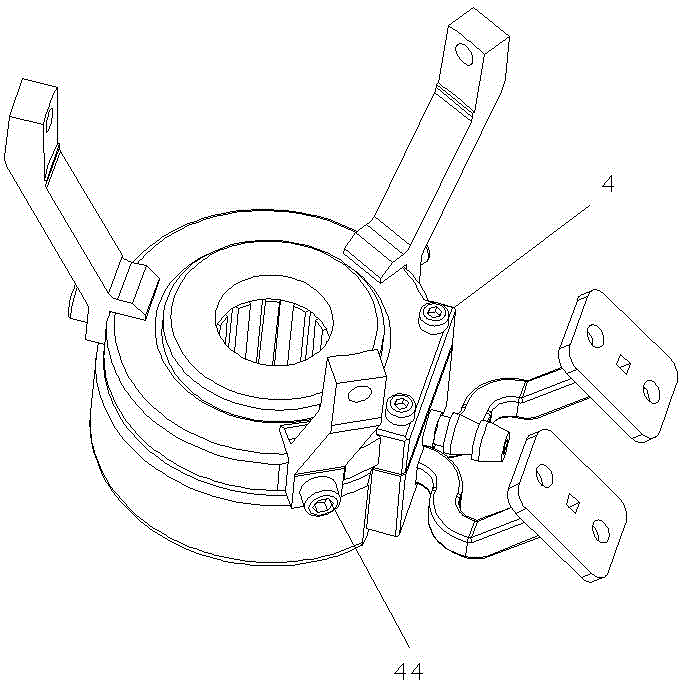

[0035] In the present invention, the support frame 4 includes a support plate 41 fixed on the two p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com