Sand mold plunge milling processing method and plunge milling equipment

A sand molding and plunge milling technology, applied in metal processing equipment, casting molding equipment, casting molds, etc., can solve the problems of long processing time and reduce tool service life, and achieve increased equipment service life, reduced tool wear, and strength. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

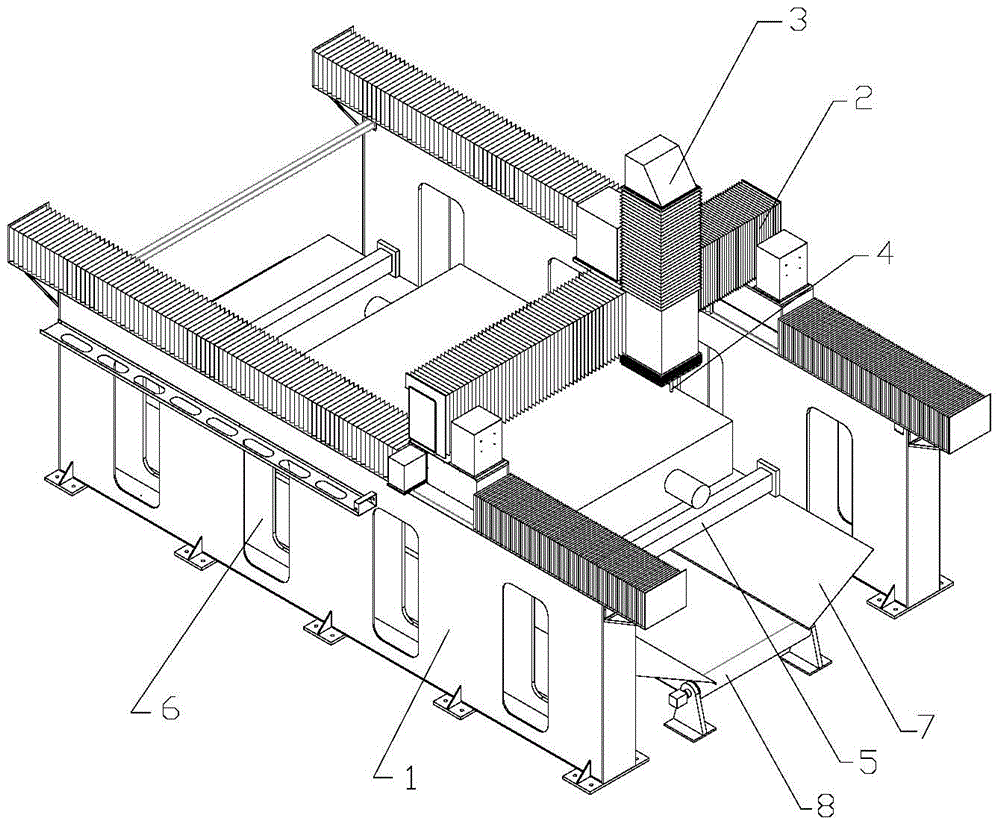

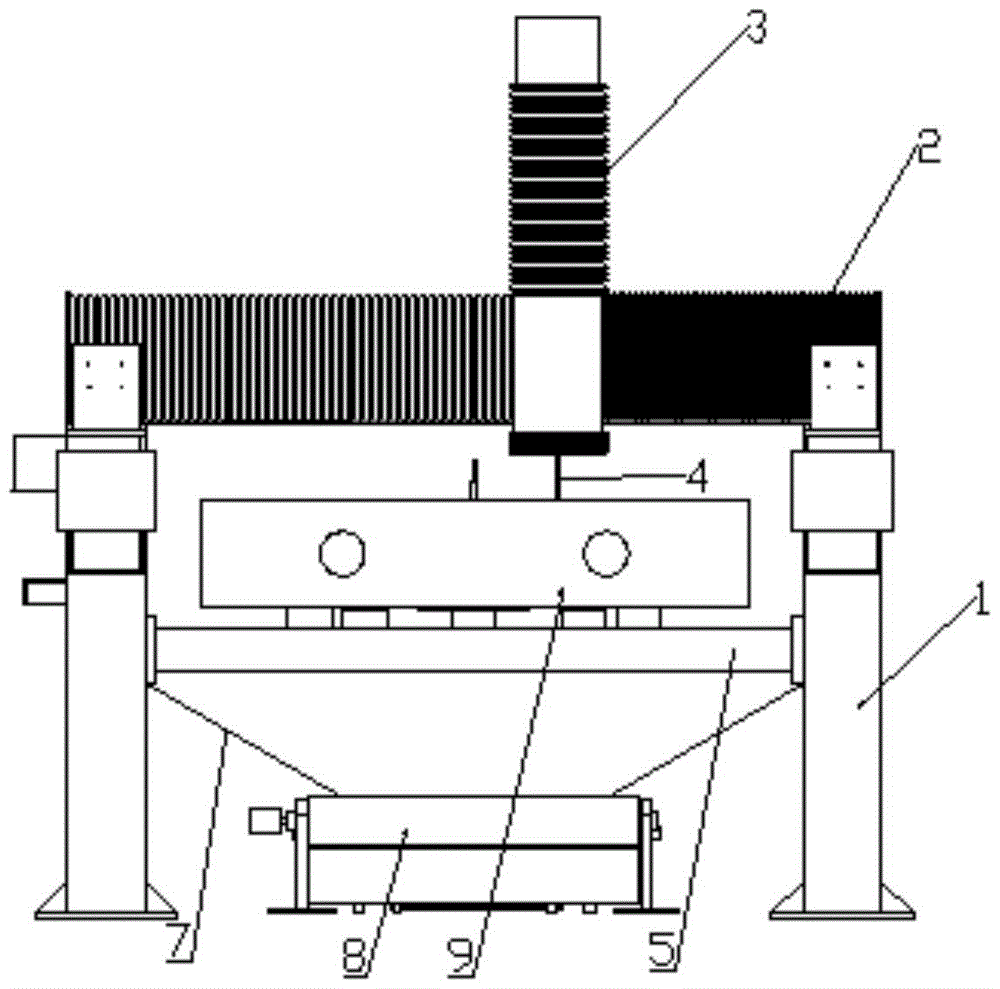

[0034] Such as figure 1 , figure 2 As shown, the sand mold inserting and milling equipment includes Y-axis wallboard 1, X-axis beam 2, Z-axis column 3, Y-axis wallboard 1 is set on both sides of X-axis beam 2, and X-axis beam 2 is set on two Y-axis Above the wall panel 1, the X-axis beam 2 is provided with a Z-axis column 3, and the Z-axis column 3 is provided with a tool 4. A plurality of viewing windows 6, a waste sand collection sloping plate 7 and a sand discharge device 8 are arranged under the workbench 5. The distance between the workbench 5 and the sand discharge device 8 is 200mm-800mm.

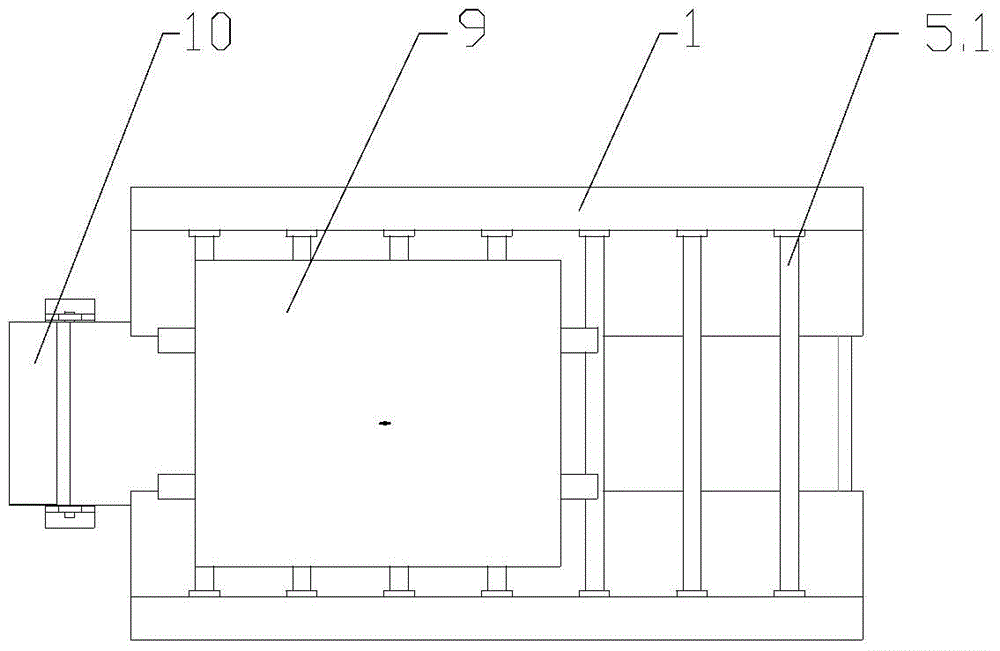

[0035] Such as image 3 As shown, the workbench 5 is a beam structure, and a plurality of beams 5.1 are arranged in parallel to form a working plane. The two ends of the beams 5.1 are fixed on the Y-axis wallboard 1, and the distance between the beams 5....

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap