Cladding mould capable of enhancing combination degree of outer winding pipe of krah pipe and krah pipe structure

A technology of winding tube and carat tube, applied in the field of carat tube, can solve the problems that single-wall corrugated tube cannot be bonded, there are hidden safety hazards, waste and other problems, and achieve the effects of good economic benefits, convenient processing and operation, and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

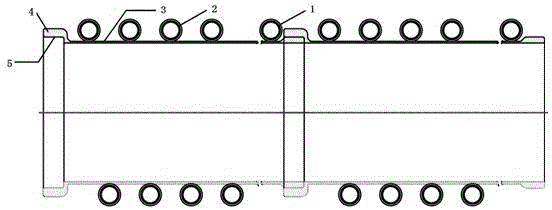

[0027] Such as figure 1 As shown, a carat tube structure of this embodiment includes an outer winding tube cladding layer 1, an outer winding tube 2, an inner wall PE layer 3, an HDPE solid wall tube 4 and a pre-embedded heating wire 5 from the outside to the inside. The wrapping layer 1 of the winding pipe and the outer winding pipe 2 are covered by vacuum.

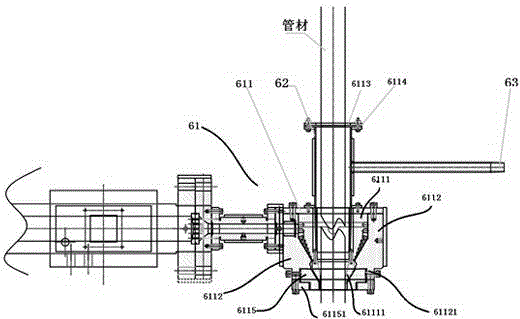

[0028] This embodiment adopts a kind of coating mold 6 that can enhance the bonding degree of the outer winding tube of the carat tube to realize the above-mentioned carat tube structure, such as figure 2 As shown, it includes an overmold main body 61 for cladding, a vacuum cylinder 62 and a vacuum pump 63. The vacuum cylinder 62 is fixed through the overmold main body 61, and the vacuum pump 63 is connected with the vacuum cylinder 62. During the cladding process, through Vacuumize, so that the outer winding pipe 2 and the cladding layer are tightly combined to enhance the hardness of the carat pipe; the main body of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com