Micro spring cantilever beam micro heater with soaking plate and preparation technology thereof

A technology of micro-heater and cantilever beam, which is applied in the field of micro-spring-type cantilever beam with vapor chamber micro-heater and its preparation technology, can solve the problems of uneven temperature of reaction unit, no stress release of cantilever beam, etc., and achieve suitable It is suitable for large-scale production, reduces heat conduction and heat dissipation, and improves space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

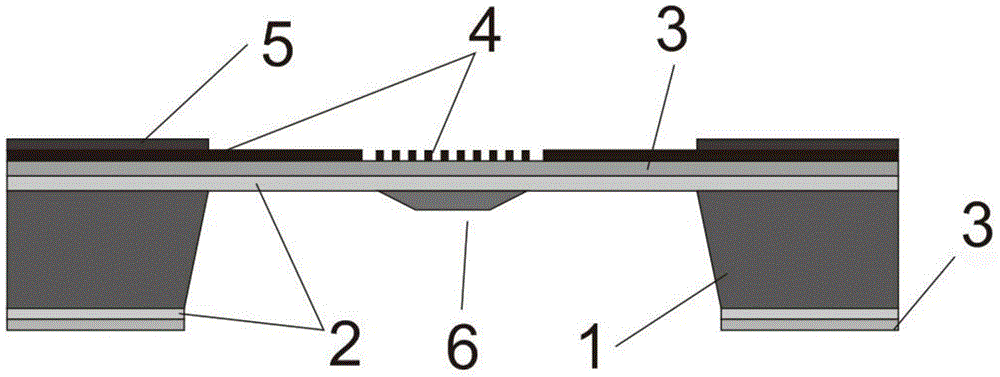

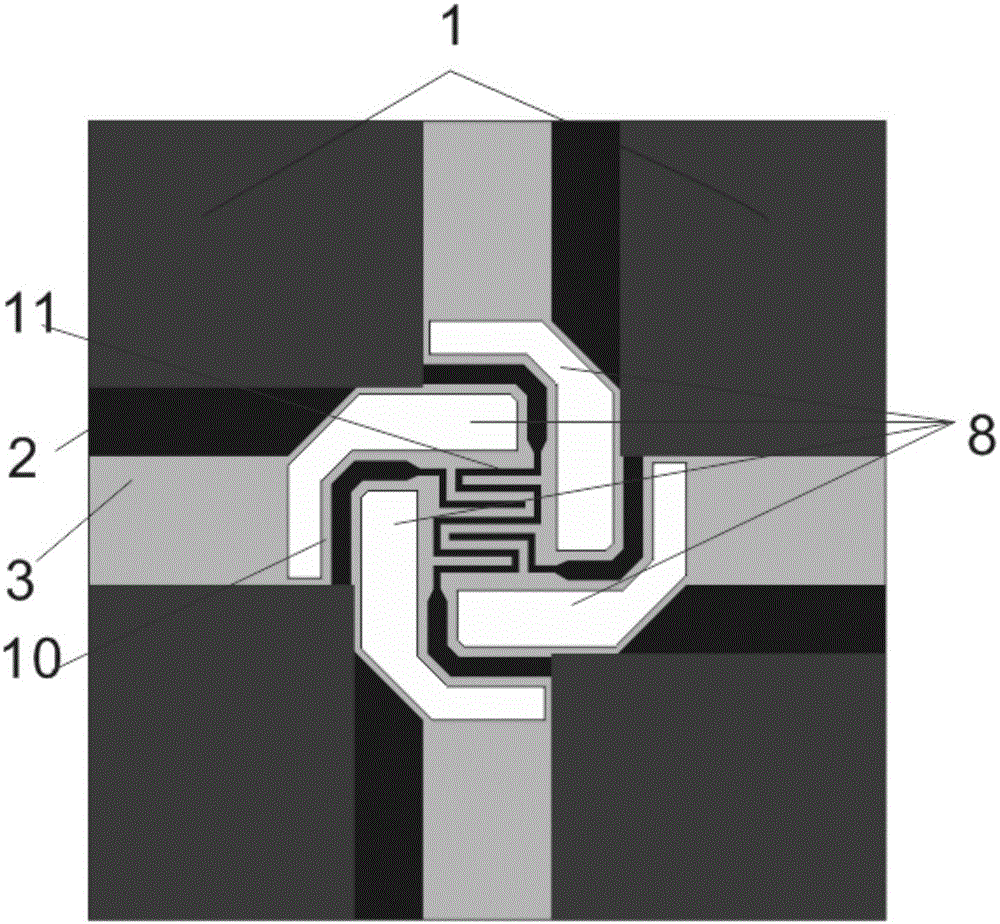

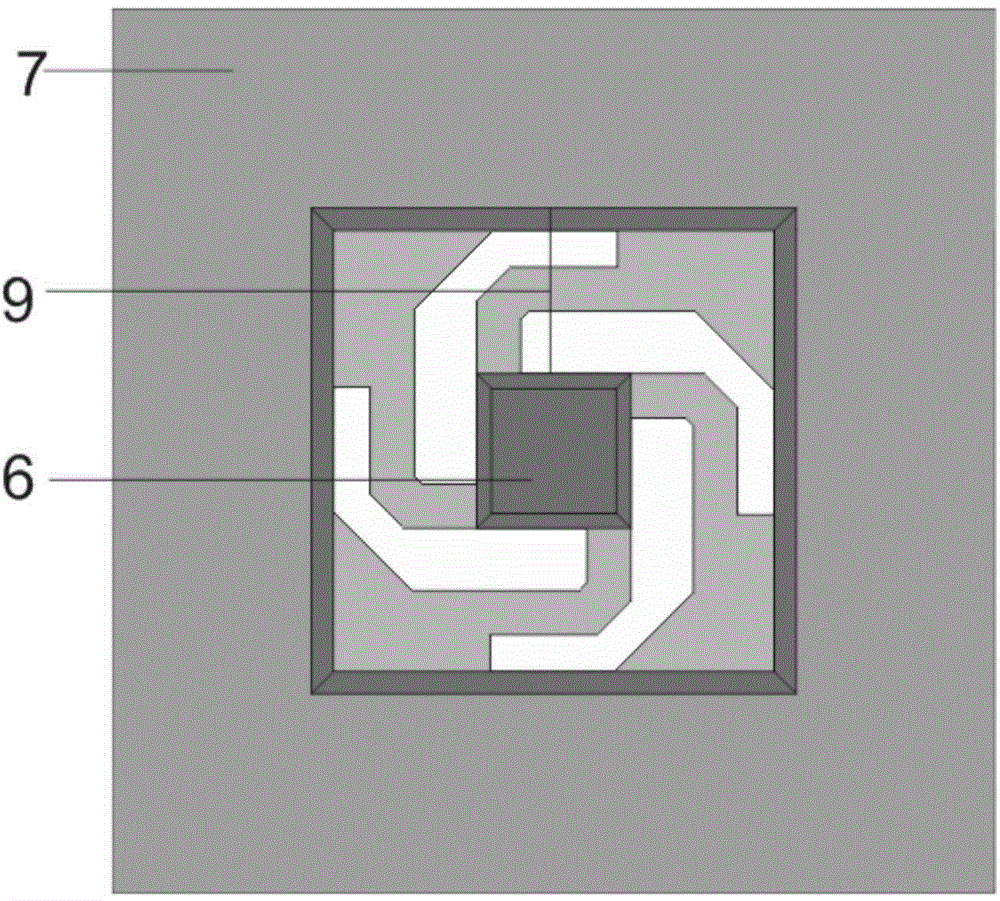

[0042] Such as Figure 1~3 As shown, a micro-spring type cantilever beam with a vapor chamber micro-heater includes a silicon base 1, an insulating film, a heating unit 4, and a soaking plate 6; the silicon base 1 is composed of The middle part of the silicon base 1 is provided with a through hole, the insulating film covers the base and the through hole, and the part of the insulating film covering the through hole is provided with an air gap 8 And form cantilever beam 10; Described heating unit 4 comprises heating wire 11 and electrode 5, and heating wire 11 width is 20 μm, and length is 1.5mm, and electrode 5 is Au electrode, and described heating wire 11 is arranged on described cantilever beam 10 , the electrode 5 is arranged on the insulating film, the heating unit 4 has the functions of heating and temperature measurement at the same time, and can be powered by a DC or AC power supply; the soaking plate 6 is located in the through hole and connected to the Below the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com