Size grading method for graphene material

A grading method and graphene technology, applied in the field of graphene materials, can solve the problems of inability to separate large and small pieces of graphene oxide, insufficiently uniform pore size distribution, long pore channels, etc., and achieve the effect of significant size separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

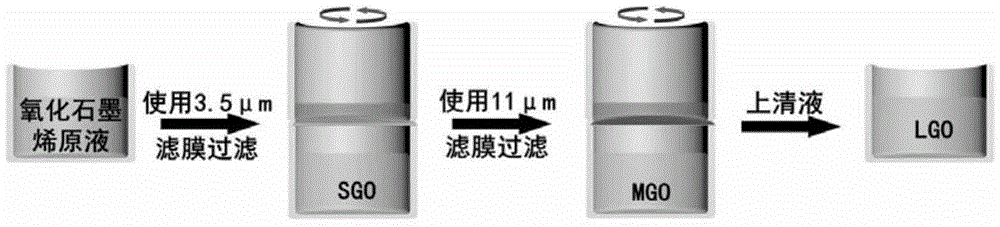

[0047] Embodiment 1, grading graphene oxide sheet according to size:

[0048] 1) Preparation of graphene oxide: 1.0 g of 325 mesh natural graphite powder was mixed with 23 mL of 96-98 wt % concentrated sulfuric acid in an ice-water bath, and after stirring evenly, 9.0 g of potassium permanganate was slowly added. Raise the temperature of the system to 35°C, keep it stable for half an hour, add 50mL deionized water, continue stirring for 15 minutes, add 150mL deionized water, 5mL 3wt% H 2 o 2 . The resulting bright yellow solution was filtered and washed with 100 mL of aqueous HCl (wherein the volume ratio of hydrochloric acid and water was 1:9). The resulting solid was dried in air and diluted, dialyzed in deionized water for one week, then ultrasonically stripped, and centrifuged twice at 3000rpm for 30min to remove the substrate to obtain a dispersion of monolayer graphene oxide;

[0049] 2) Grading graphene oxide flakes according to size: the dispersion of single-layer g...

Embodiment 2

[0066] Embodiment 2, classifying graphene oxide sheet according to size:

[0067] Using the dispersion of single-layer graphene oxide prepared in Example 1 as raw material, dilute it to 0.2 mg / mL, and use only a 3.5 μm membrane to separate the two components. The obtained results are as follows: Figure 8 As shown, the size difference between the obtained two components is obvious, and more than 90% of the size distribution of the 3.5 μm filter is smaller than 7 μm, while more than 90% of the intercepted size is larger than 6 μm.

Embodiment 3

[0068] Embodiment 3, classifying graphene oxide sheet according to size:

[0069] Using the dispersion of single-layer graphene oxide prepared in Example 1 as a raw material, dilute it to 0.2 mg / mL, and only use a 5.5 μm membrane to separate the two components. The obtained results are as follows: Figure 9 As shown, the size difference between the two components obtained is obvious, and more than 90% of the size distribution of the 5.5 μm filter is smaller than 11 μm, while more than 90% of the intercepted size is larger than 9 μm;

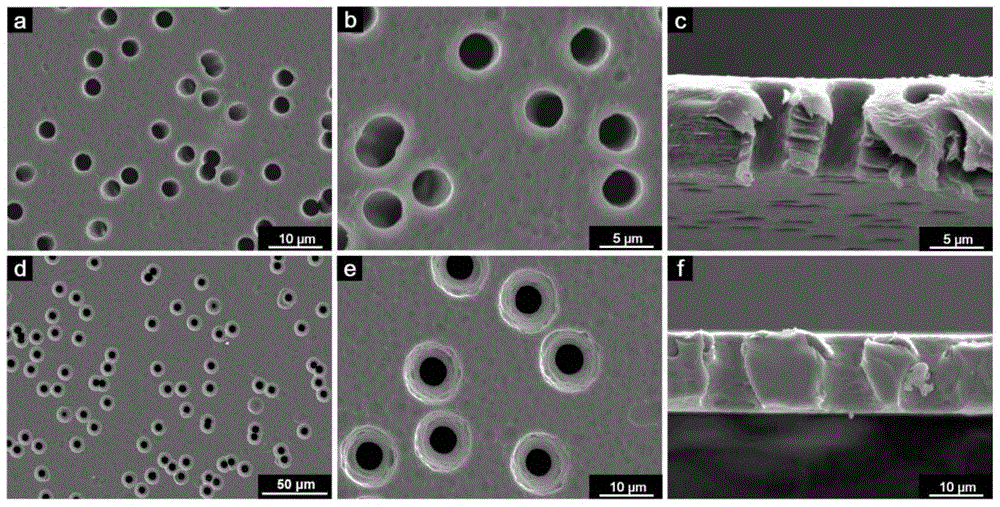

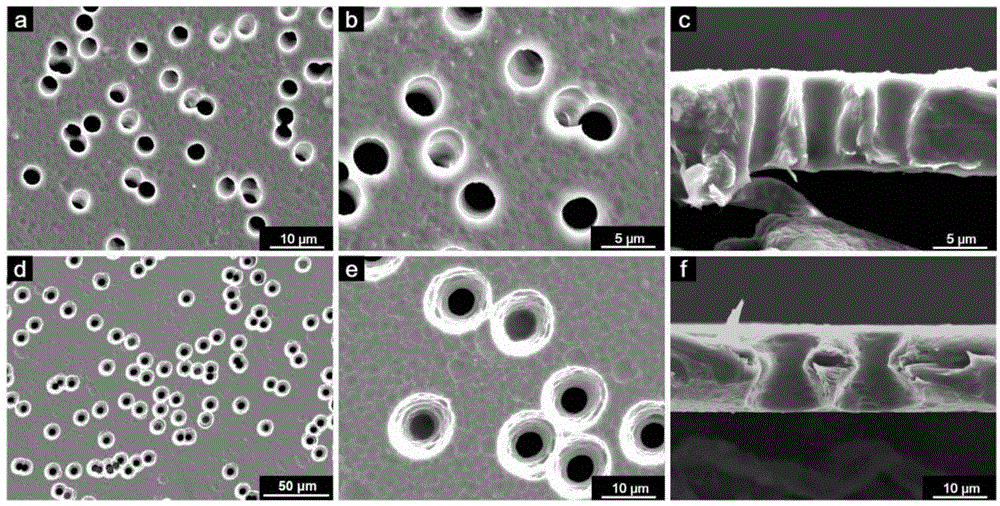

[0070] Moreover, after being rinsed with a simple solvent (such as water and ethanol, etc.) after use, the filter membrane can be used repeatedly without graphene oxide (GO) residues (such as Figure 10 ), Figure 10 The picture in the upper middle row is the SEM image of the unused filter membrane, Figure 10 The pictures in the middle and lower rows are SEM images of the used and washed filter membranes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com