Glass-ceramic with nanocrystal clusters distributed in glass phase and method for preparing same

A technology of glass-ceramic and nano-crystal, which is applied in the field of glass-ceramic and its preparation, can solve the problems of weakening glass phase performance, comprehensive utilization rate of less than 10%, and decline of glass-ceramic material performance, and achieve the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

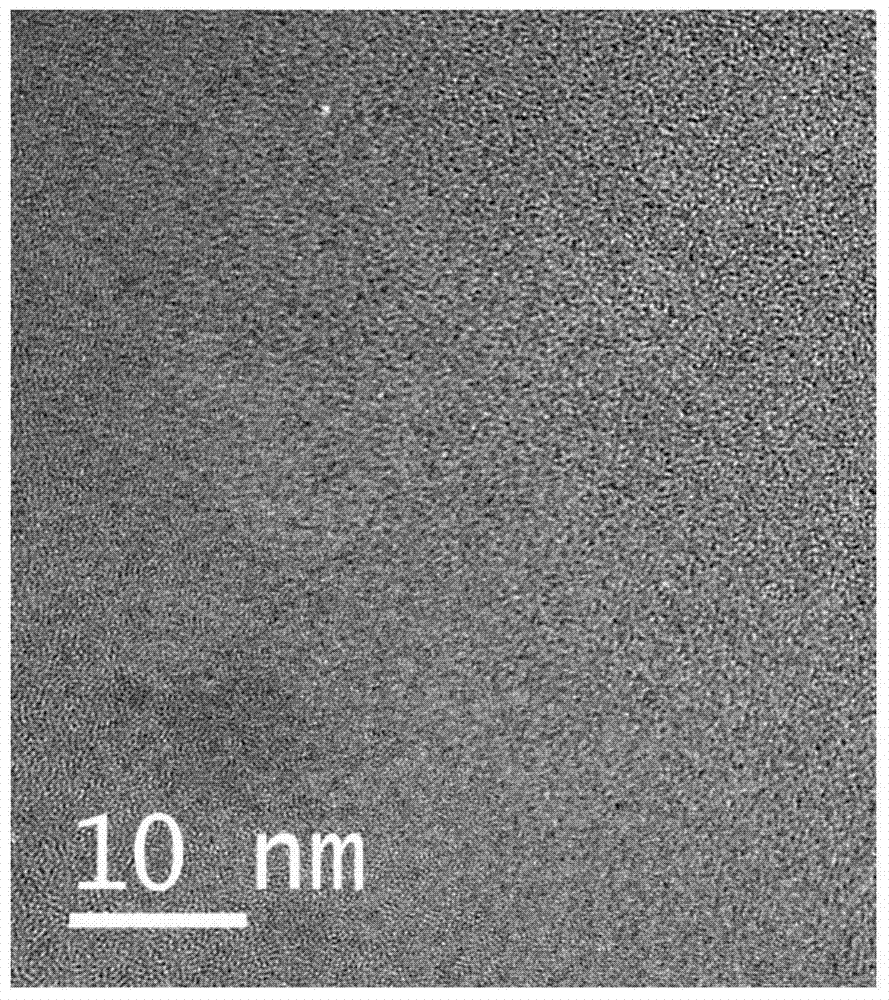

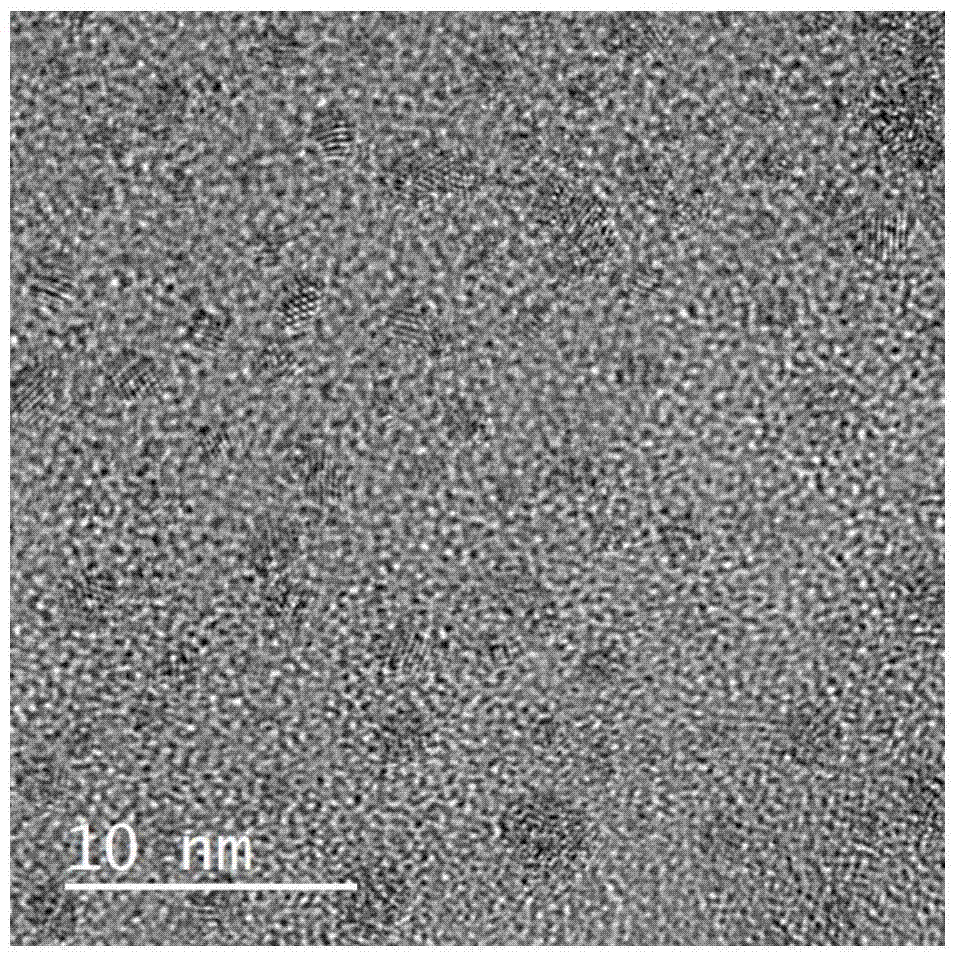

[0035] A method for preparing glass-ceramics distributed with nanocrystal clusters in a glass phase:

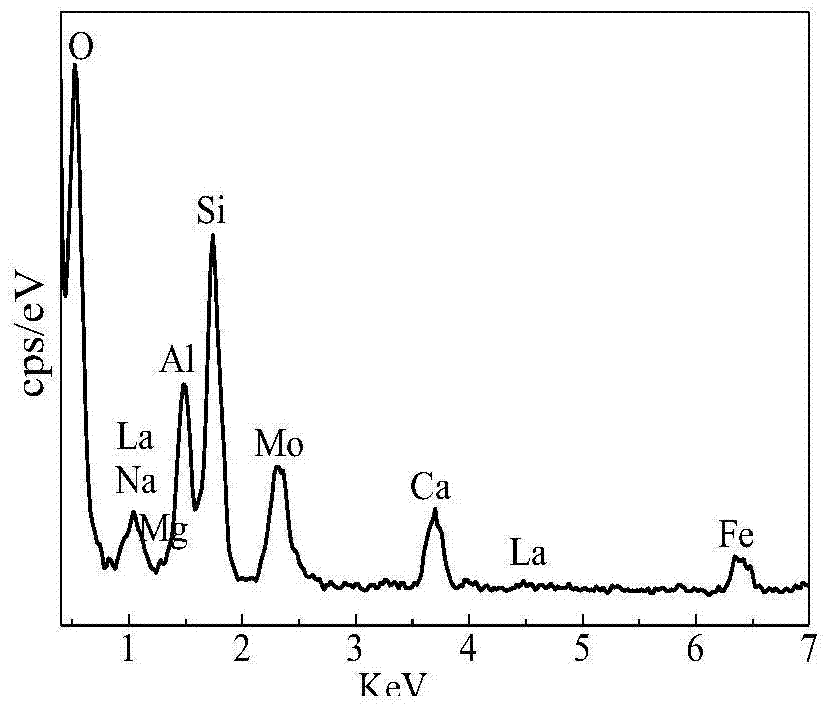

[0036] (1) According to the weight ratio of the chemical composition of the glass-ceramics: 50% SiO 2 , 20% CaO, 5.04% Al 2 o 3 , 7.73% MgO, 0.55% Na 2 O, 2% B 2 o 3 , 3%CaF 2 , 3.43% Fe 2 o 3 , 0.25%Cr 2 o 3 and 8% La 2 o 3 , the weight ratio of raw materials: 50% Baiyun Obo tailings, 15% fly ash, 15% SiO 2 , 6.75% CaO, 2% borax, 3% CaF 2 , 0.25%Cr 2 o 3 and 8% La2 o 3 ;

[0037] (2) Mixing: Put the raw materials with a good ratio into the ball mill for 60 minutes and grind to below 40 mesh;

[0038] (3) Melting: Put the uniformly mixed raw materials into the crucible, and use a high-temperature resistance furnace to melt, clarify and homogenize at 1400-1500°C;

[0039] (4) Forming and annealing: casting the melted and clarified glass solution on a stainless steel mold to form a basic glass sample, annealing the basic glass sample at 600°C for 4 hours and c...

Embodiment 2

[0044] A method for preparing glass-ceramics distributed with nanocrystal clusters in a glass phase:

[0045] (1) Weight ratio of raw materials: 50% Baiyun Obo tailings, 15% fly ash, 22% SiO 2 , 7.05% CaO, 2% borax, 3% CaF 2 , 0.25%Cr 2 o 3 and 0.7% La 2 o 3 +CeO 2 ;

[0046] (2) Mixing: Put the raw materials with a good ratio into the ball mill for 60 minutes and grind to below 40 mesh;

[0047] (3) Melting: Put the uniformly mixed raw materials into the crucible, and use a high-temperature resistance furnace to melt, clarify and homogenize at 1400-1500°C;

[0048] (4) Forming and annealing: casting the melted and clarified glass solution on a stainless steel mold to form a basic glass sample, annealing the basic glass sample at 600°C for 4 hours and cooling with the furnace to eliminate the stress in the sample;

[0049] (5) Heat treatment: Nucleate the basic glass sample after annealing at 680°C for 2 hours and crystallize it at 860°C for 2 hours to prepare a glass-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com