Intermediate alloy material and preparation method thereof

A master alloy and rare earth technology, which is applied in the field of master alloy materials and its preparation, can solve the problems of low bearing force and low strength of magnesium alloys, and achieve the effects of improving creep performance, increasing grain boundary strength, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

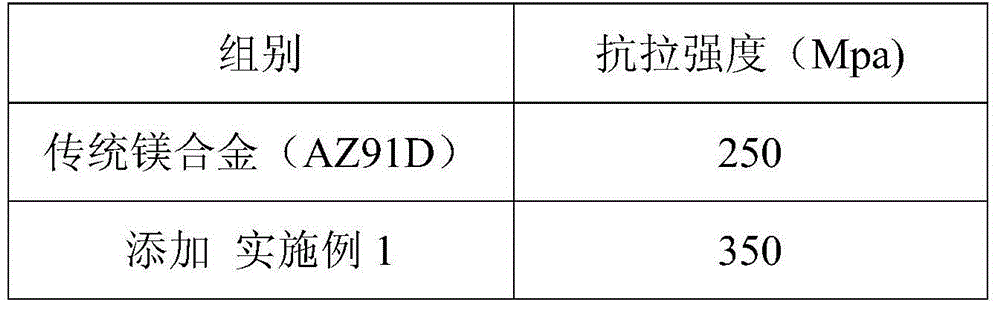

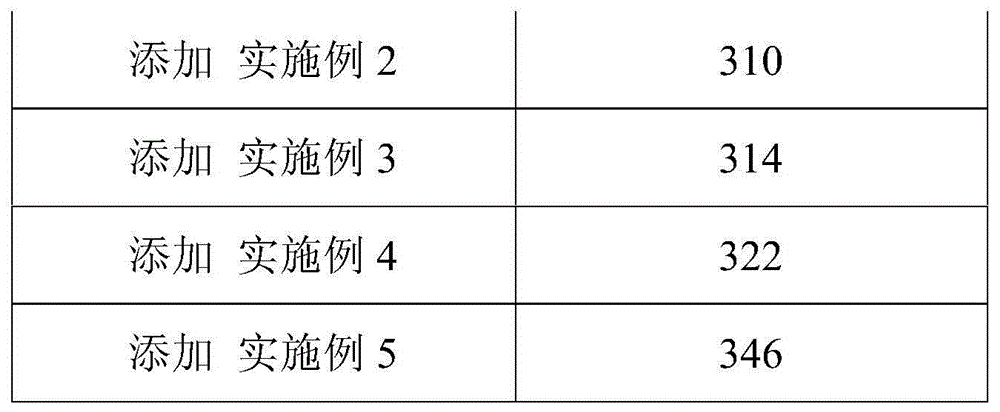

Examples

Embodiment 1

[0024] The percentage by weight of each component of the master alloy material in Example 1 of the present invention is: magnesium 66wt%, red phosphorus 32wt%, silicon carbide 1.5wt%, rare earth 0.5wt%.

[0025] The preparation method of the master alloy material of the embodiment of the present invention 1, comprises the following steps:

[0026] 1) Prepare magnesium powder, red phosphorus powder, silicon carbide particles and rare earth elements according to weight percentage under conventional conditions;

[0027] 2) Mix and stir the four kinds of powders with moderate weight proportions under the condition of about 10°C, and add an appropriate amount of absolute ethanol during stirring; the stirring time is 30 minutes;

[0028] 3) Put the evenly stirred powder into a mold with a capacity of 1 kg, press it into small pieces and dry it; when pressing, the temperature is about 20°C and the pressure is 80KN;

[0029] 4) Place the completed small block in a vacuum heating furn...

Embodiment 2

[0032] The percentage by weight of each component of the master alloy material in Example 2 of the present invention is: magnesium 71wt%, red phosphorus 28wt%, silicon carbide 0.9wt%, rare earth 0.1wt%.

[0033] The preparation method of the master alloy material of the embodiment of the present invention 2, comprises the following steps:

[0034] 1) Prepare magnesium powder, red phosphorus powder, silicon carbide particles and rare earth elements according to weight percentage under conventional conditions;

[0035] 2) Mix and stir the four kinds of powders with moderate weight proportions under the condition of about 10°C, and add an appropriate amount of absolute ethanol when stirring; the stirring time is 22 minutes;

[0036] 3) Put the evenly stirred powder into a mold with a capacity of 1 kg, press it into small pieces and dry it; when pressing, the temperature is about 20°C and the pressure is 75KN;

[0037] 4) Place the completed small block in a vacuum heating furnac...

Embodiment 3

[0040] The percentage by weight of each component of the master alloy material in Example 3 of the present invention is: magnesium 68wt%, red phosphorus 31wt%, silicon carbide 0.7wt%, rare earth 0.3wt%.

[0041] The preparation method of the master alloy material of the embodiment of the present invention 3, comprises the following steps:

[0042] 1) Prepare magnesium powder, red phosphorus powder, silicon carbide particles and rare earth elements according to weight percentage under conventional conditions;

[0043] 2) Mix and stir the four kinds of powders with moderate weight proportions under the condition of about 10°C, and add an appropriate amount of absolute ethanol when stirring; the stirring time is 24 minutes;

[0044] 3) Put the evenly stirred powder into a mold with a capacity of 1 kg, press it into small pieces and dry it; the temperature during pressing is about 20°C, and the pressure is 78KN;

[0045] 4) Place the completed small block in a vacuum heating furn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com