Method of improving anti-ultraviolet performance of M5 fiber with tubular titanium dioxide

A titanium dioxide, anti-ultraviolet technology, used in fiber processing, fiber types, textiles and papermaking, etc., can solve the problems of low anti-ultraviolet performance of M5 fibers, easy to be damaged by light, etc., to achieve remarkable anti-ultraviolet performance, low price, anti-ultraviolet Ability-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

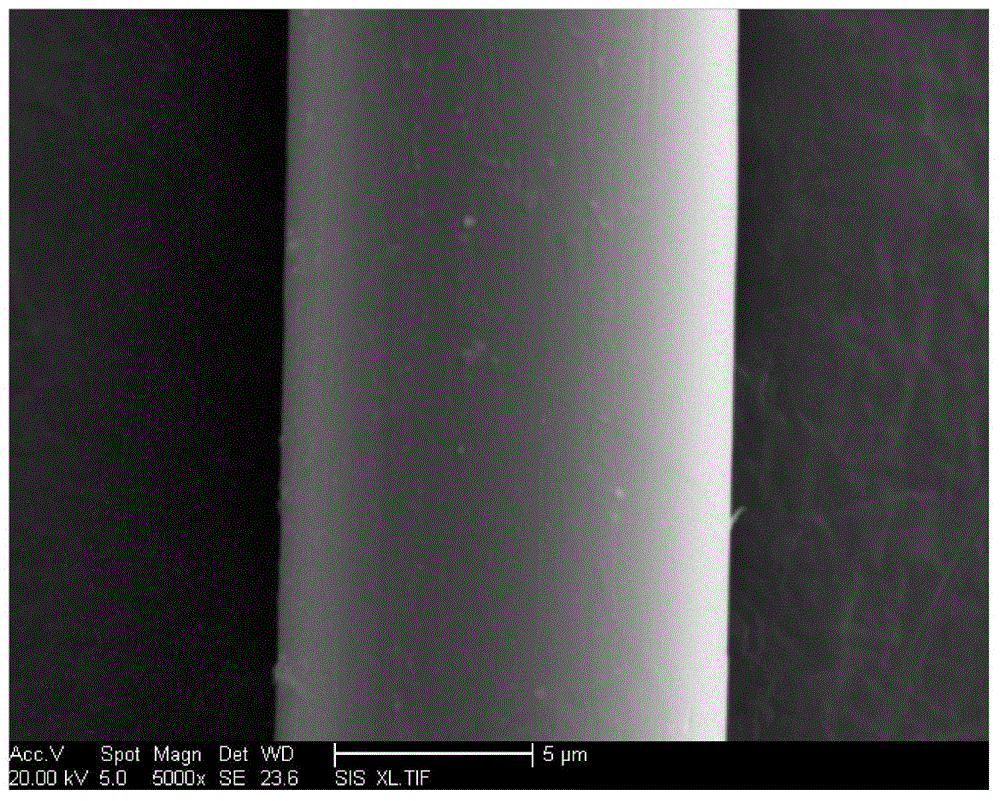

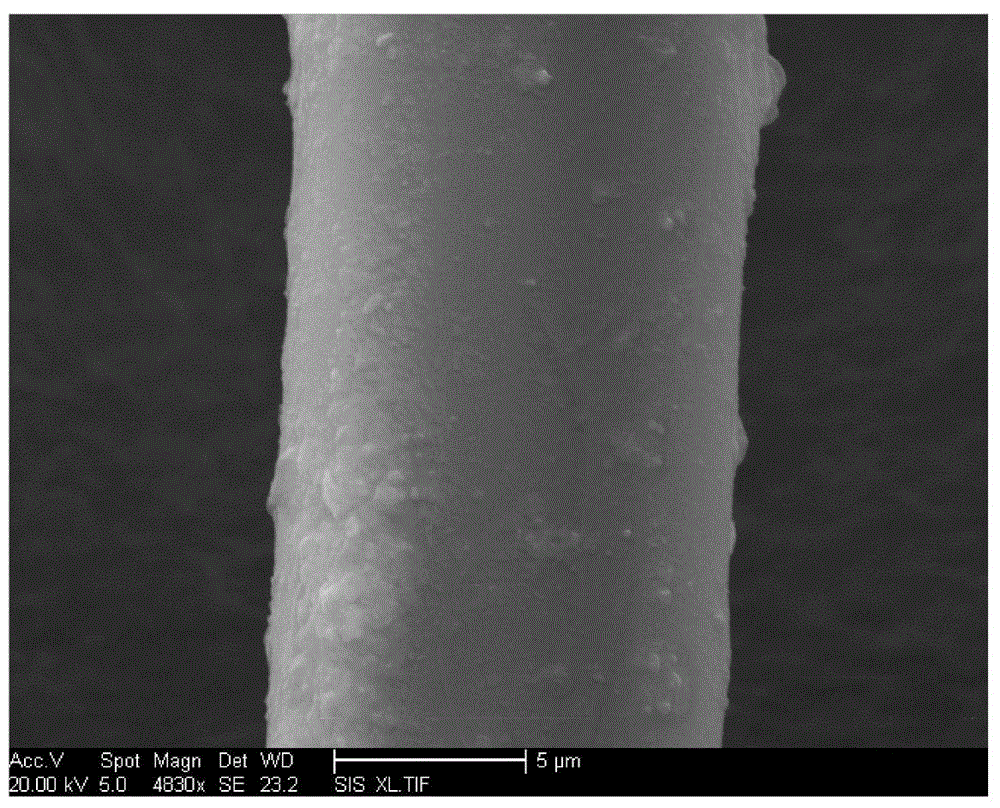

[0014] Embodiment 1: In this embodiment, a method for improving the anti-ultraviolet performance of M5 fiber by tubular titanium dioxide is carried out through the following steps:

[0015] 1. M5 fiber pretreatment: add KH-550 to the three-necked bottle, add deionized water drop by drop within 30 minutes, adjust the pH value to 2-5, put the M5 fiber into the solution, and keep the temperature at 45°C-55°C Take it out after reacting for 3h-4h under certain conditions, and place it at room temperature for 12h-24h to obtain the pretreated M5 fiber; the mass ratio of KH-550 to deionized water is 1:(0.4-0.5)

[0016] 2. Preparation of tubular titanium dioxide: dissolve anatase titanium dioxide in a NaOH solution with a concentration of 1mol / L-2mol / L, stir in an oil bath environment with a temperature of 120°C-140°C for 24h-36h, and then use a concentration of wash repeatedly with 0.1mol / L-0.5mol / L hydrochloric acid and distilled water, adjust the pH value to 7, and finally dry in a...

specific Embodiment approach 2

[0021] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the mass ratio of KH-550 to deionized water in step 1 is 5:1. Others are the same as the first embodiment.

specific Embodiment approach 3

[0022] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the pH value is adjusted to 4 in step 1. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com