Fabric resistance sensor and preparation method thereof

A resistance sensor and fabric technology, which is applied in the direction of transmission of sensing components, physical processing, textiles and papermaking using electric/magnetic devices, and can solve the problems of poor weaving performance, poor wearing comfort, and difficulty in spinning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

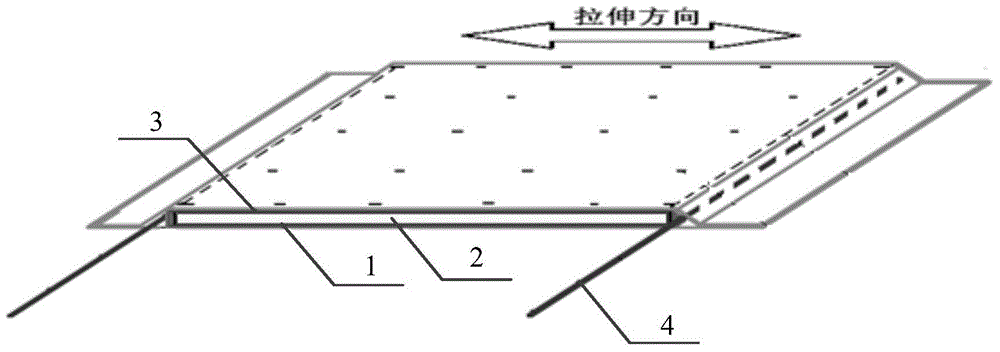

[0027] A fabric resistance sensor provided by the present invention, the structure of the fabric resistance sensor is divided into three layers from top to bottom, which are the first layer of fabric 1, the second layer of fabric 2 and the third layer of fabric 3, the second layer of fabric Layer fabric 2 contains polyaniline composite conductive yarns.

[0028] The preparation of the polyaniline composite conductive yarn has the following steps:

[0029] Yarn pretreatment: The yarn is pretreated with atmospheric pressure plasma to increase its surface roughness and surface adsorption performance, so as to improve the thickness and continuity of the polyaniline conductive layer and increase the conductivity of the yarn , and enhance t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com