Low noise micro-cantilever beam thermal vibration signal measuring device

A micro-cantilever beam and signal measurement technology, applied in the field of optical measurement, can solve problems such as noise and large mechanical vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

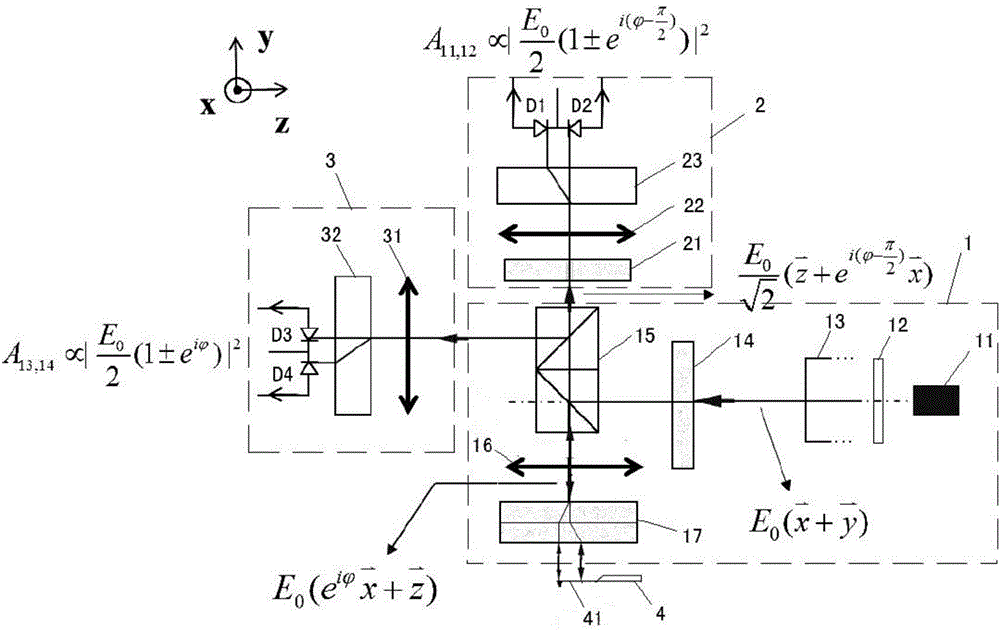

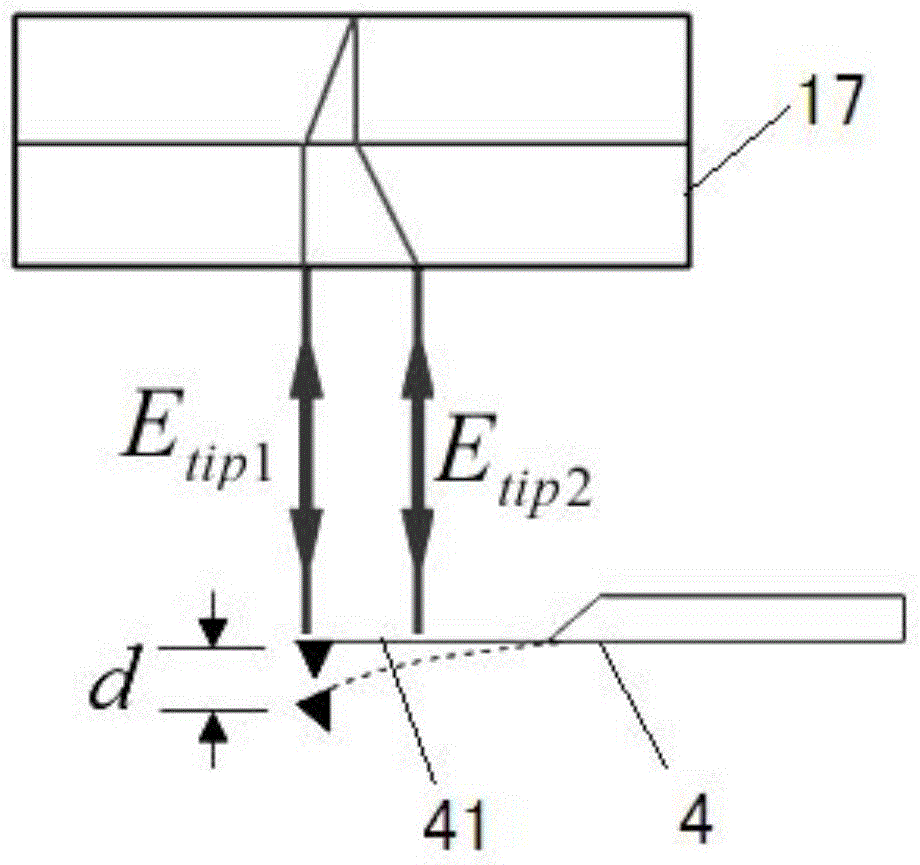

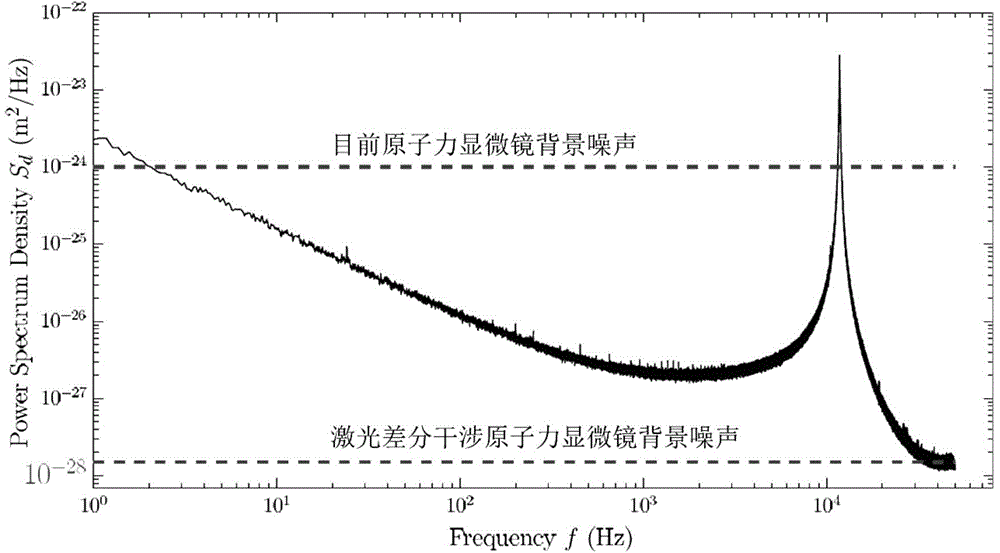

[0027] Such as Figure 1-2 As shown, a low-noise micro-cantilever thermal vibration signal measurement device includes a light incident component 1, a first interference arm optical path detection component 2 and a second interference arm optical path detection component 3, wherein the light incident component includes a laser 11 , a polarizer 12, a Glan Taylor prism 13, a first glass slide 14, a spherical beam splitter group 15, a first converging lens 16 and a bicite beam shifter 17 arranged in sequence on the propagation direction of the optical path of the laser 11, and the microcantilever The beam 4 is placed on the focal plane of the first converging lens 16. In this embodiment, the laser 11 is a He-Ne laser with a wavelength of 630nm. The device 12 polarizes into polarized light. The first slide 14 is a half slide, and the first slide 14 is mainly used to adjust the relative light intensity of the two beams of polarized light incident to the micro-cantilever beam 4; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com