Non-destructive detection method for martensite change amount in austenite stainless steel

A technology of austenitic stainless steel and martensitic transformation, applied in the direction of material magnetic variables, etc., can solve problems such as restricting the use of materials, and achieve the effects of easy portability, convenient and fast reading, and saving measurement costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments.

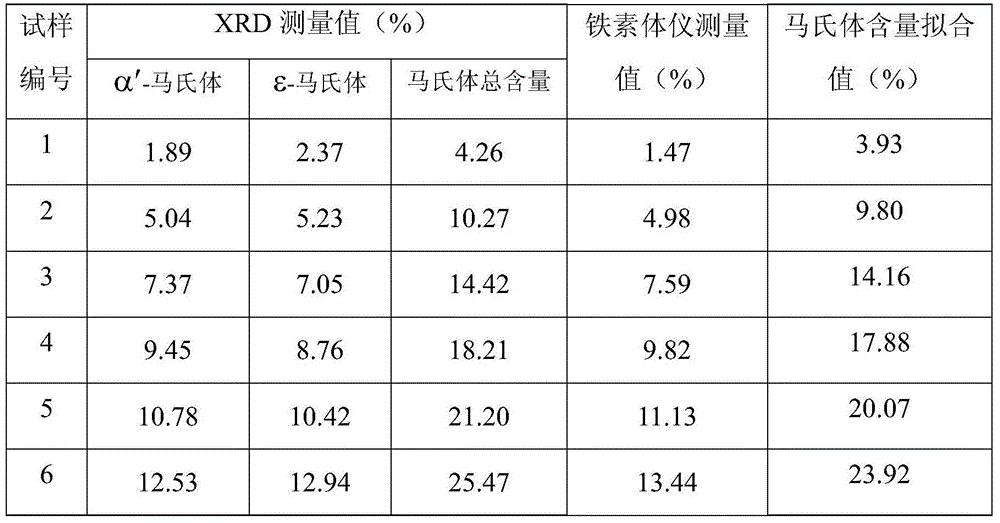

[0021] Since both deformation and low temperature environment will induce martensitic transformation, both of these inducements are considered in the detection method. The invention can be applied to austenitic stainless steel materials whose temperature can be as low as -269°C of liquid helium temperature and whose deformation amount is less than 15% in actual application process for non-destructive rapid detection.

[0022] ①Measure the content of ferromagnetic α'-martensite in austenitic stainless steel with a ferrite meter, and the value is recorded as x;

[0023] ②Then, the martensite transformation variable in austenitic stainless steel is calculated through the following functional relationship:

[0024] f(x)=1.67x+1.48;

[0025] In the above formula:

[0026] f(x) i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com