an omnidirectional 0 Modal lamb wave electromagnetic acoustic sensor

A sensor and electromagnetic acoustic technology, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, instruments, etc. To be improved and other issues, to achieve the effect of improving performance, realizing non-contact detection, and uniform magnetic field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and examples, and the following examples are only descriptive and not restrictive, and cannot be used to limit the protection scope of the present invention.

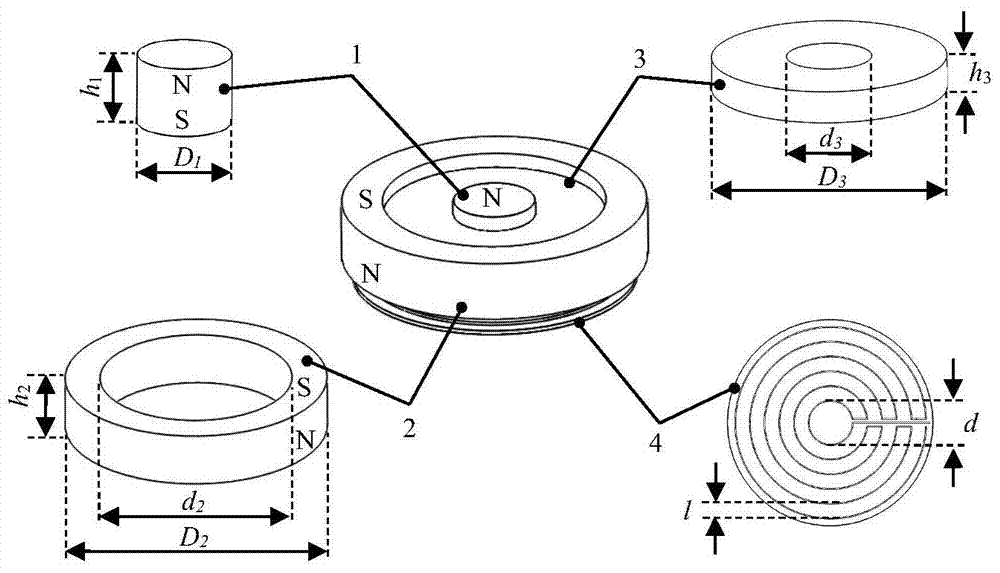

[0027] Such as figure 1 , is the omnidirectional type A of the present invention 0 Schematic diagram of the structure of the modal Lamb wave electromagnetic acoustic sensor; including a cylindrical NdFeB magnet 1, a ring-shaped NdFeB magnet 2, a support sleeve 3, and a double-layer helical folded coil 4. Cylindrical NdFeB magnet 1 and ring-shaped NdFeB magnet 2 form a concentric pair of magnets, and the polarities at the same end are opposite, which can generate a static magnetic field uniformly distributed along the radial direction of the magnet. The double-layer helical folded coil 4 is placed at the bottom end of the pair of concentric magnets and is in close contact with it.

[0028] The cylindrical NdFeB ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com