Omnidirectional horizontal shearing modal magnetostrictive sensor

A horizontal shearing and magnetostrictive technology, applied in the directions of ultrasonic/sonic/infrasonic waves, etc., can solve the problems of poor detection repeatability, high requirements for nickel sheet bonding, and difficulty in winding sensor coils. Signal-to-noise ratio, neatly arranged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with drawings and embodiments.

[0032] Based on the magnetostrictive effect, an omnidirectional horizontal shear mode magnetostrictive sensor is designed, and the sensor is used to excite a single-mode circumferentially consistent SH on the aluminum plate. 0 modal.

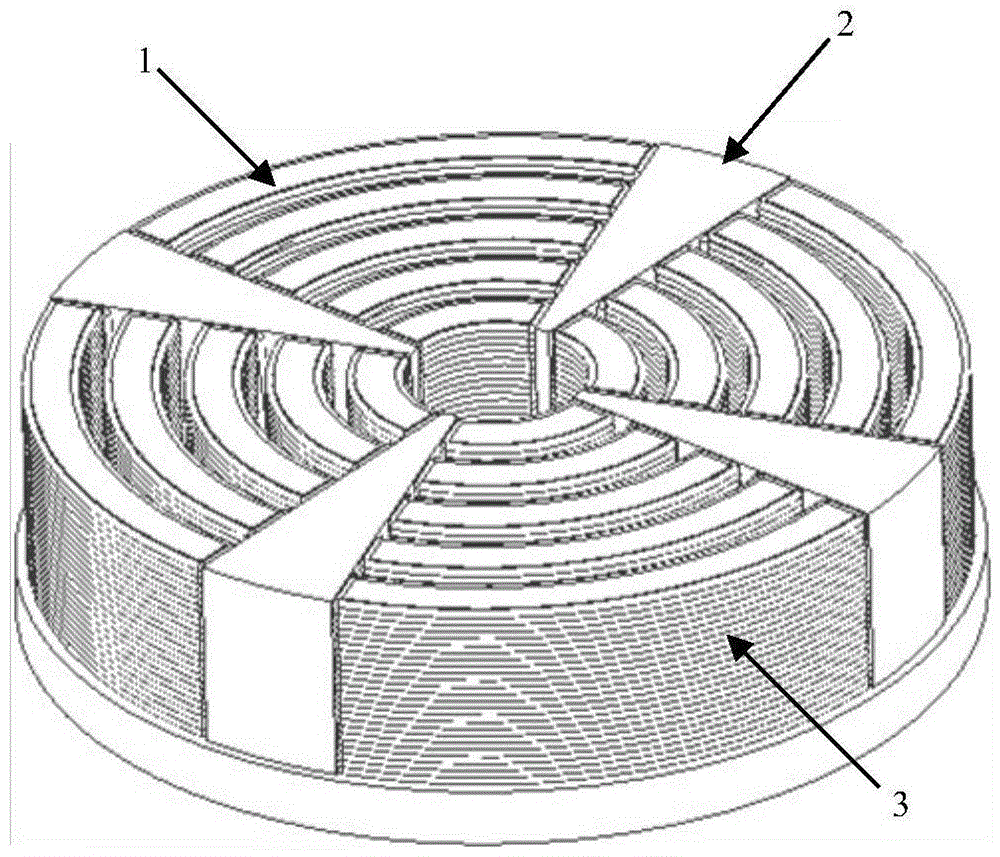

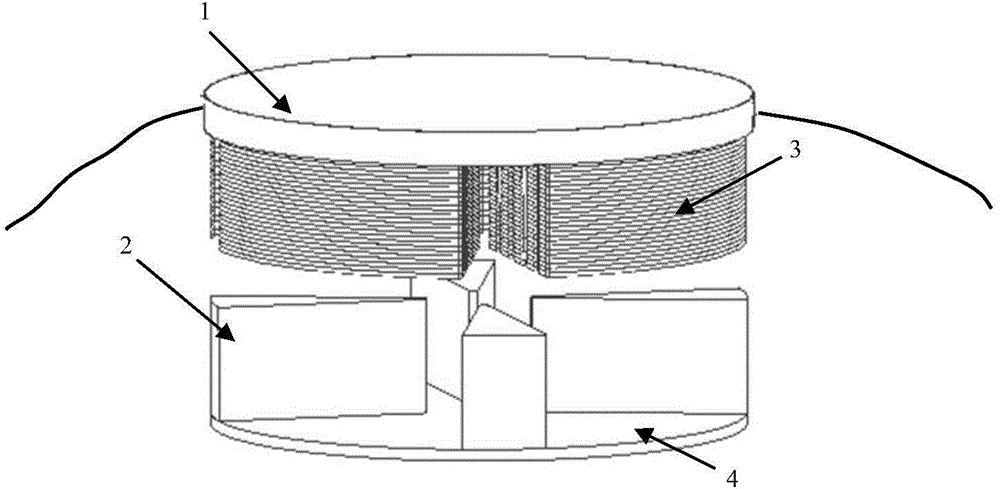

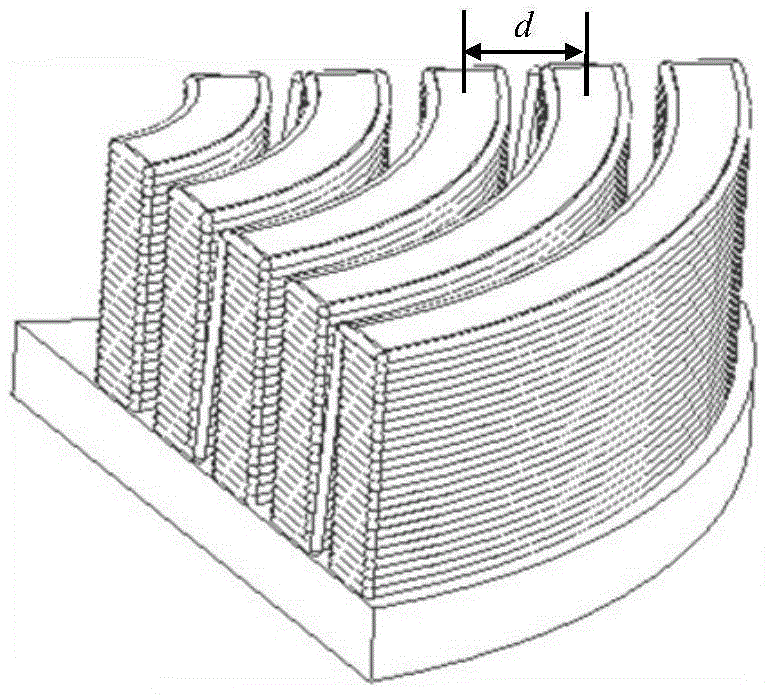

[0033] The structure diagram and decomposition diagram of the omnidirectional horizontal shear mode magnetostrictive sensor are as follows: figure 1 , 2 As shown, it includes a sensor housing 1, a NdFeB magnet 2, a spiral coil 3, and a circular nickel sheet 4. The detection object is an aluminum plate with a specification of 1000×1000×1 (unit: mm). Figure 5 are the dispersion curves of group velocity and phase velocity of the aluminum plate above. Use epoxy glue to bond the circular nickel sheet 4 on the surface of the aluminum plate, arrange the four fan-shaped NdFeB magnets 2 evenly in the circumferential direction on the circular ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com