Casting riser induction heating device and casting riser induction heating method

A technology of induction heating and induction heating power supply, which is applied in casting molding equipment, casting molds, casting mold components, etc. Efficiency and casting process export rate, the effect of improving casting process export rate and feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0036] The specific embodiment: the present invention will be further described below in conjunction with embodiment and experimental method:

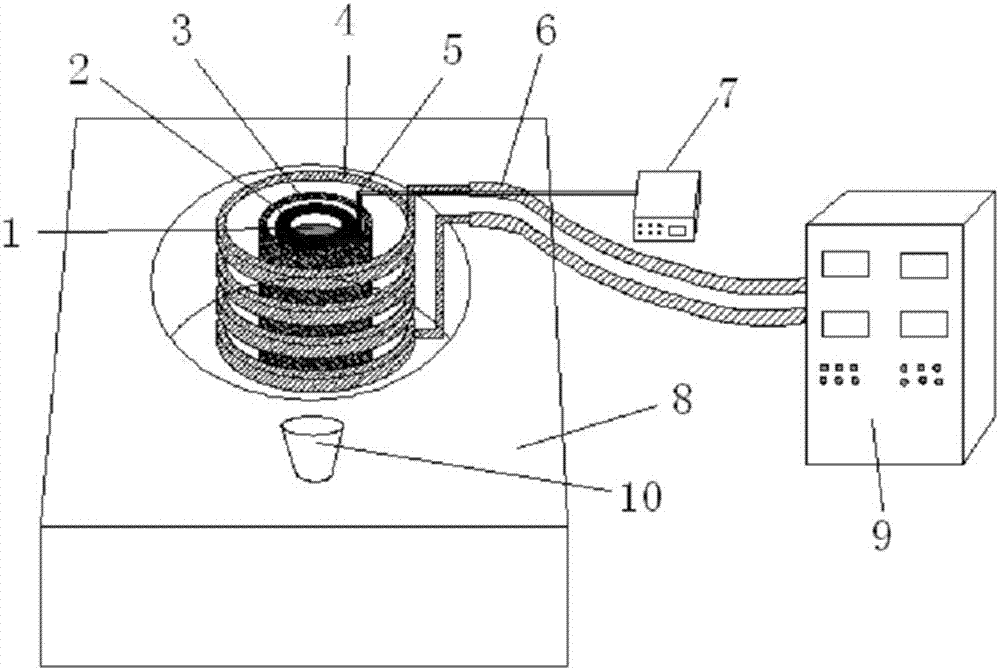

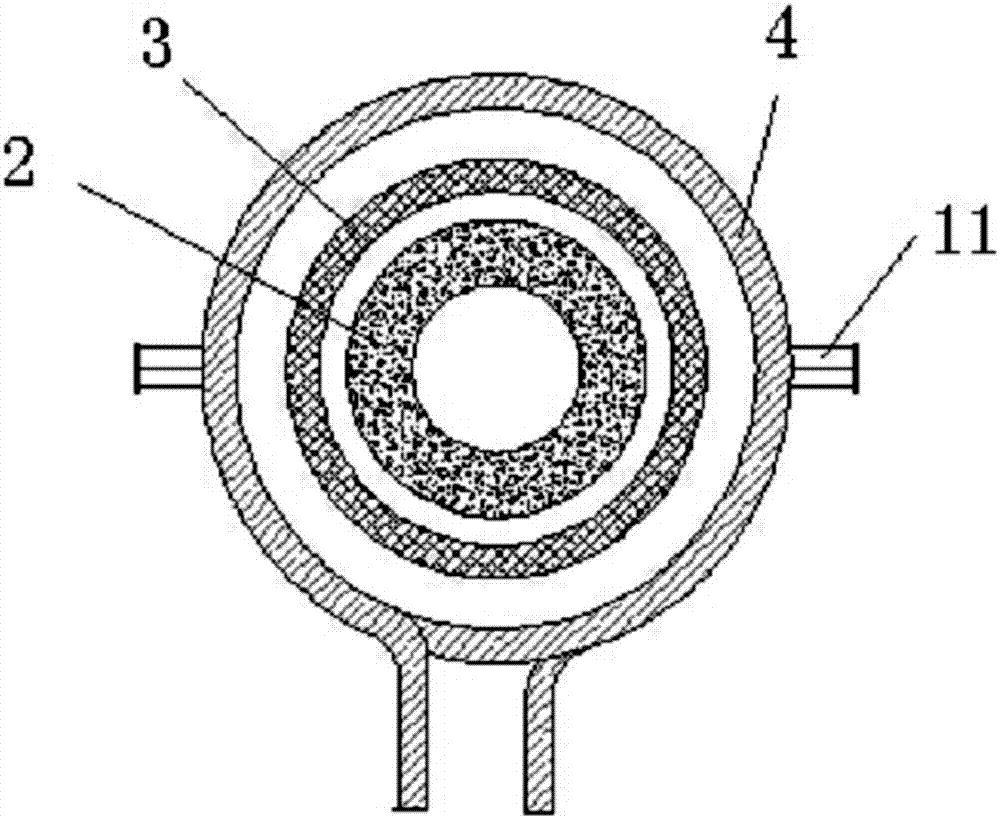

[0037] The present invention is an induction heating device for a casting riser, which comprises a riser sleeve 2, a graphite sleeve, a steel sleeve or a ring sleeve 3 made of other conductive materials, an induction coil 4, a thermocouple 5, a water-cooled cable 6, and a temperature recorder. instrument 7 and induction heating power supply box 9; ring sleeve 3 is arranged on the periphery of riser sleeve 2, induction coil 4 is arranged on the periphery of ring sleeve 3, and the two ends of induction coil 4 are connected with induction heating power supply box 9 through water-cooled cable 6, The temperature recorder 7 is connected to the thermocouple 5, and the thermocouple 5 is in contact with the inner wall of the riser sleeve 2.

[0038] In the casting riser induction heating method implemented by the above-mentioned casting riser i...

PUM

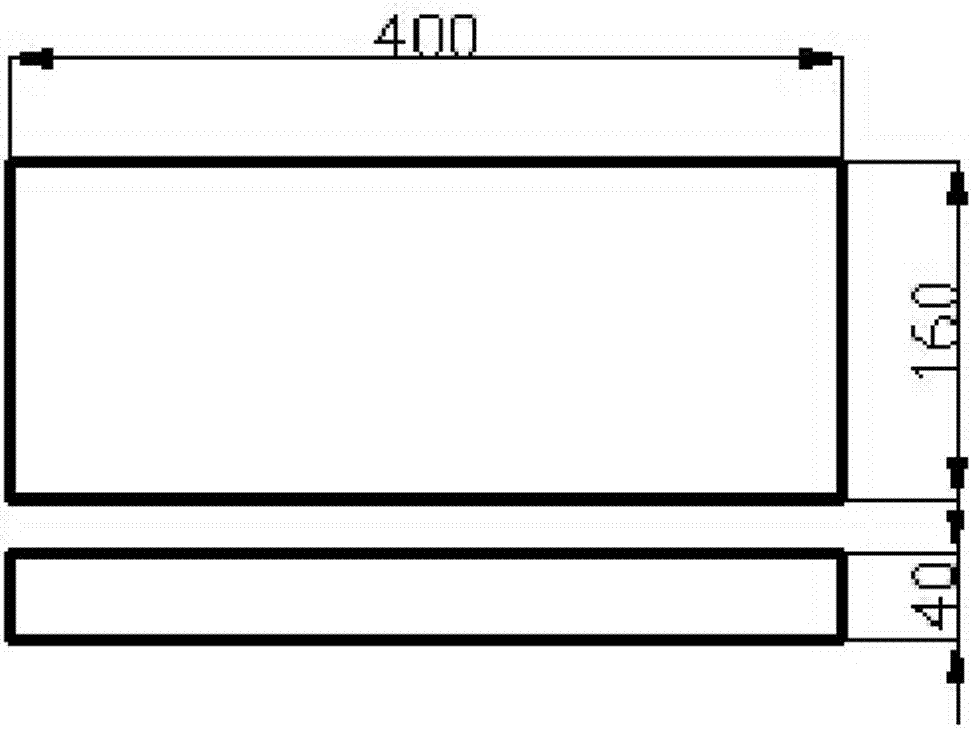

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com