Zirconia-zirconium boride double-layer composite ceramic heating element and preparation method thereof

A ceramic heating element and double-layer composite technology, which is applied in the field of electric heating materials, can solve the problems of poor oxidation resistance and achieve the effect of overcoming the double heating system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

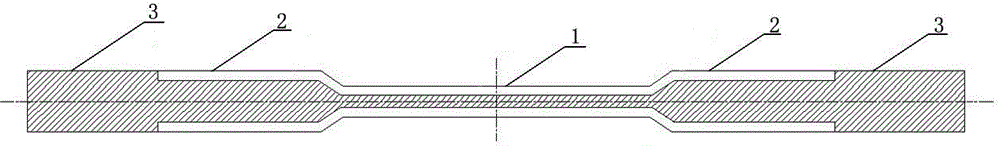

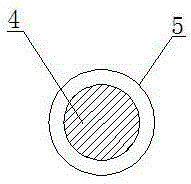

[0031] A zirconia-zirconium boride double-layer composite ceramic heating element, the heating element is composed of a heating section, two transition sections and two wiring sections, characterized in that: the heating section and the transition section are made of two layers of ceramics inside and outside Structural composition, the inner layer is ZrB with solid core structure 2 Matrix composite ceramics, the outer layer is ZrO 2 Matrix composite ceramics;

[0032] The preparation method of the zirconia-zirconium boride double-layer composite ceramic heating element comprises the following steps:

[0033] Step 1, take and prepare outer layer ZrO according to mass percentage 2 The raw materials of matrix composite ceramics were added to a vibrating mill, finely ground for 8 hours, then dried at 110°C for 4 hours, and passed through a 30-mesh sieve after drying to obtain ZrO 2 Composite powder, standby; then according to every hectogram ZrO 2 Add the mixed wax at a ratio ...

Embodiment 2

[0038] A zirconia-zirconium boride double-layer composite ceramic heating element, the heating element is composed of a heating section, two transition sections and two wiring sections, characterized in that: the heating section and the transition section are made of two layers of ceramics inside and outside Structural composition, the inner layer is ZrB with solid core structure 2 Matrix composite ceramics, the outer layer is ZrO 2 Matrix composite ceramics;

[0039] The preparation method of the zirconia-zirconium boride double-layer composite ceramic heating element comprises the following steps:

[0040] Step 1, take and prepare outer layer ZrO according to mass percentage 2 The raw materials of matrix composite ceramics are added to a vibrating mill, finely ground for 20 hours, then dried at 150°C for 10 hours, and passed through a 80-mesh sieve after drying to obtain ZrO 2 Composite powder, standby; then according to every hectogram ZrO 2 Add the mixed wax in the pro...

Embodiment 3

[0045] A zirconia-zirconium boride double-layer composite ceramic heating element, the heating element is composed of a heating section, two transition sections and two wiring sections, characterized in that: the heating section and the transition section are made of two layers of ceramics inside and outside Structural composition, the inner layer is ZrB with solid core structure 2 Matrix composite ceramics, the outer layer is ZrO 2 Matrix composite ceramics;

[0046] The preparation method of the zirconia-zirconium boride double-layer composite ceramic heating element comprises the following steps:

[0047] Step 1, take and prepare outer layer ZrO according to mass percentage 2 The raw materials of matrix composite ceramics were added to a vibrating mill, finely ground for 14 hours, then dried at 130°C for 7 hours, and passed through a 60-mesh sieve after drying to obtain ZrO 2 Composite powder, standby; then according to every hectogram ZrO 2 Add the mixed wax at a ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com