Method for producing 2-chloro-3-cyanopyridine through continuous reaction

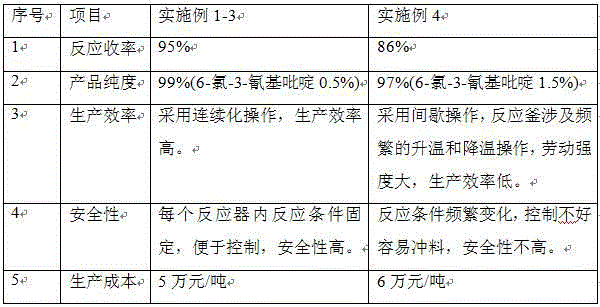

A technology for cyanopyridine and cyanopyridine nitrogen oxide, which is applied in the production field of 2-chloro-3-cyanopyridine, can solve the problems of unsolvable production efficiency, low reaction condition control and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

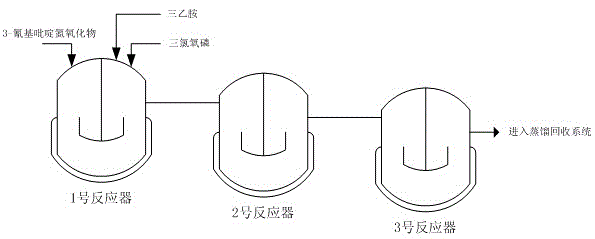

[0014] The weight ratio of 3-cyanopyridine nitrogen oxide, phosphorus oxychloride and triethylamine is 1:5:0.8, and the ratio of 1:5:0.8 is continuously added to the No. 1 reactor, and the temperature in the reactor is maintained at 20°C by controlling the feed rate. ~25°C; the reaction solution enters the No. 2 and No. 3 reactors from the No. 1 reactor in turn, and the temperature of the No. 2 kettle is controlled at 40~50°C, and the temperature of the No. 3 kettle is controlled at 80~90°C. The average residence time of the reaction solution in the No. 3 kettle The time is controlled within 1 to 2 hours, and the reaction liquid in the No. 3 kettle continuously enters the subsequent distillation recovery system.

[0015] The above reaction solution is distilled under reduced pressure to recover phosphorus oxychloride, the vacuum at the end of recovery is -0.06~-0.09MPa, the temperature is 85~105°C, and there is no obvious distillation of phosphorus oxychloride.

[0016] The co...

Embodiment 2

[0018] The weight ratio of 3-cyanopyridine nitrogen oxide, phosphorus oxychloride and triethylamine is 1:5:0.8, and the ratio of 1:5:0.8 is continuously added to the No. 1 reactor, and the temperature in the reactor is maintained at 20°C by controlling the feed rate. ~25°C; the reaction liquid enters the No. 2 reactor from the No. 1 reactor, and the temperature of the No. 2 pot is controlled at 80~90°C. The liquid continuously enters the subsequent distillation recovery system.

[0019] The above reaction solution is distilled under reduced pressure to recover phosphorus oxychloride, the vacuum at the end of recovery is -0.06~-0.09MPa, the temperature is 85~105°C, and there is no obvious distillation of phosphorus oxychloride.

[0020] The concentrated solution after recovery of phosphorus oxychloride is slowly put into 10 times of water to precipitate 2-chloro-3-cyanopyridine, control the discharge temperature not higher than 50°C, cool down to below 40°C after discharge and ...

Embodiment 3

[0022] 3-cyanopyridine nitrogen oxide and phosphorus oxychloride are continuously added to No. 1 reactor at a ratio of 1:5 by weight; the reaction solution overflows from No. 1 reactor and enters No. The weight ratio of pyridine nitrogen oxide and triethylamine is 1:0.8, and triethylamine is continuously added to No. 2 reactor, and the reaction temperature is controlled at 20 ° C ~ 25 ° C; the reaction liquid enters No. 3 reaction tank from No. 2 reactor The temperature of the No. 3 kettle is controlled at 80-90°C. The average residence time of the reaction solution in the No. 3 kettle is controlled at 1-2 hours. The reaction solution in the No. 3 kettle continuously enters the subsequent distillation recovery system.

[0023] The above reaction solution is distilled under reduced pressure to recover phosphorus oxychloride, the vacuum at the end of recovery is -0.06~-0.09MPa, the temperature is 85~105°C, and there is no obvious distillation of phosphorus oxychloride.

[0024] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com