Fluorine-containing acrylic acid super-hydrophobic resin for oil-water separation and preparation method thereof

A technology of oil-water separation and acrylic acid, which is applied in the direction of separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of insufficient hydrophobicity of the coating of the separation filter element, and achieve superior oil-water separation performance, excellent performance, and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

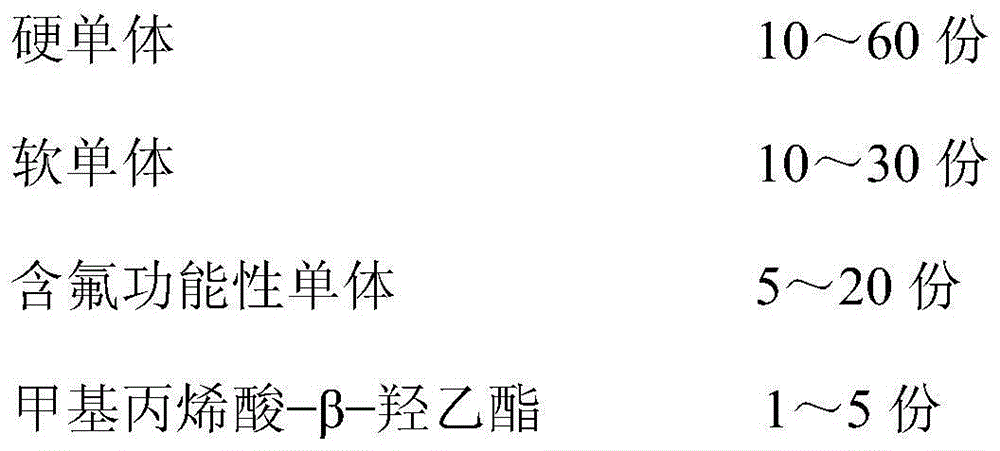

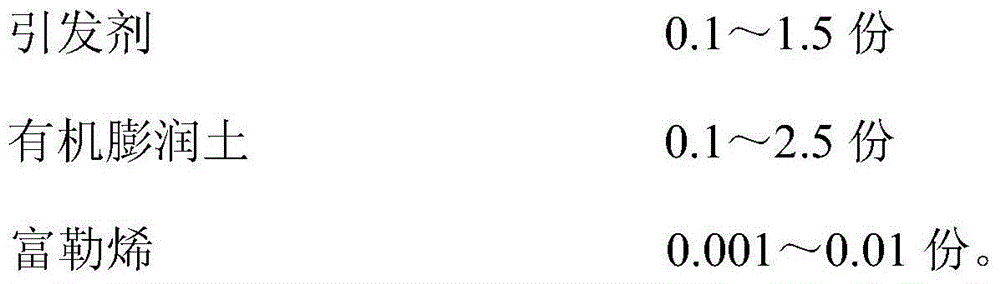

[0032] A fluorine-containing acrylic acid superhydrophobic resin for oil-water separation, prepared by solution radical polymerization in an organic solvent using the following raw materials in parts by weight:

[0033]

[0034] Concrete preparation steps are as follows:

[0035] a. Completely dissolve the hard monomer, soft monomer, fluorine-containing functional monomer, β-hydroxyethyl methacrylate and 2 / 3 of the initiator in 1 / 2 of the organic solvent, and control the mixed monomer The total mass concentration is 35%;

[0036] b. Add the remaining organic solvent into the reaction kettle, and put in the organic bentonite, and stir until the organic bentonite is completely dispersed to form a homogeneous system;

[0037] c. Raise the temperature of the reactor to 80°C, then slowly put in the solution a at a uniform speed, and control the time of putting it in for not less than 1 hour. After the feeding is completed, continue the heat preservation reaction for 1 hour, the...

Embodiment 2

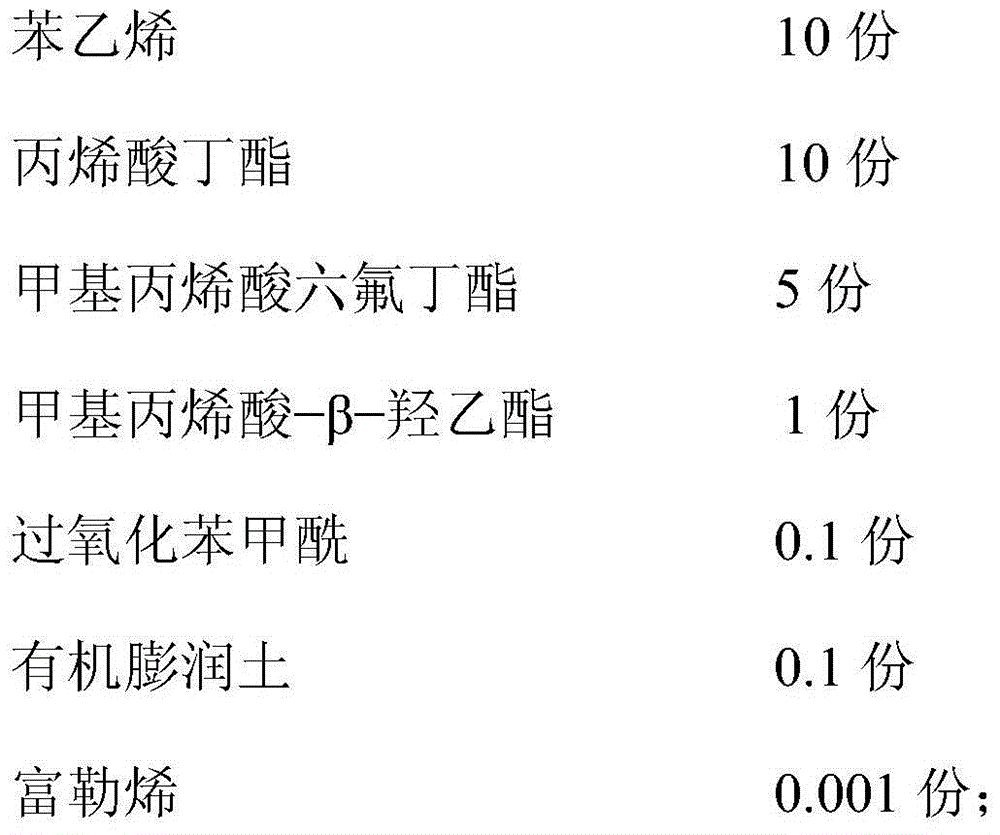

[0040] A fluorine-containing acrylic acid superhydrophobic resin for oil-water separation, prepared by solution radical polymerization in an organic solvent using the following raw materials in parts by weight:

[0041]

[0042] Concrete preparation steps are as follows:

[0043] a. Completely dissolve hard monomer, soft monomer, fluorine-containing functional monomer, β-hydroxyethyl methacrylate and 3 / 4 of the initiator in 3 / 4 of the organic solvent, and control the mixing of monomers The total mass concentration is 65%;

[0044] b. Add the remaining organic solvent into the reaction kettle, and put in the organic bentonite, and stir until the organic bentonite is completely dispersed to form a homogeneous system;

[0045] c. Raise the temperature of the reaction kettle to 90°C, then slowly put in the solution a at a uniform speed, and control the time of putting it in for not less than 1 hour. After the feeding is completed, continue the heat preservation reaction for 6 ...

Embodiment 3

[0048] A fluorine-containing acrylic acid superhydrophobic resin for oil-water separation, prepared by solution radical polymerization in an organic solvent using the following raw materials in parts by weight:

[0049]

[0050] Concrete preparation steps are as follows:

[0051] a. Fully dissolve the hard monomer, soft monomer, fluorine-containing functional monomer, β-hydroxyethyl methacrylate and 70% initiator in 60% organic solvent, and control the total mass of the mixed monomer The concentration is 40%;

[0052] b. Add the remaining organic solvent into the reaction kettle, and put in the organic bentonite, and stir until the organic bentonite is completely dispersed to form a homogeneous system;

[0053] c. Raise the temperature of the reaction kettle to 85°C, and then slowly add the solution a at a uniform speed, and control the input time for not less than 1 hour. After the feeding is completed, continue the heat preservation reaction for 3 hours, then add the rem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com