Liquid nitrogen cooling tower solar thermoelectric power station

A tower type solar energy and liquid nitrogen cooling technology, applied in the field of solar power generation, can solve the problems of insufficient temperature difference, low heat exchange efficiency, insufficient utilization efficiency of concentrated high-temperature heat energy, etc. The effect of utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

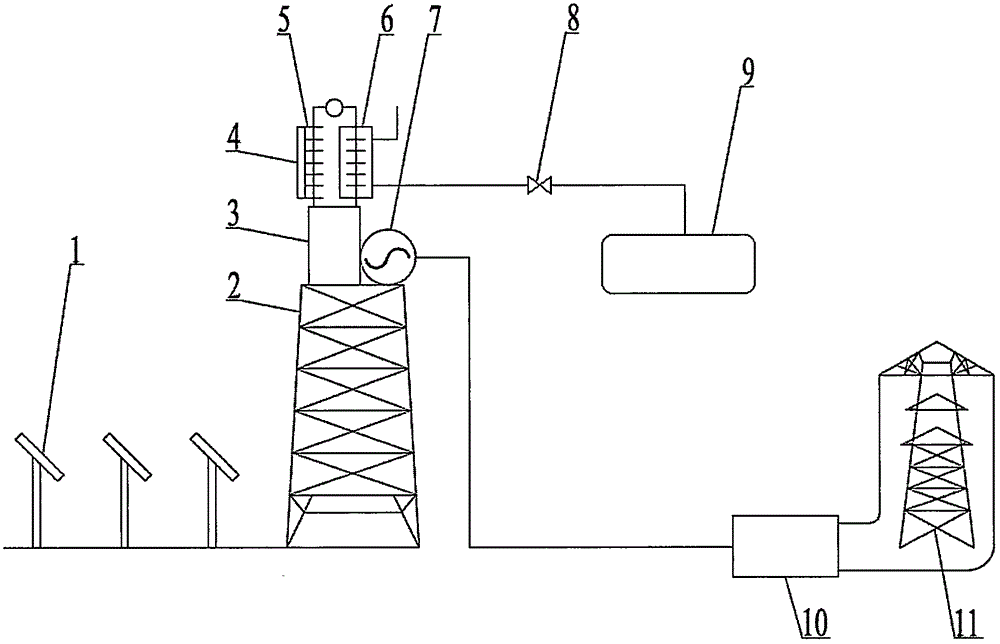

[0017] Embodiment one: see figure 1 , a liquid nitrogen cooling tower solar thermal power station, comprising a tower, a reflector field, a heat absorber, a generator, a thermoelectric engine, and a liquid nitrogen storage tank.

[0018] The cooler of the program-controlled switch-type thermoelectric engine is enclosed in a sealed box, and the box has at least one inlet for liquid nitrogen to enter, and at least one outlet for nitrogen to discharge.

[0019] As the cooling medium, liquid nitrogen flows out from the liquid nitrogen storage tank, enters the sealed box where the cooler of the thermoelectric engine is located in a liquid state, cools the cooler of the thermoelectric engine, and is vaporized into gas, which is discharged into the atmosphere from the outlet.

[0020] Between the liquid nitrogen storage tank and the sealed box where the cooler is located, a throttle valve is installed to adjust the flow of liquid nitrogen, and the throttle valve is controlled by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com