AT speed variable box large displacement rotor type internal meshing gear pump

An internal meshing gear pump with large displacement technology, applied in the field of transmission, can solve the problems of inability to meet modular design requirements, complex layout structure and size, and high processing accuracy requirements, and achieve light weight, compact structure size, and smooth operation. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

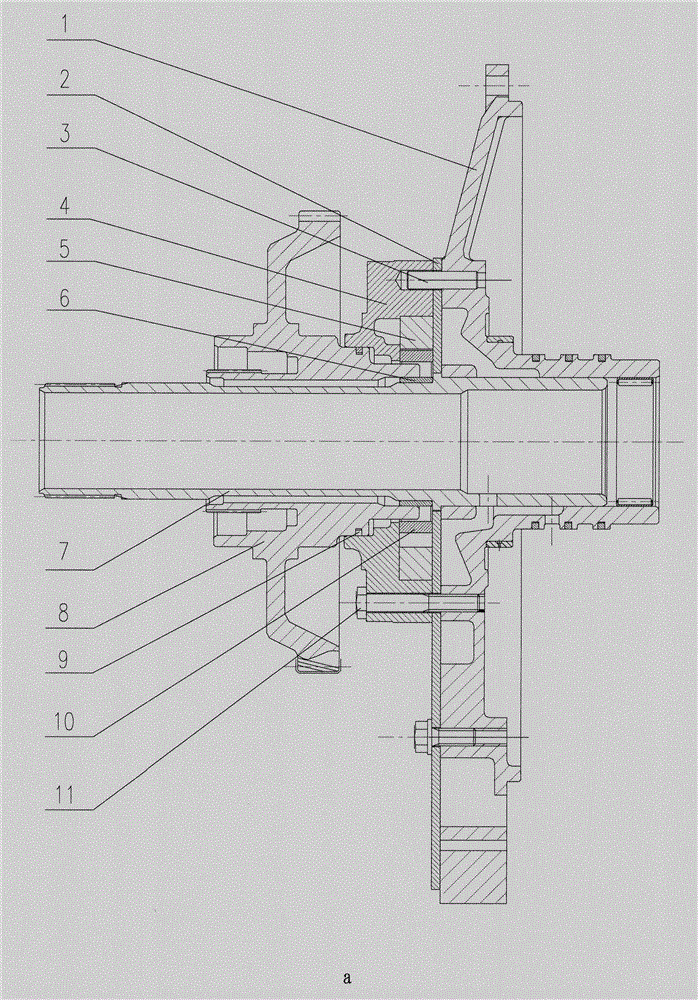

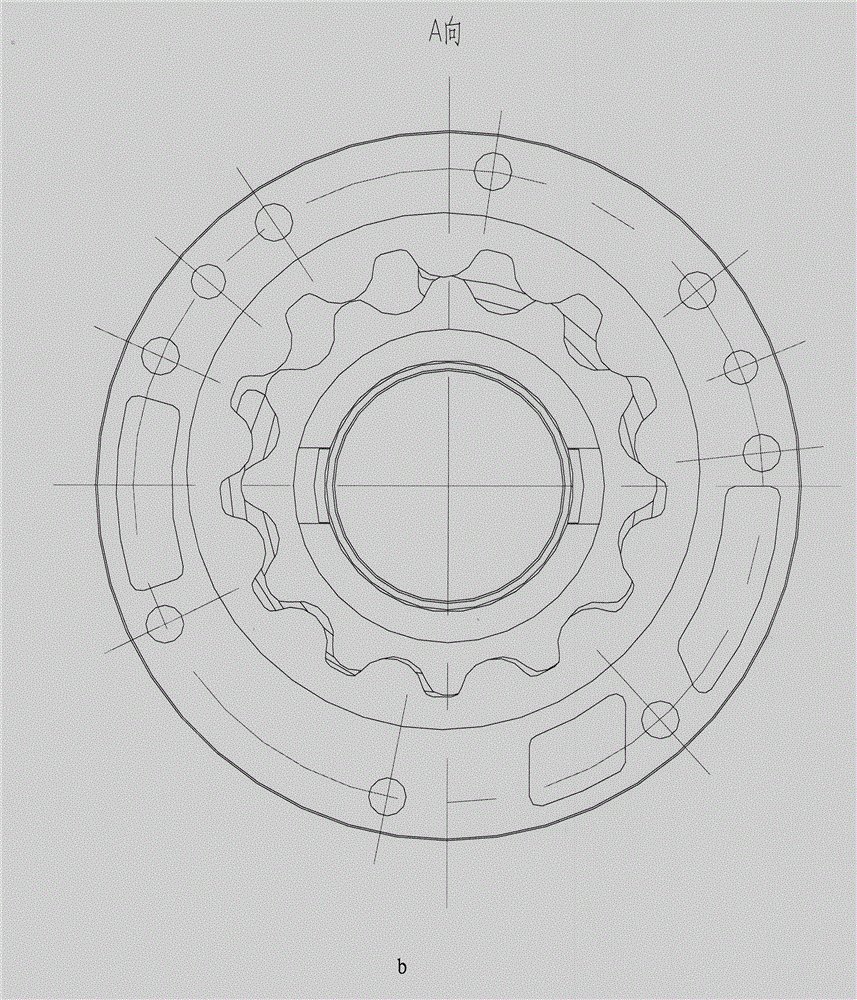

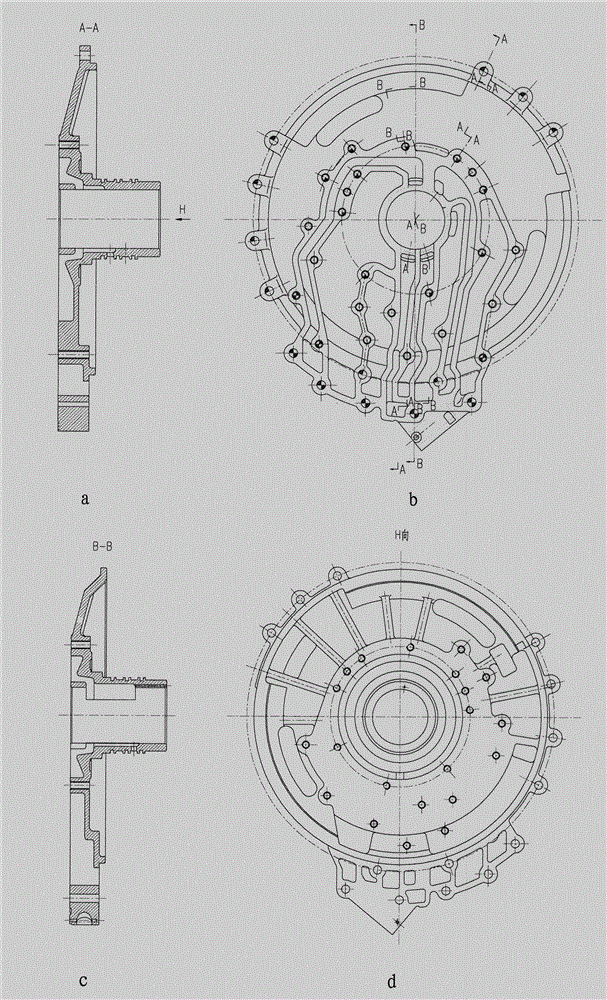

[0027] Such as Figure 1-11 As shown, the present invention is a large-displacement cycloidal rotor type internal gear pump with an AT gearbox with a hydraulic torque converter compensation oil passage, which is installed in the casing of the automatic transmission and passes through the outer spigot on the valve plate 1 Position with the inner hole of the transmission case, connect and fix with the transmission case with bolts. The specific structure is:

[0028] Including distribution plate 1, distribution plate 2, positioning pin 3, pump body 4, outer rotor 5, sliding bearing 6, connecting shaft 7, input shaft 8, sealing ring 9, inner rotor 10 and bolts 11.

[0029] The connecting shaft 7 is divided into left and right sections, and the joints of the left and right sections are raised shoulders. The outer circle at the right end of the connecting shaft 7 is pressed into the hole of the flow distribution plate 1, and the outer spline at the left end should be in contact wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com