Grouting sealing hole stop grout visual experimental device and experimental method thereof

An experimental device and hole sealing technology, which is applied in the direction of measuring device, earthwork drilling, sealing/isolation, etc., to achieve reliable data support and design support, simple operation and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

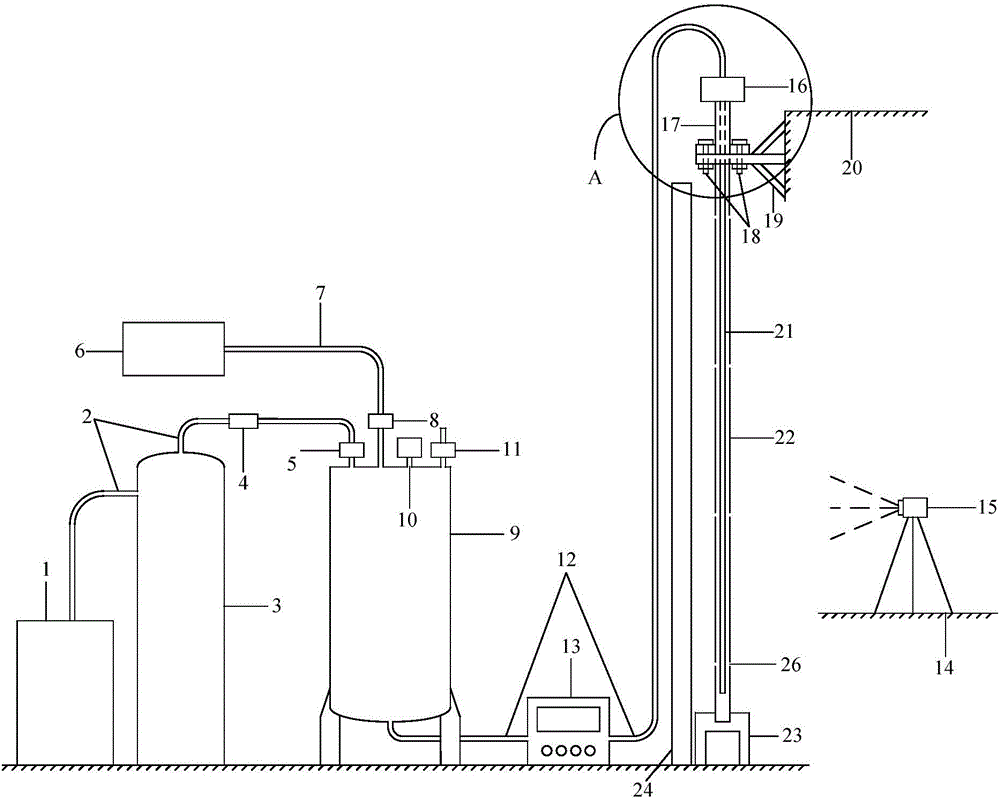

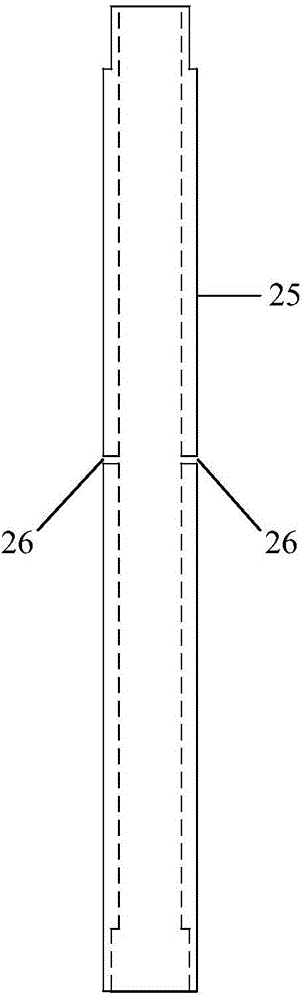

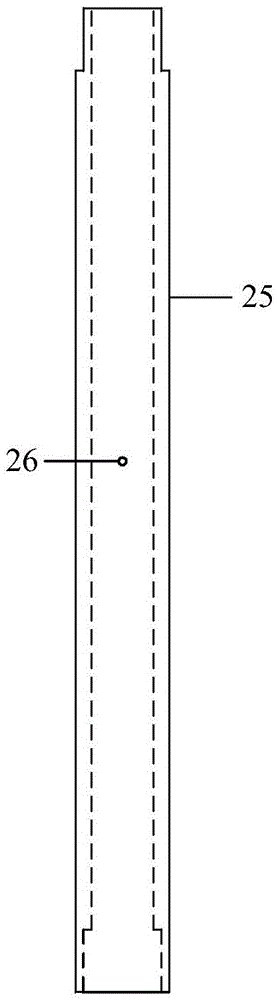

[0040] a kind of like Figure 1 to Figure 5 The grouting sealing and grouting visualization experimental device of the present invention is shown, the experimental device includes a pressure supply system, a grouting system, a monitoring system and a sealing and grouting visualization system; the pressure supplying system is connected to the grouting system, and the grouting system is connected to the sealing The grout stop visualization system, the pressure provided by the pressure supply system makes the grout in the grout supply system inject into the hole sealing and stop grout visualization system, and the monitoring system conducts high-definition monitoring of the grouting process of the aforementioned hole seal and stop grout visualization system.

[0041] Such as figure 1 As shown, the pressure supply system in this embodiment includes an air compressor 1, a vent hose 2, a high-pressure gas storage tank 3, a pressure regulating valve 4 and a first valve 5; wherein the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com