Logistics center dump intelligent decision control system based on RFID and batch flow technologies and method

A control system and intelligent decision-making technology, applied in the direction of logistics, collaborative operation devices, instruments, etc., can solve the problems of increasing the operating cost of the logistics center, increasing the work pressure of personnel, and limited decision-making time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The flow of the intelligent decision-making control method of logistics center dump based on RFID and batch flow technology of the present invention, the specific steps are as follows:

[0065] (1) Batch decomposition

[0066] Step 1. Obtain the dumped variety and quantity (or custom) in the time period from the loading batch, and set the variety i The demand is 8 million, and the variety i Traverse the existing inventory, set Bs to 15 days, then search for "variety i Batch time i {Variety, batch, quantity, storage location};

[0067] Step 2. If STB i The total amount did not reach this TR i , Which is 8 million, then take the quantity and location within the range of "Next Earliest Batch + Bs" and add it to the set STB i And repeat step 2, when the total amount reaches this TR i If the quantity is 8 million, then skip to step 1 and continue to take the next variety i +1, until all varieties in TR are traversed;

[0068] Step 3. Output STB {variety, batch, quantity, storage loca...

Embodiment 2

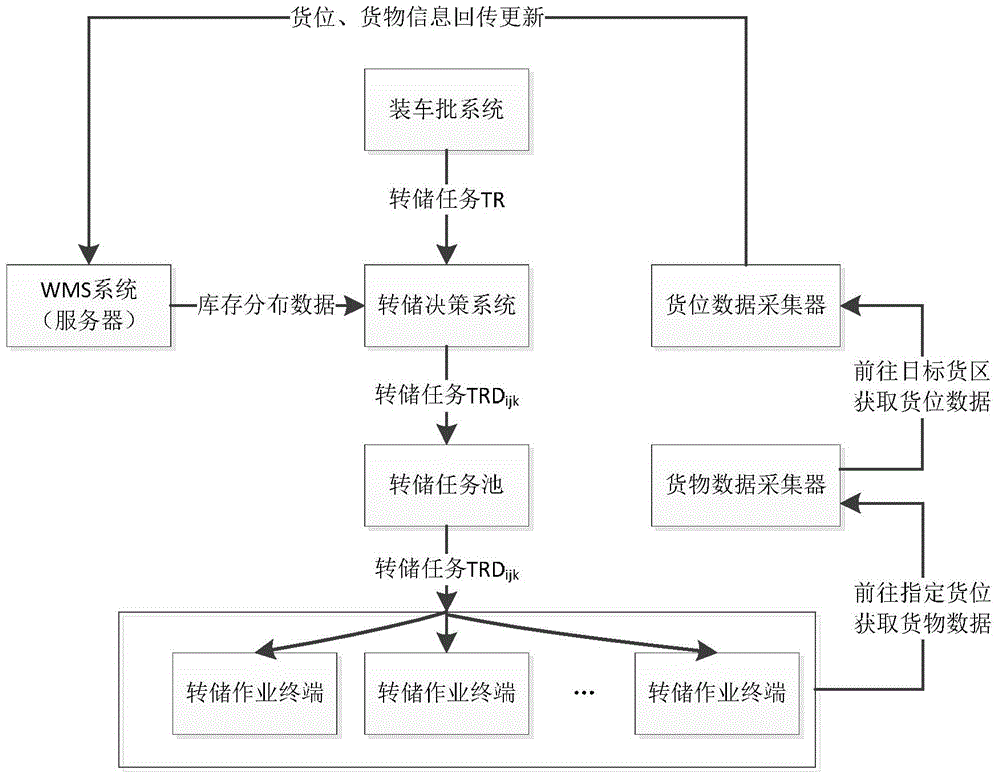

[0090] The present invention is a logistics center dump intelligent decision control architecture diagram based on RFID and batch flow technology (such as figure 1 ):

[0091] Step 1. The dump decision system imports dump tasks from the loading batch system, and imports inventory data from the WMS system;

[0092] Step 2. The dump batch TRD is generated by the dump decision system ijk For specific methods, refer to steps 1 to 19 of the batch decomposition and scheduling method based on batch streaming technology;

[0093] Step 3. All TRD ijk (Dump batch) sent to the dump task pool for standby;

[0094] Step 4. The dump task is allocated to each dump operation terminal from the task pool;

[0095] Step 5: The forklift operator drives to the designated pickup area according to the information obtained by the dump operation terminal;

[0096] Step 6. The forklift operator operates the dump operation terminal to fetch the designated goods;

[0097] Step 7, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com