Modeling optimization method for picking job scheduling in automated three-dimensional warehouse based on petri net and improved genetic algorithm

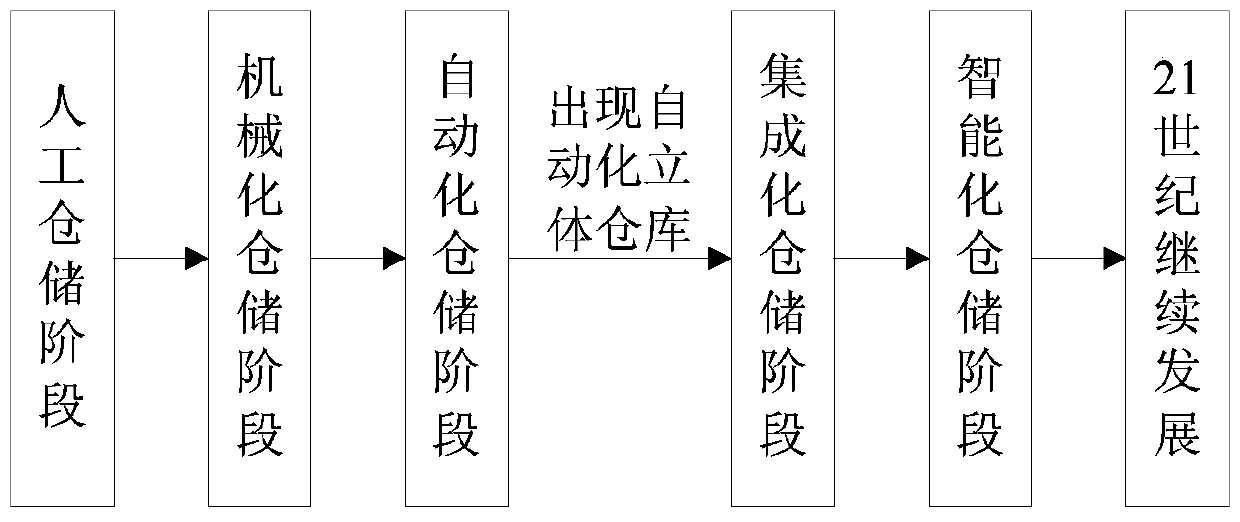

An improved genetic algorithm and job scheduling technology, applied in the field of optimization and analysis of automated three-dimensional warehouse job scheduling, can solve problems such as unreasonable scheduling of automated three-dimensional warehouse job scheduling, unmanned research on scheduling optimization, and reduced storage efficiency of automated three-dimensional warehouses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0103] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

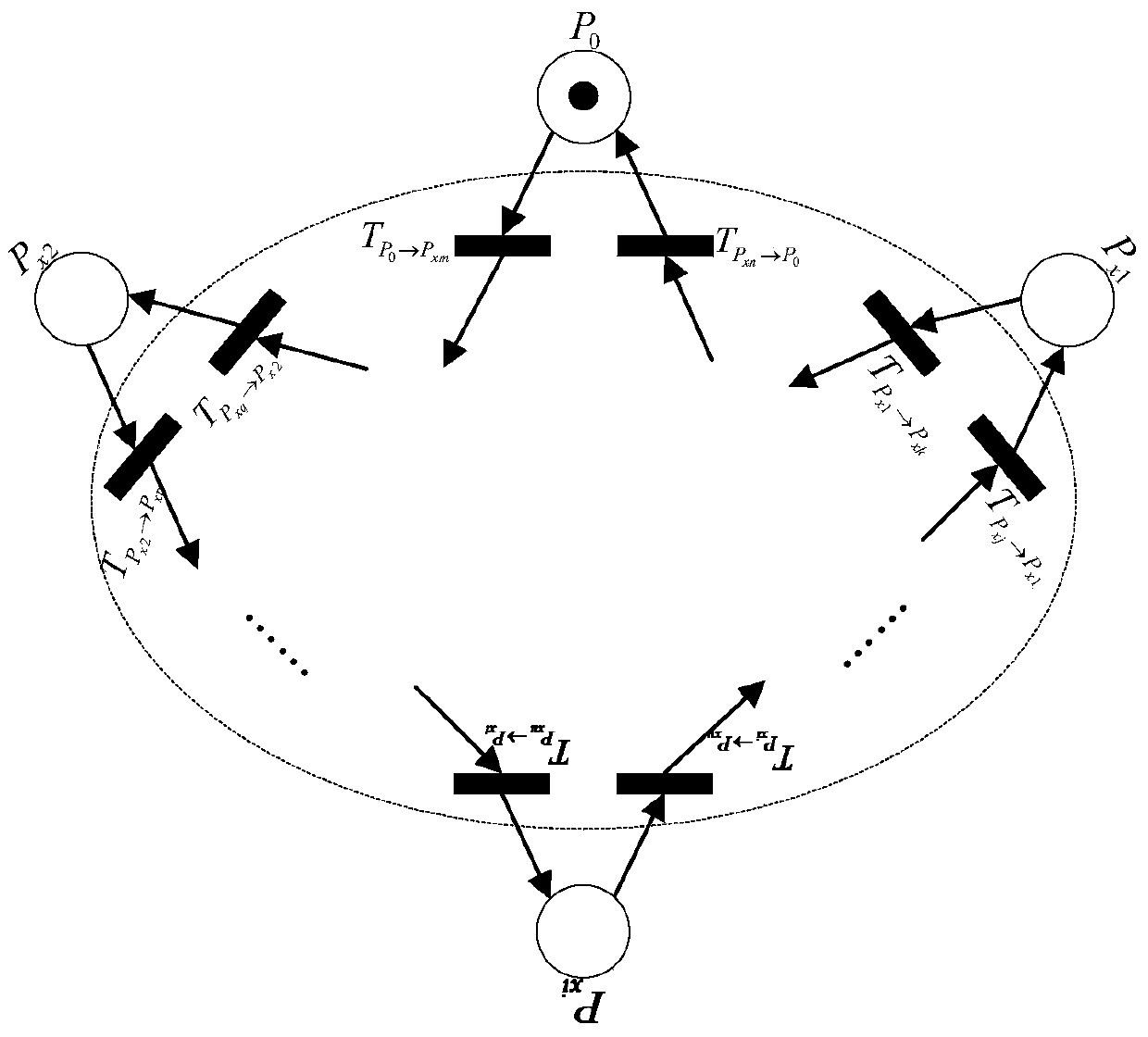

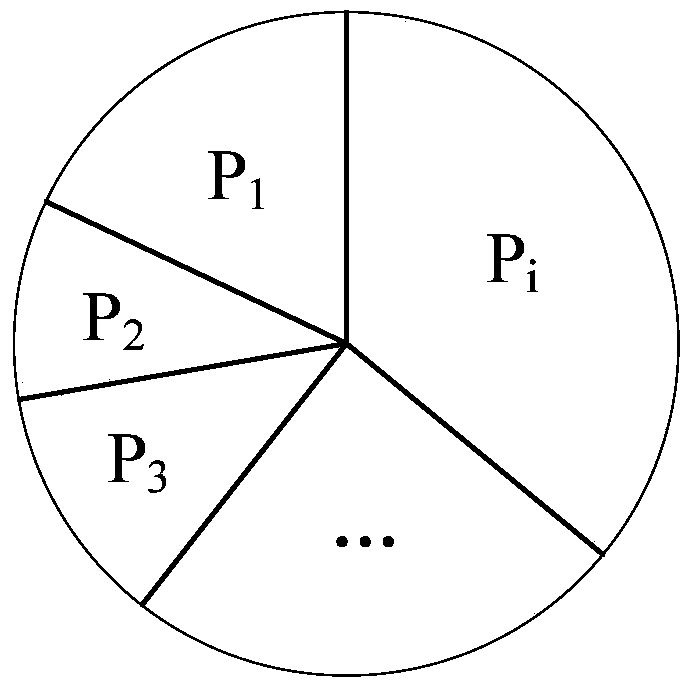

[0104] Figure 9 It is a schematic flow chart of the method of the present invention. As shown in the figure, the method includes the following steps: Step 1: Establish a Petri net model for picking operation scheduling in an automated three-dimensional warehouse, and propose a fixed part and a variable part time consumption for picking job scheduling optimization The mathematical expression of the picking job scheduling optimization problem is studied from the mathematical level; Step 2: Design a job scheduling optimization algorithm based on the combination of Petri net and improved genetic algorithm, combine Petri net with improved genetic algorithm, and design a reversal operator Improve the genetic algorithm to achieve high-quality and fast optimization of the job scheduling process; Step 3: Design an automated three-dimensional wareho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com