Ore blending method of strip mine production

A technology for open-pit mines and ore blending, which is applied in the fields of instruments, data processing applications, and calculations, and can solve problems such as unreasonable ore blending plan preparation, unreasonable ore supply grades, and impact on the status of production objects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] A method for producing ore in an open-pit mine, comprising the steps of:

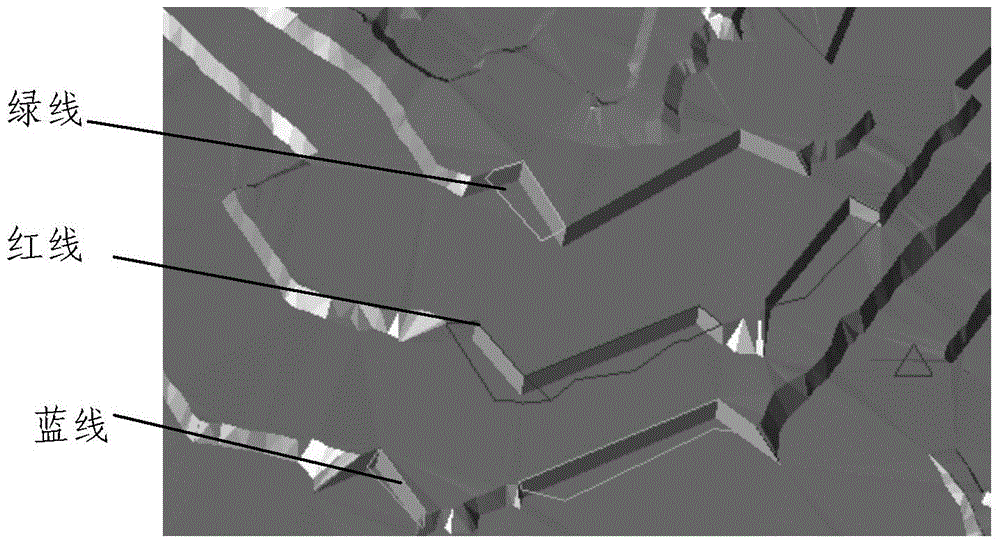

[0061] 1. Acquisition of explosion pile data: Obtain the scope of the explosion area, set up the blast hole, blast, obtain the blast hole database and rock powder data, and obtain figure 1 ;

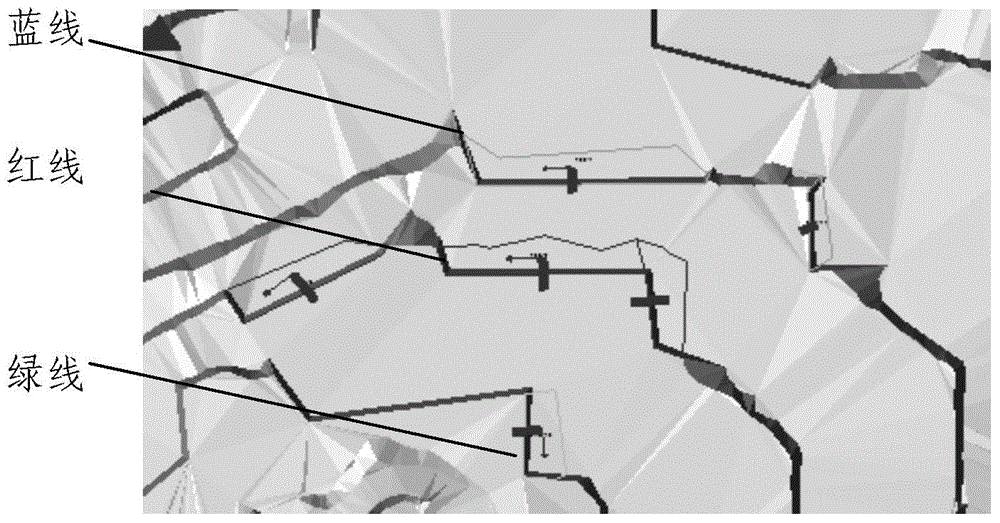

[0062] 2. Constraint information on initialization of blast area ( figure 2 ), the constraint information includes step height, main propulsion direction, possible mining direction, mining width, and the size of subdivided grid;

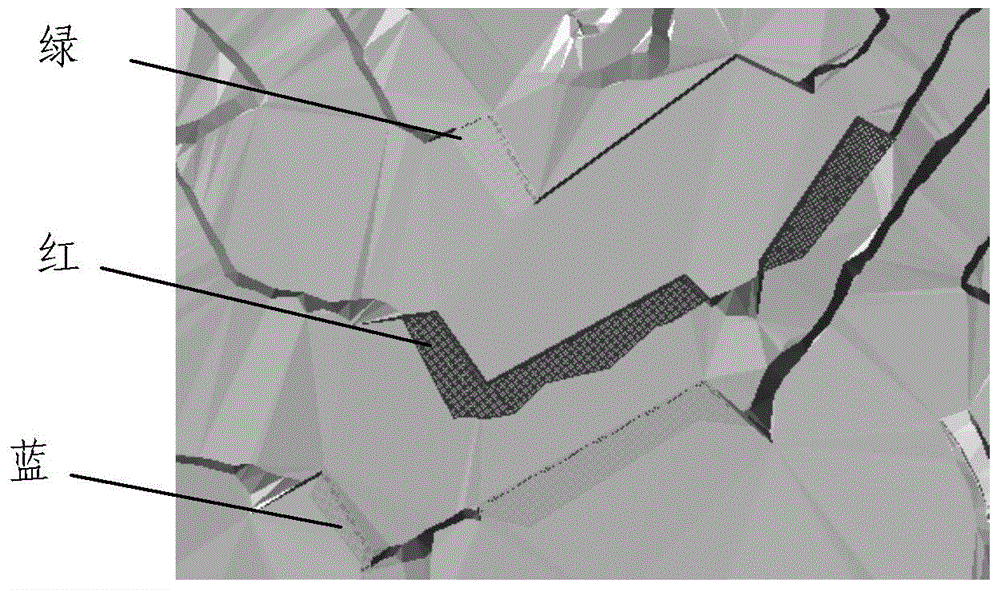

[0063] 3. Carry out grid division according to the information of the explosion area ( image 3 ), estimate each grid separately according to the blasthole database, and obtain the ore quantity and grade of each grid, so as to know the mineable quantity and grade distribution of the explosion area.

[0064] 4. Set the ore output and ore grade limits according to the demand, and set up constraints (see Table 1, the grade is Cu 0.2-0.3, Mo 0.01-0.015, the number of ore blending ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com