Electric vehicle battery plate

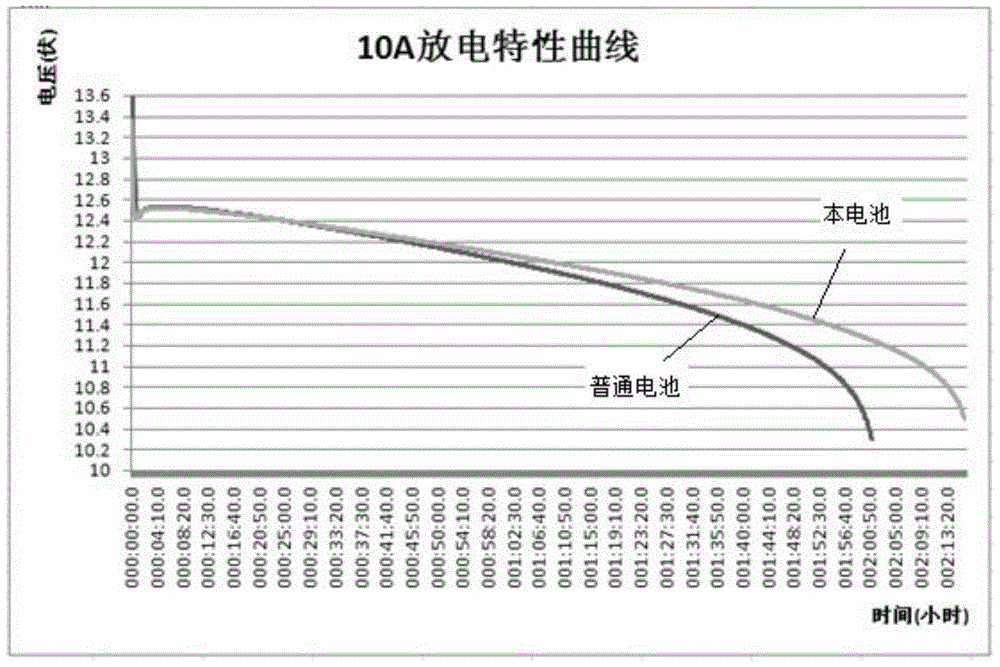

A technology for electric vehicle batteries and plates, applied to the electrodes of lead-acid batteries, etc., can solve problems such as limitations, and achieve the effect of increasing the electrochemical reaction area and improving the performance of high-current discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] An electric vehicle battery plate, including a positive plate and a negative plate, characterized in that: the external dimensions of the positive plate are 66.5mm wide; 143mm high; 2.06mm thick; its α value is 1:13; MS value is 3.5 g / cm 2 , which increases the electrochemical reaction area and improves the high-current discharge performance of the battery; the external dimensions of the negative plate are 66.5mm wide; 144mm high; 1.42mm thick; the α value is 1:11; the MS value is 2.3g / cm 2 , increasing the electrochemical reaction area and improving the high-current discharge performance of the battery. Among them, the α value represents the ratio of the mass of the grid to the mass of the active material, and the MS value represents the amount of active material carried on the unit grid area.

Embodiment 2

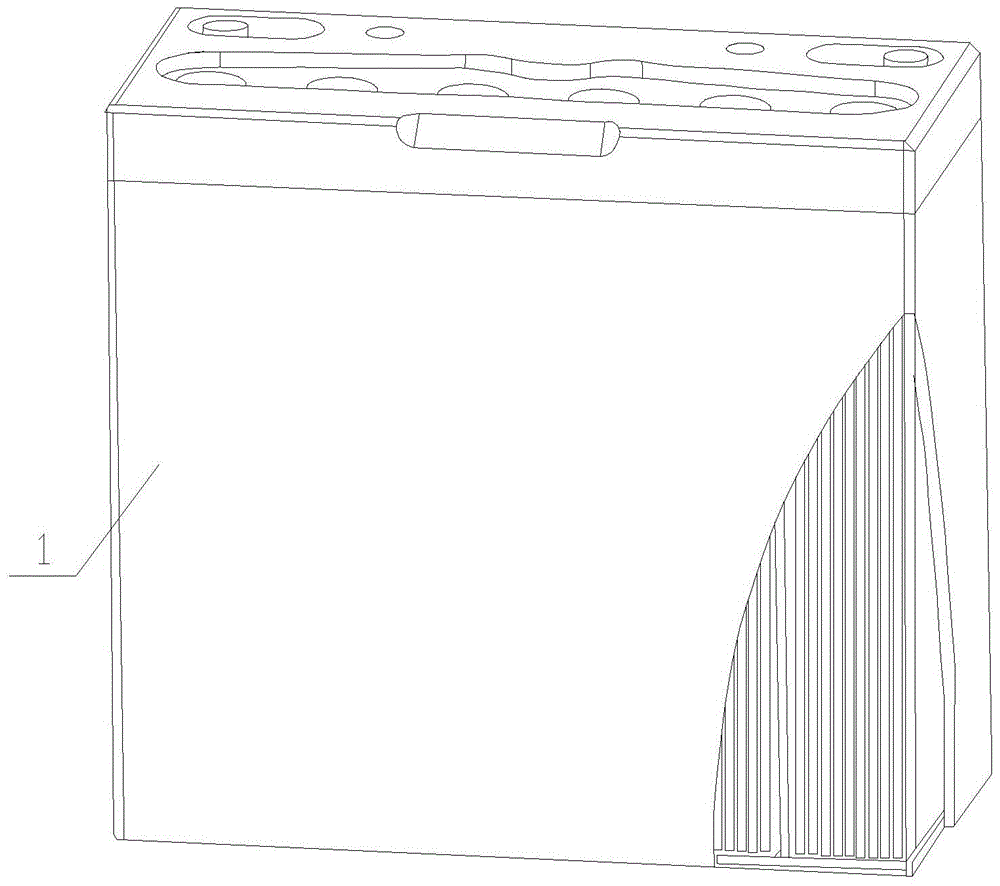

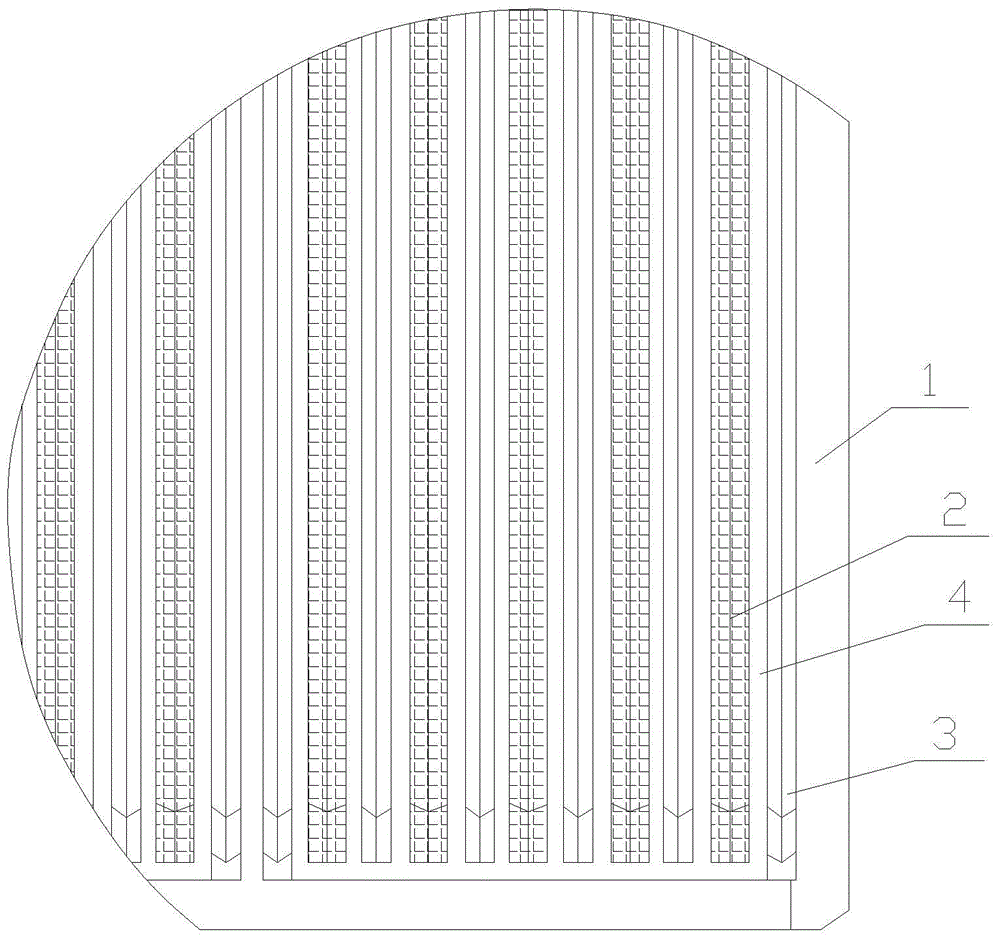

[0023] Such as figure 1 , figure 2 As shown, a storage battery prepared by using the plates of Example 1 includes a battery case 1, a positive plate 2, a negative plate 3, and a separator 4, and the positive plate 2, the negative plate 3, and the separator 4 are arranged inside the battery case 1, The inside of the battery case 1 is divided into 6 cells, each cell is equipped with five positive plates 2 and six negative plates 3, the positive plates 2 and the negative plates 3 are stacked alternately, and the gap between the positive plates 2 and the negative plates 3 The isolation is done by the separator 4. Positive plate 2 and negative plate 3 are key components. The thickness of positive plate 2 and negative plate 3 plays a decisive factor in the assembly of the battery, so as to increase the effective reaction area of the active material on the plate and improve the utilization rate of the active material. The external dimensions of the positive plate 2 It is: width ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com