Low voltage intelligent synchronous switch

A synchronous switch and low-voltage technology, which is applied in the direction of reactive power compensation, reactive power adjustment/elimination/compensation, etc., can solve the problems of poor overcurrent tolerance, sensitivity to heat and current impact, and short service life of composite switches. Achieve the effect of reducing the volume of the designed product, reducing the weight and saving the transformer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

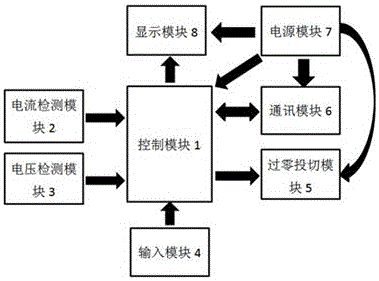

[0033] A low-voltage intelligent synchronous switch of the present invention such as figure 1 As shown, it mainly includes: control module 1, current detection module 2, voltage detection module 3, input module 4, zero-crossing switching module 5, communication module 6, power module 7 and display module 8; where control module 1 is connected with other The seven modules are connected, and the power module 7 is also connected to the zero-crossing switching module 5, the communication module 6 and the display module 8;

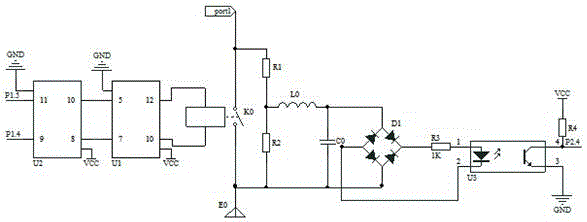

[0034] The control module 1 mainly includes a single-chip microcomputer and its peripheral circuits, and different pins of the single-chip microcomputer or pins of an expansion chip are connected with the remaining 7 modules. Described peripheral circuit is known technology, comprises the minimum system of single-chip microcomputer, JTAG program programming circuit and other external extension equipments. The single-chip microcomputer of this embodiment is a D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com