Method for producing grapefruit juice by employing ultra-high pressure technology

An ultra-high pressure technology, grapefruit juice technology, applied in ultra-high pressure food processing, food extraction, food science and other directions, can solve the problems of unequal output and deep processing utilization, limit and restrict the economic benefits of grapefruit, etc., to achieve strong antioxidant capacity, Not easy to brown and improve the effect of research progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1, utilize ultra-high pressure technology to produce pomelo juice and performance test thereof:

[0024] 1. Production of grapefruit juice using ultra-high pressure technology:

[0025] 1) Preparation of grapefruit juice: Pick grapefruits and weigh them, peel them, separate the inner and outer pericarps to obtain pulp, squeeze the juice with a screw juicer, and squeeze the pulp residue twice. Finally, filter through four layers of gauze, and continuously centrifuge at 2000r / min to obtain grapefruit juice. Mix the grapefruit juice evenly, put it into 60mL EVOH plastic bottles, tighten it by hand, and put it in a 4°C freezer for temporary storage for testing;

[0026] 2) HHP treatment: place the filled pomelo juice in the HHP sterilization equipment container, treat it at room temperature at 550MPa for 10min, and the average pressure increase rate and average pressure relief rate are 120MPa / min and 500MPa / min respectively;

[0027] 2. Performance test of grap...

Embodiment 2

[0057] Embodiment 2, utilize ultra-high pressure technology to produce pomelo juice and performance test in the process of its storage period:

[0058] Produce grapefruit juice with full reference to the preparation method in Example 1, and measure the main quality changes of grapefruit juice in the storage period process;

[0059] The performance test indicators during the storage period are as follows:

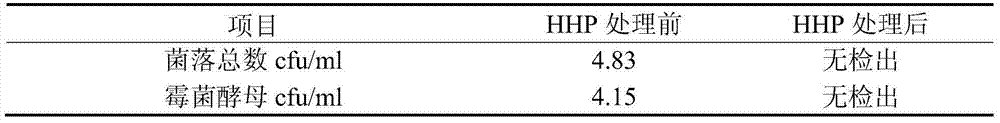

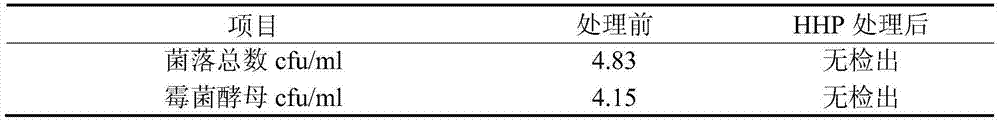

[0060] 1) Determination of the number of microorganisms: Stored at 4°C for 30 days, the samples obtained by HHP treatment did not detect the growth of mold and yeast, and the total number of colonies did not increase significantly, which met the national "Hygienic Standards for Fruit and Vegetable Juice Beverages" (GB19297-2003) Requirements for relevant microbial indicators (less than 2log10cfu / mL). It shows that the pomelo juice treated with HHP has good microbial stability during storage.

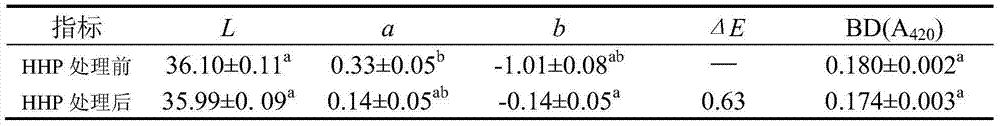

[0061] 2) Color measurement: Stored at 4°C for 30 days, with the prolongation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com