Reconstructed cut tobacco shredding and winnowing system

A technology of shredding and winnowing, which is applied in the fields of tobacco, tobacco preparation, and tobacco treatment. It can solve the problems of missed beating, short shredded tobacco that cannot meet the requirements of blending uniformity, and uneven length of shredded tobacco, so as to prevent dust, Optimize the effect of clean shreds and uniform distribution of shredded tobacco

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

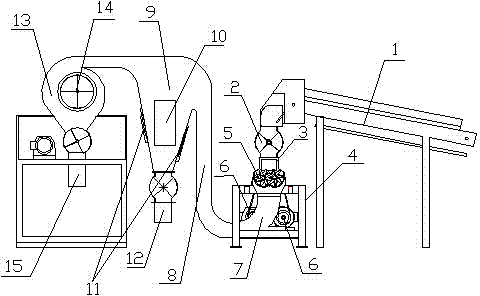

[0027] Such as figure 1 As shown, the reconstituted shredded tobacco shredded winnowing system of the present invention includes a high-frequency vibrating trough 1, a shredded device, a shredded device and a blanking device 13, and the shredded device includes a feeder 2, a shredded machine 5, a housing 3 and the frame 4, the silk cleaning device includes a conveying pipe 8 and a winnowing machine 9, the upper end of the feeder 2 is connected to the blanking box of the high-frequency vibrating tank 1, the housing 3 is fixed on the frame 4, and the upper part of the housing 3 is connected to the feeder 2. The lower end is connected. The lower part of the housing 3 is provided with a blanking port 7. The blanking port 7 is connected to the winnowing machine 9 through the conveying pipe 8. The outlet of the winnowing machine 9 is connected to the blanking device 13. The shredded machine 5 includes a shredded cutter And power unit, shred cutter is fixed in the housing 3.

[0028...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com