Detection method of laser processing groove

A technology of laser processing and detection method, which is applied in the direction of laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of inspection, device influence, inability to play rough groove incision, etc., and achieve the effect of reducing the time spent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

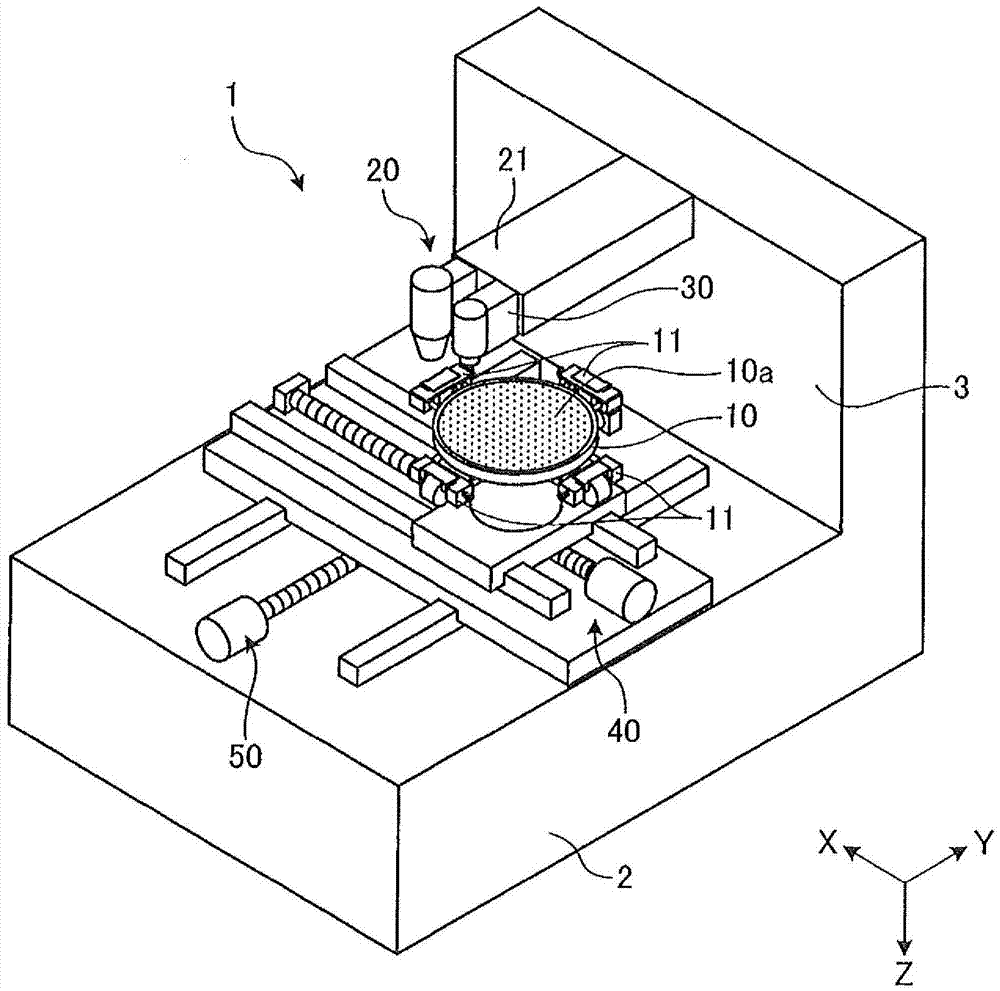

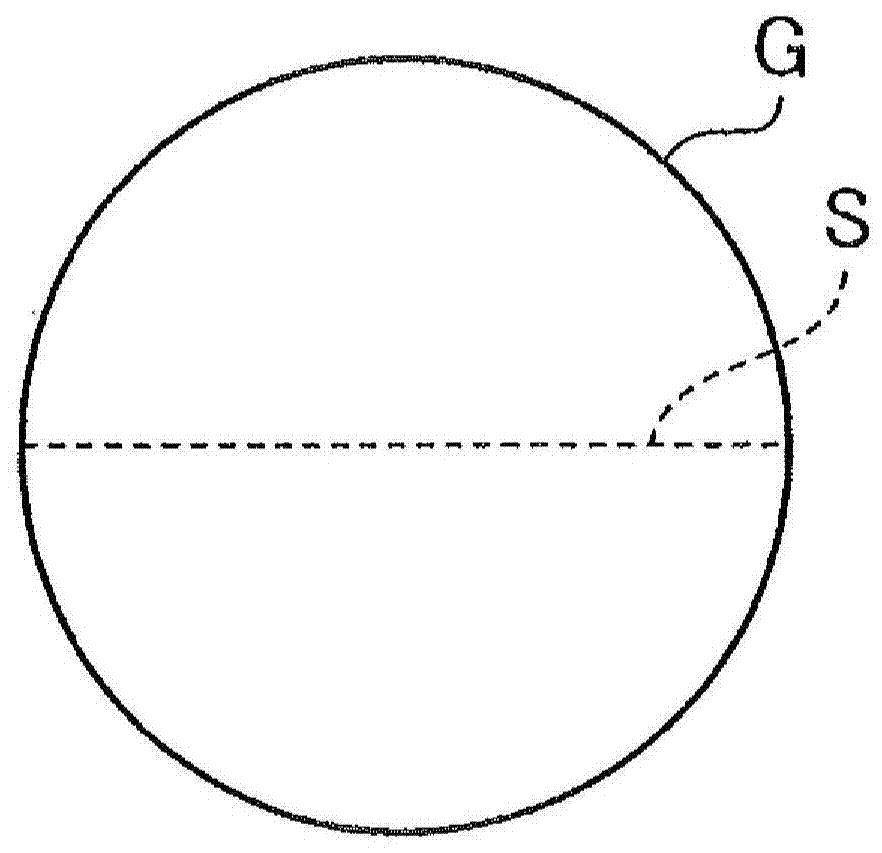

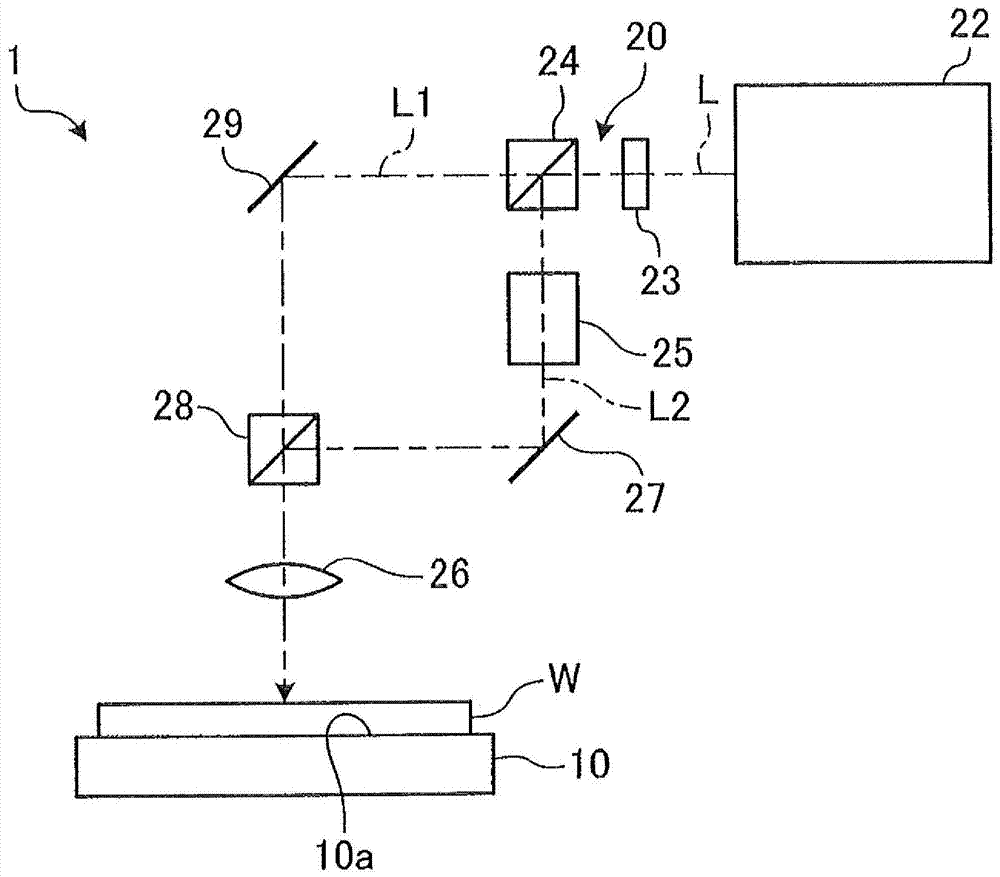

[0047] The detection method of the laser processing groove which concerns on embodiment of this invention is demonstrated based on drawing. figure 1 It is a perspective view which shows the structural example of the laser processing apparatus which concerns on the detection method of the laser processing groove which concerns on embodiment. figure 2 is showing figure 1 A diagram showing the image of the imaging member of the laser processing device. image 3 is showing figure 1 A diagram showing the structure of the laser beam irradiation member of the laser processing device shown. Figure 4is shown as figure 1 A perspective view of a wafer or the like to be processed by the laser processing apparatus shown.

[0048] The detection method (hereinafter, simply referred to as the detection method) of the laser processing groove of the embodiment is to use figure 1 The method performed by the laser processing apparatus 1 shown (that is, the method using the laser processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com