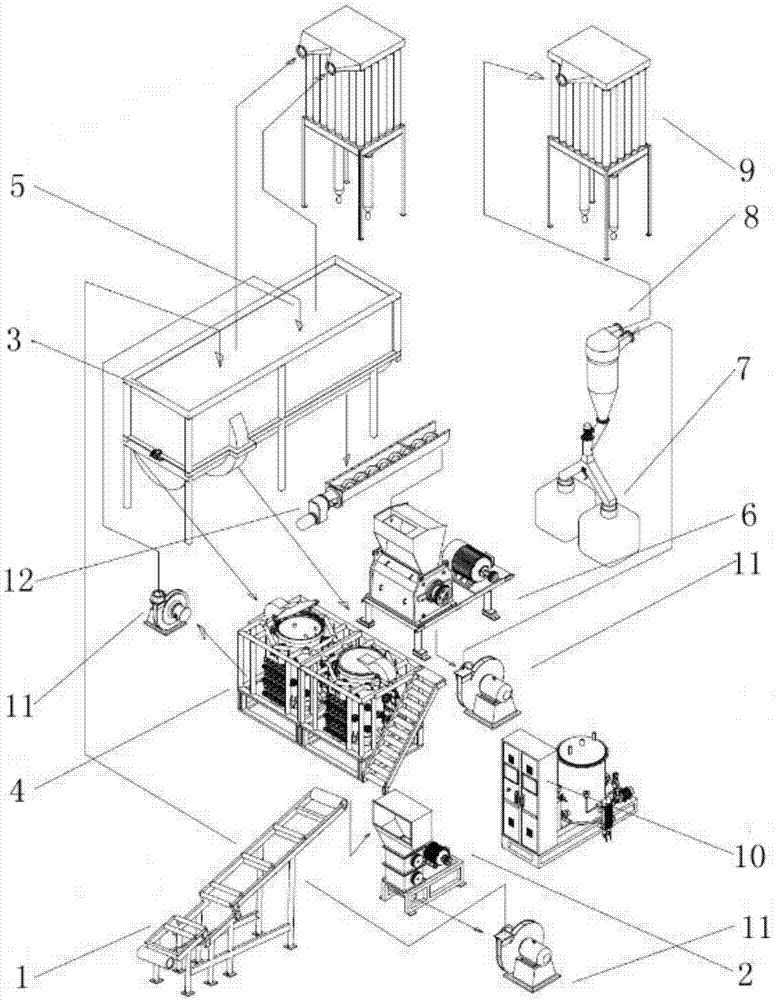

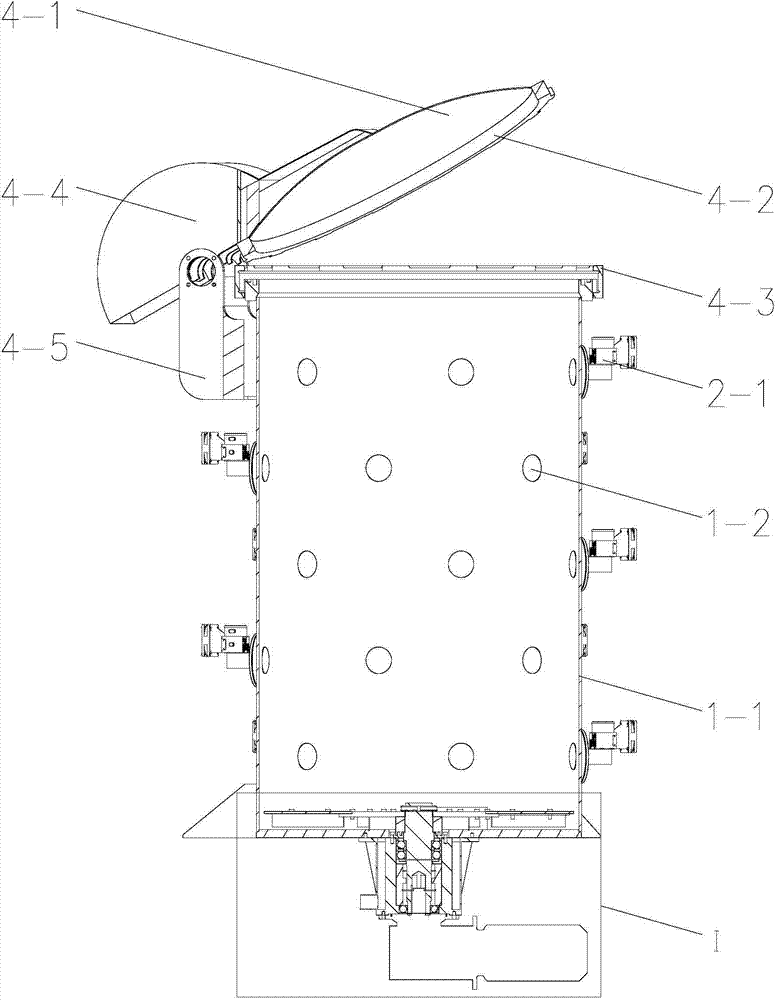

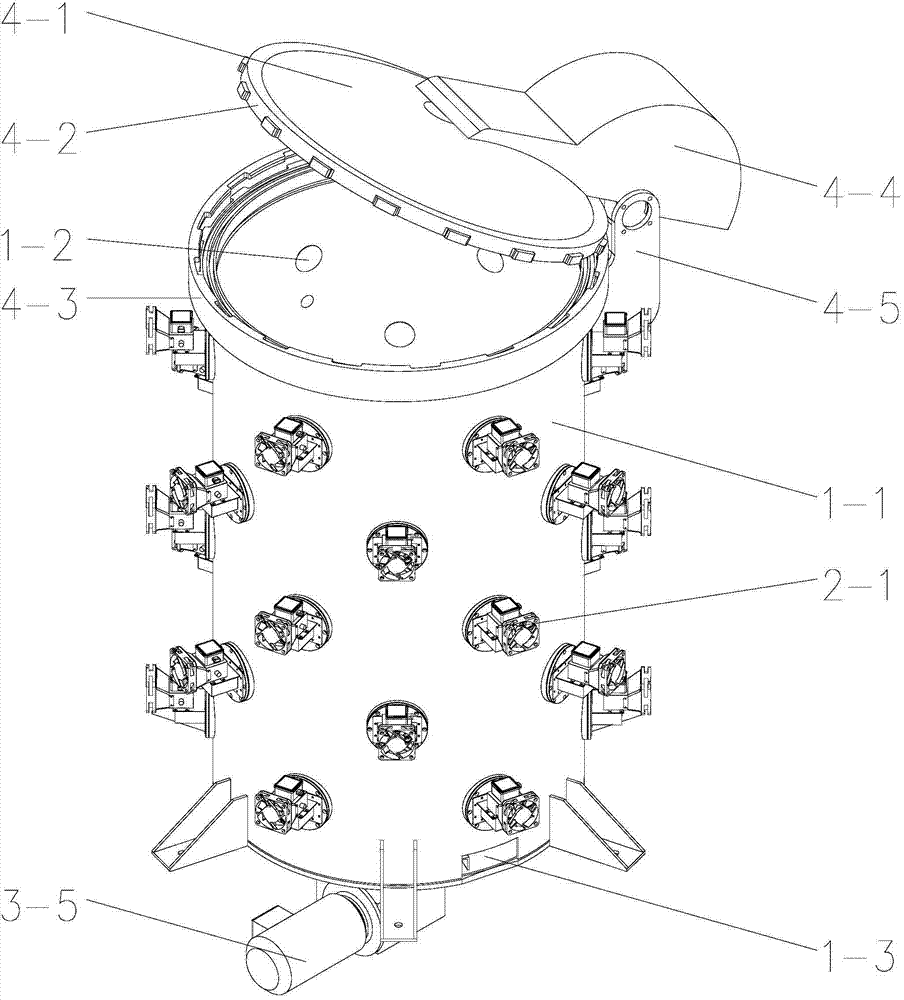

Method for recycling waste terylene fibers to obtain polyester raw materials as well as device system and microwave purifying equipment

A technology of polyester waste silk and purification equipment, which is applied in the field of recycling and reuse of polyester waste silk, can solve problems such as poor quality, decreased viscosity index of foam material, and low added value of foam material, so as to reduce the probability of oxidative degradation, Solve the polyester water degradation reaction and avoid the effect of overheating oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and specific embodiment, further illustrate the present invention, should be understood that these embodiments are only for illustrating the present invention and are not intended to limit the scope of the present invention, after having read the present invention, those skilled in the art will understand various aspects of the present invention Modifications in equivalent forms all fall within the scope defined by the appended claims of this application.

[0035] A method for recycling polyester waste silk to obtain raw polyester raw materials, specifically comprising the following steps:

[0036] Step 1: Cut and crush the messy polyester waste yarn, and make the balls into short fiber pompoms with a diameter of about 10mm, so that they have good fluidity and conveyability, and provide operating conditions for industrial production.

[0037] Step 2: Microwave heating is carried out on the short-fiber pompoms in a closed mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com