Manufacturing process of high toughness multilayer structure prepreg

A technology of multi-layer structure and manufacturing process, applied in the direction of lamination, layered products, lamination devices, etc., can solve the problem that the prepreg cannot be used normally, the degree of impregnation of the prepreg is low, and the viscosity of the high-toughness resin is high. problems, to achieve the effect of shortening the heating history, reducing the probability of voids, and reducing the production temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

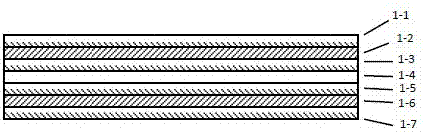

[0042] According to the schematic diagram of the prepreg structure, such as figure 1 , detail specific example 1.

[0043] According to the design, the resin content required for the prepreg is 40%, and the fiber surface density is 220g / m 2 , in order to guarantee the CAI value, it is necessary to produce such as figure 1 The epoxy resin prepreg with the seven-layer structure shown is resin layer 1-1, toughening layer 1-2, resin layer 1-3, fiber layer 1-4, resin layer 1-5, toughening layer 1-6. Resin layer 1-7.

[0044] Among them, fiber layers 1-4 are twill carbon fiber fabrics with a fiber surface density of 220 gsm.

[0045] Among them, the four resin layers 1-1, 1-3, 1-5, and 1-7 use the same tough epoxy resin. The resin component is bisphenol A resin system, the toughening agent is polyether ether ketone, and the curing agent is amine curing agent. Among them, the toughening agent part of the resin system accounts for 15%. The resin has a viscosity of 10000 cPs at 9...

Embodiment 2

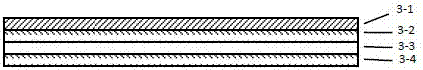

[0053] According to the schematic diagram of the prepreg structure, such as image 3 , detail the concrete example 2.

[0054] According to the design, the resin content required for the prepreg is 35%, and the fiber surface density is 145g / m 2 , in order to guarantee the CAI value, it is necessary to produce such as image 3 The shown four-layer structure of the cyanate resin prepreg includes a toughening layer 3-1, a resin layer 3-2, a fiber layer 3-3, and a resin layer 3-4.

[0055] Among them, the fiber layer 3-3 has a fiber surface density of 145g / m 2 12K carbon fiber.

[0056] Wherein, the two resin layers 3-2 and 3-4 use the same tough cyanate resin. The resin component is selected from cyanate resin system, the toughening agent is selected from polyether sulfone, and the curing agent is selected from acetylacetonate metal salt. Among them, the toughening agent part of the resin system accounts for 12%. The resin has a viscosity of 5000 cPs at 90°C.

[0057] Wher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com