Device and method for preparing composite material rib by using thermoplastic fiber reinforced resin-based prepreg tape

A resin-based and thermoplastic fiber-reinforced technology is applied in the field of devices for preparing composite material bars using thermoplastic fiber-reinforced resin-based prepreg tapes, which can solve the problems of low impregnation degree and high porosity, and achieve high impregnation degree, low porosity, and The effect of convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0061] Embodiment 1: Preparation of continuous carbon fiber reinforced PA6 bars with a diameter of 20mm

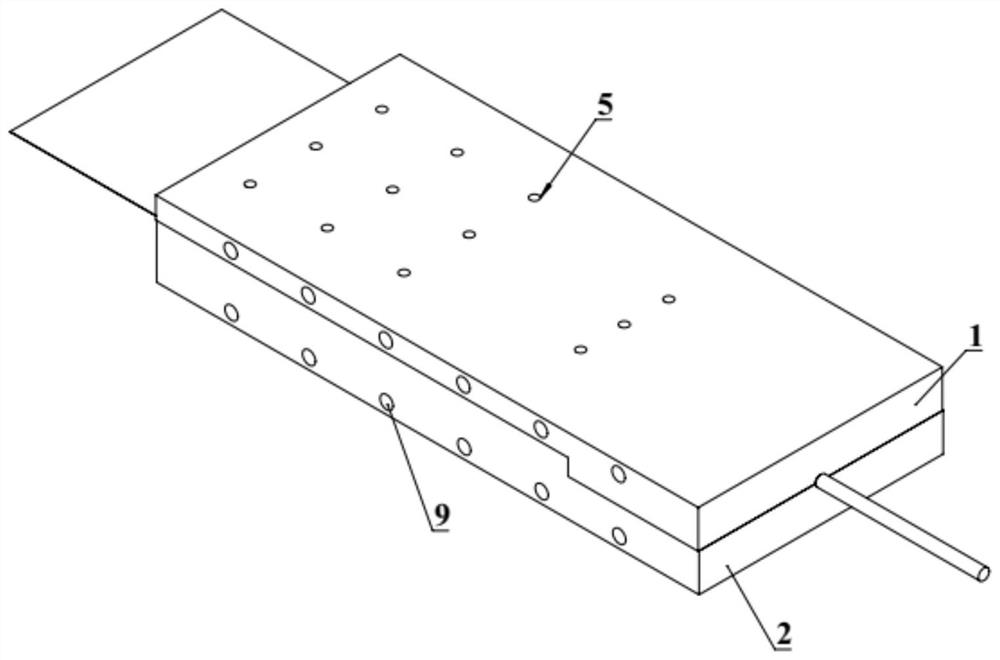

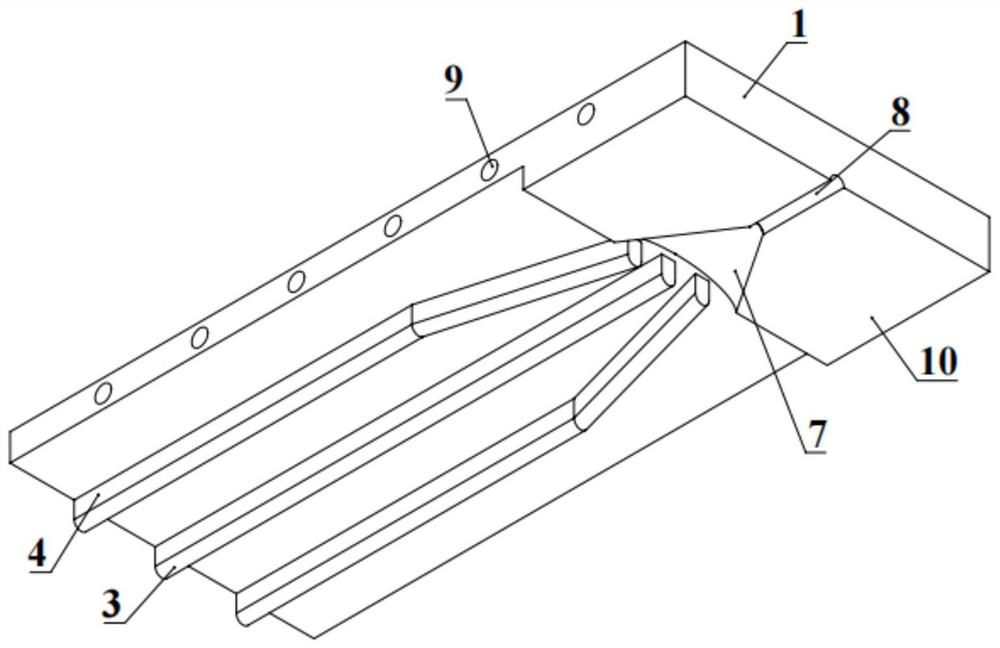

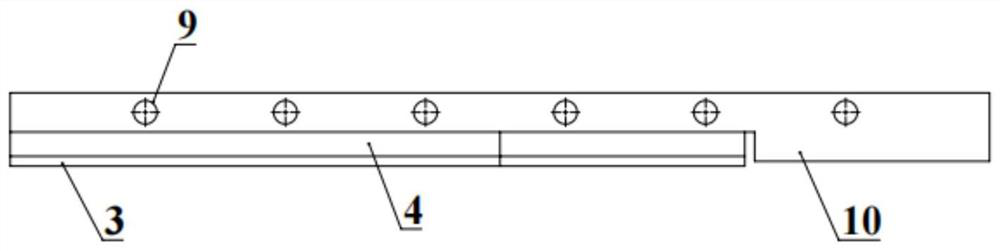

[0062] A used preparation device for continuously preparing composite material rods by using thermoplastic prepreg tapes includes a top cover 1 and a bottom groove 2, the top cover 1 is divided into a top cover guide area and a top cover shaping area, and the top cover The shaping area is a raised platform 10 set at the right end of the lower surface of the top cover 1 , the bottom groove 2 is divided into a bottom groove guide area and a bottom groove shaping area, and the bottom groove shaping area is on the bottom groove 2 . The concave platform 11 provided at the right end of the surface is provided with a plurality of elongated groove bases 4 in the guide area of the top cover and the guide area of the bottom groove, and a guide roller 3 is arranged in each elongated groove base 4 to guide the groove base 4. The roller 3 and the long groove base 4 are fixedly conn...

specific Embodiment approach 2

[0071] Embodiment 2: Preparation of continuous glass fiber reinforced PP rods with a diameter of 22 mm

[0072] A used preparation device for continuously preparing composite material rods by using thermoplastic prepreg tapes includes a top cover 1 and a bottom groove 2, the top cover 1 is divided into a top cover guide area and a top cover shaping area, and the top cover The shaping area is a raised platform 10 set at the right end of the lower surface of the top cover 1 , the bottom groove 2 is divided into a bottom groove guide area and a bottom groove shaping area, and the bottom groove shaping area is on the bottom groove 2 . The concave platform 11 provided at the right end of the surface is provided with a plurality of elongated groove bases 4 in the guide area of the top cover and the guide area of the bottom groove, and a guide roller 3 is arranged in each elongated groove base 4 to guide the groove base 4. The roller 3 and the long groove base 4 are fixedly conne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com