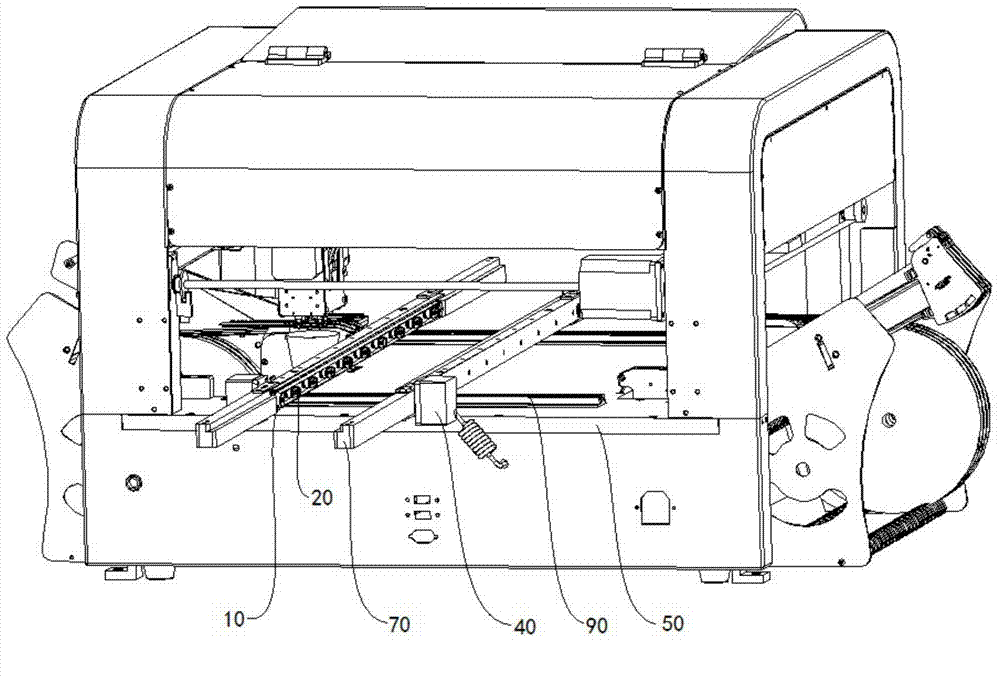

PCB transmission device

A conveying device and PCB board technology, applied in the directions of transportation and packaging, object supply, positioning objects, etc., can solve the problems of errors, difficulty in reducing the longitudinal height of the PCB board transmission and positioning structure, elastic deformation of the conveyor belt, etc., so as to prolong the service life. , not easy to deform, enhance the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

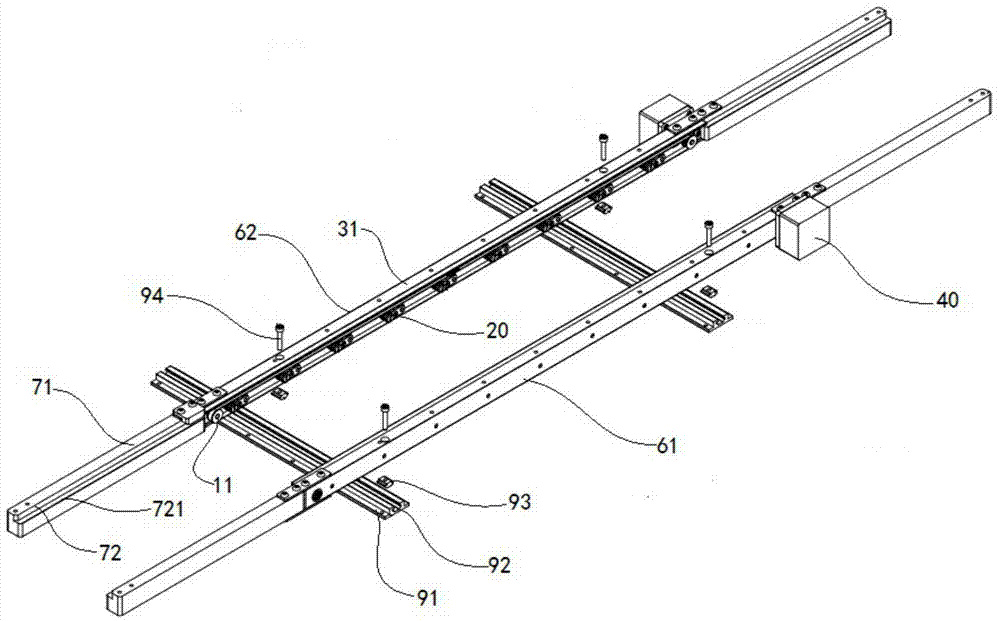

[0044] Embodiment 1: as Figures 1 to 5 As shown, the transmission mechanism 10 is composed of a transmission wheel 11 and a transmission belt 12, and the driving mechanism 40 is a motor, which drives the transmission wheel 11 to rotate.

[0045] Elastic supporting mechanism 20 comprises elastic part 21 and supporting head 22, and elastic part 21 is made up of rotating shaft 211, torsion spring 212, first side plate 213A, second side plate 213B, stress axis 214, torsion spring 212, first side plate 213A and the second side plate 213B are sleeved on the rotating shaft 211, the torsion spring 212 is sandwiched between the first side plate 213A and the second side plate 213B, and installed between the first side plate 213A and the second side plate 213B There is a stress shaft 214, and one end of the torsion spring 212 is fixed on the rotating shaft 211, and the other end is fixed on the stress shaft 214; One end away from the rotating shaft 211 is fixed between the first side p...

Embodiment 2

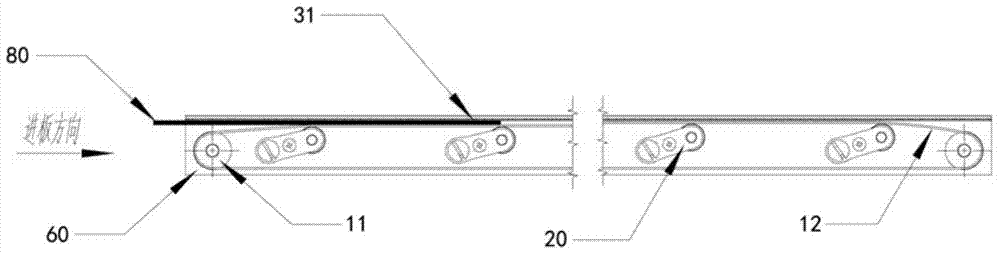

[0051] Embodiment 2: as Figure 6 As shown, the rest of the structure of this embodiment is the same as that of Embodiment 1, the main difference is that the guide mechanism 60 is omitted, and the suppression mechanism 30 includes a support side plate 32 and a pressing piece 31 arranged beside the transmission mechanism 10, and the support side plate 32 is not Attached to the conveyor belt 12, the supporting side plate 32 supports the pressing piece 31 so that it is located directly above the conveying mechanism 10. Since the PCB board 80 is always pressed under the pressing piece 31, the lateral offset of the PCB board 80 is not large. Existing placement machines are often equipped with a vision correction system, which can identify the offset error of the PCB board 80. As long as the conveyor belt 12 can withstand the impact of the placement operation without deformation, there will be no large deviation.

Embodiment 3

[0052] Embodiment 3: as Figure 7 As shown, the rest of the structure of this embodiment is the same as that of Embodiment 1, the main difference is that the elastic support mechanism 20 includes an elastic member 21 and a support head 22, and the elastic member 21 is composed of a rotating shaft 211, a torsion spring 212, a first The side plate 213A is composed of a torsion spring 212 and the first side plate 213A are sleeved on the rotating shaft 211, and a stress hole 215 is opened on the first side plate 213A close to the torsion spring 212, and one end of the torsion spring 212 is fixed on the rotating shaft 211, the other end is the stress end 216 fixed in the stress hole 215; the support head 22 is composed of a bearing 221 and an installation shaft 222, the bearing 221 is sleeved on the installation shaft 222, and the installation shaft 222 is fixed on the first side plate 213A away from the rotation One end of the shaft 211.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com