Y molecular sieve high in silica alumina ratio and abundant in secondary holes and preparation method therefor

A secondary pore, silicon-aluminum ratio technology, applied in the direction of crystalline aluminosilicate zeolite, octahedral crystalline aluminosilicate zeolite, etc., can solve the problems of limiting the range of molecular sieve raw materials, increasing hydrothermal dealumination to create mesopores, etc., to achieve The effect of widening the selection range of raw materials, low reagent cost, and enriching the secondary pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

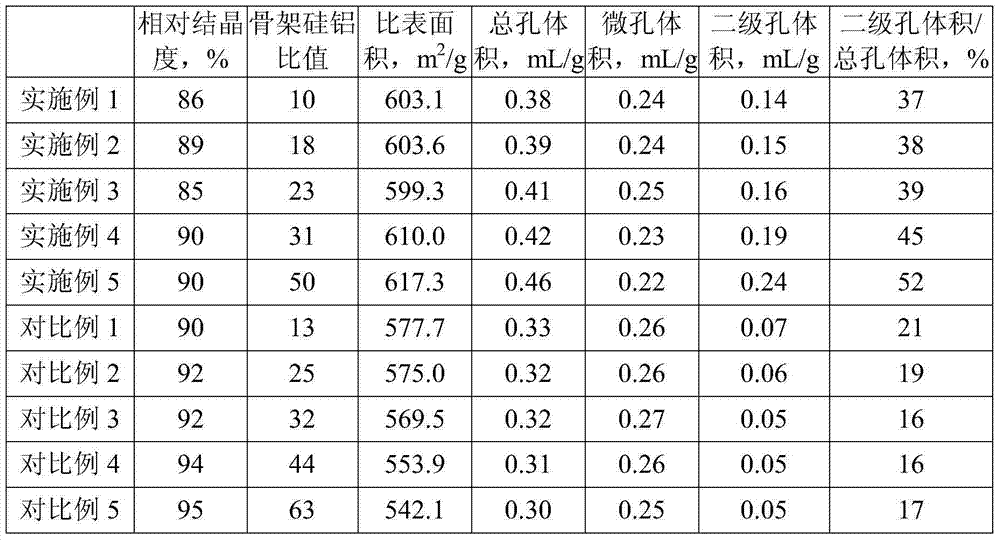

Embodiment 1

[0045] This example provides a Y molecular sieve with a high silicon-aluminum ratio and abundant secondary pores, which is prepared by the following steps:

[0046] Weigh 20.0g of the NaY zeolite sample that was dried overnight and place it in a quartz reaction tube, pass nitrogen gas into it, and do a good job of leak detection. Furnace heating program: From the initial temperature of 30°C to 500°C for 100 minutes, keep it for 120 minutes, then stop heating, when the temperature naturally drops to 270°C, pass through the 4 saturated N 2 At the same time, the temperature was raised to 430°C at a heating rate of 4°C / min for 40 minutes. After the reaction was completed, the SiCl 4 saturated N 2 , N 2 Continue purging for 120 minutes, then stop heating and cool down naturally, take out the sample and wash and dry to obtain the crude product;

[0047] Take 10 g of the crude product, add it to 200 mL of sodium hydroxide solution with a concentration of 0.1 mol / L, heat it in a w...

Embodiment 2

[0053] This example provides a Y molecular sieve with a high silicon-aluminum ratio and abundant secondary pores, which is prepared by the following steps:

[0054] Weigh 20.0g of the NaY zeolite sample that was dried overnight and place it in a quartz reaction tube, pass nitrogen gas into it, and do a good job of leak detection. Furnace heating program: From the initial temperature of 30°C to 500°C for 100 minutes, keep it for 120 minutes, then stop heating, when the temperature naturally drops to 270°C, pass through the 4 saturated N 2 At the same time, the temperature was raised to 510°C at a heating rate of 4°C / min for 1h. After the reaction was completed, the SiCl 4 saturated N 2 , alone N 2 Continue purging for 120 minutes, then stop heating and cool down naturally, take out the sample and wash and dry to obtain the crude product;

[0055] Take 10 g of the crude product, add it to 200 g of sodium hydroxide solution (concentration: 0.15 mol / L), heat in a water bath at...

Embodiment 3

[0061] This example provides a Y molecular sieve with a high silicon-aluminum ratio and abundant secondary pores, which is prepared by the following steps:

[0062] Weigh 20.0g of the NaY zeolite sample that was dried overnight and place it in a quartz reaction tube, pass nitrogen gas into it, and do a good job of leak detection. Furnace heating program: From the initial temperature of 30°C to 500°C for 100 minutes, keep it for 120 minutes, then stop heating, when the temperature naturally drops to 270°C, pass through the 4 saturated N 2 At the same time, the temperature was raised to 510°C at a heating rate of 3°C / min for 80 minutes. After the reaction was completed, the SiCl 4 saturated N 2 , N 2 Continue purging for 120 minutes, then stop heating and cool down naturally, take out the sample and wash and dry to obtain the crude product;

[0063] Take 10 g of the crude product, add it to 200 g of sodium hydroxide solution (concentration: 0.2 mol / L), heat it in a water bat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com