A kind of method of variable temperature dehydration and desorption of vinyl chloride

A technology of variable temperature dehydration, desorption, and vinyl chloride. It is used in the disproportionation separation/purification of halogenated hydrocarbons, organic chemistry, etc. It can solve problems such as equipment corrosion and affect product quality, and achieve the effect of preventing corrosion, simple structure and improving quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

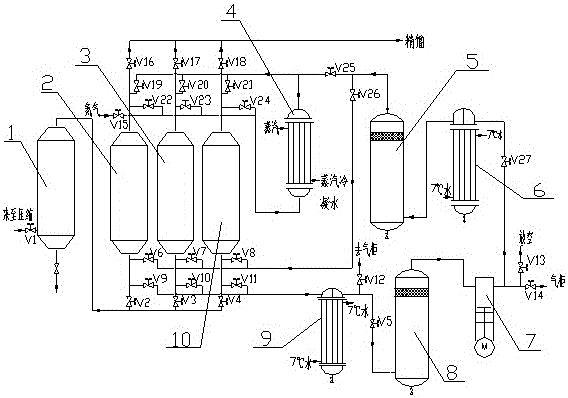

[0025] Refer to attached figure 1 , a method for variable temperature dehydration and desorption of vinyl chloride, comprising an adsorber connected in sequence, a cooler I, a steam-water separator I, a booster, a cooler II, a steam-water separator II, a heater, a dryer A, and a dryer B, dryer C; the steps are as follows:

[0026] Vinyl chloride gas with a temperature of 40-50°C and a pressure of 0.50-0.55MPa sent from the compression process enters the adsorber through the valve V1, and after the oil and heavy molecular gases are removed through the adsorber, the valves V2 and V16 are opened. The vinyl chloride gas enters the dryer A, where the moisture in the vinyl chloride gas is removed. The vinyl chloride gas comes out from the top of the dryer A and sent to the rectification process. When the moisture absorbed by the dryer A reaches a certain level, the valves V2 and V16 are closed. ;

[0027] Open the valves V9 and V12, and the gas in the adsorber A is depressuriz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com