Flame-retardant finishing method of reactive expansion flame retardants on cotton fabrics

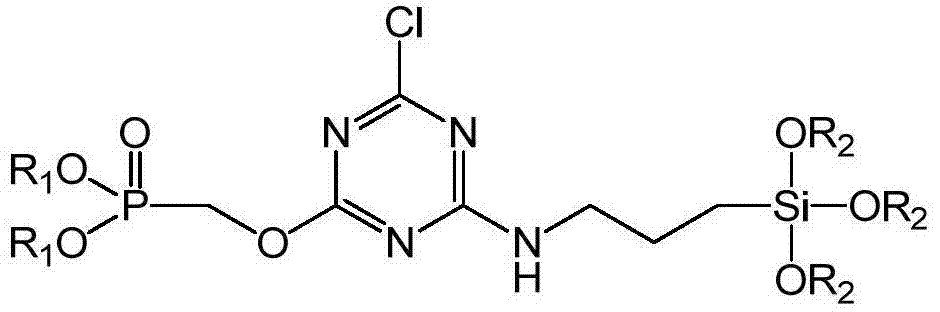

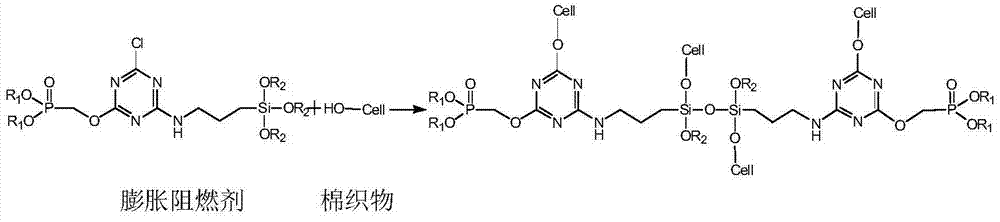

An intumescent flame retardant and flame retardant finishing technology, which is applied in fiber treatment, plant fiber, textiles and paper making, can solve the problems of large amount of flame retardant addition, secondary pollution, poor flame retardant durability, etc., and achieve improved flame retardant Flame durability, improved reactivity, and good flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

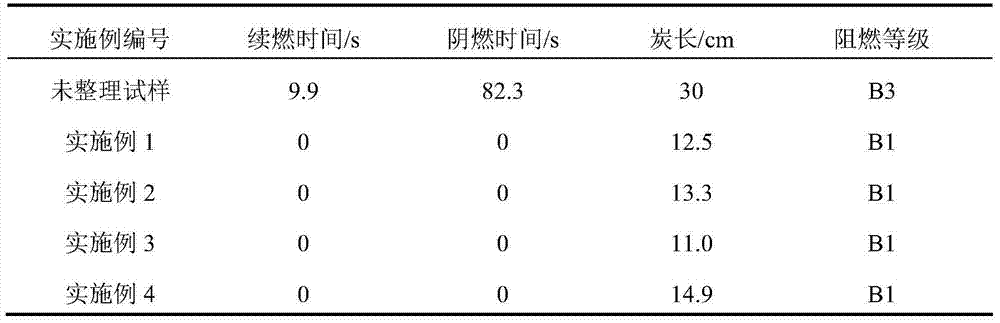

Embodiment 1

[0025] A method for flame-retardant finishing of cotton fabrics with a reactive intumescent flame retardant, the steps of which are as follows:

[0026] (1) Preparation of flame retardant finishing liquid: wherein the volume ratio of flame retardant 150g / L, catalyst sodium hypophosphite 30g / L, solvent ethanol and water is 7:3; R in the flame retardant molecule 1 for -CH 3 , R 2 for -CH 2 CH 3 ;

[0027] (2) Soak the commercially available plain weave cloth in the flame-retardant finishing solution at 40°C after alkali washing, desizing and drying, soak for 60 minutes for the first time, and 5 minutes for the second time, and perform two dipping and two rolling processes on the cotton fabric at 0.7 MPa deal with;

[0028] (3) Dry the padded cotton fabric at 80°C for 5 minutes, and finally cure it at 160°C for 3 minutes to obtain a flame-retardant cotton fabric. The oxygen index is 30.8%, and the flame retardant grade reaches B1 grade.

Embodiment 2

[0030] A method for flame-retardant finishing of cotton fabrics with a reactive intumescent flame retardant, the steps of which are as follows:

[0031] (1) Preparation of flame retardant finishing liquid: wherein the flame retardant content is 250g / L, the catalyst boric acid is 50g / L, and the volume ratio of solvent ethanol to water is 7:3; R in the flame retardant molecule 1 for -CH 2 CH 3 , R 2 for -CH 2 CH 3 ;

[0032] (2) Soak the commercially available plain weave cloth in the flame-retardant finishing solution at 35°C after alkaline washing, desizing and drying, soak for 50 minutes for the first time, and 4 minutes for the second time, and perform two-dipping and two-rolling process on the cotton fabric at 0.7MPa deal with;

[0033] (3) Dry the padded cotton fabric at 90°C for 7 minutes, and finally cure it at 170°C for 4 minutes to obtain a flame-retardant cotton fabric. The oxygen index is 29.5%, and the flame retardant grade reaches B1 grade.

Embodiment 3

[0035] A method for flame-retardant finishing of cotton fabrics with a reactive intumescent flame retardant, the steps of which are as follows:

[0036] (1) Preparation of flame retardant finishing liquid: wherein the content of flame retardant is 300g / L, the content of catalyst disodium hydrogen phosphate is 40g / L, and the volume ratio of solvent ethanol to water is 7:3; R in the flame retardant molecule 1 for -CH 3 , R 2 for -CH 3 ;

[0037] (2) Soak the commercially available plain weave cloth in the flame-retardant finishing solution at 35°C after alkali washing, desizing and drying, soak for 40 minutes for the first time, and 3 minutes for the second time, and perform two dipping and two rolling processes on the cotton fabric at 0.7 MPa deal with;

[0038] (3) Dry the padded cotton fabric at 100°C for 6 minutes, and finally cure it at 160°C for 5 minutes to obtain a flame-retardant cotton fabric. The oxygen index is 31.2%, and the flame retardant grade reaches B1 gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com