Environment-friendly plastics-absorption double-surface coated white board paper and preparation technology thereof

A double-sided coating and preparation technology, which is applied in the field of papermaking, can solve the problems of poor printing ink absorption, immature process technology, and low bonding strength, and achieve good printing ink absorption, moderate coating strength, and improved air permeability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

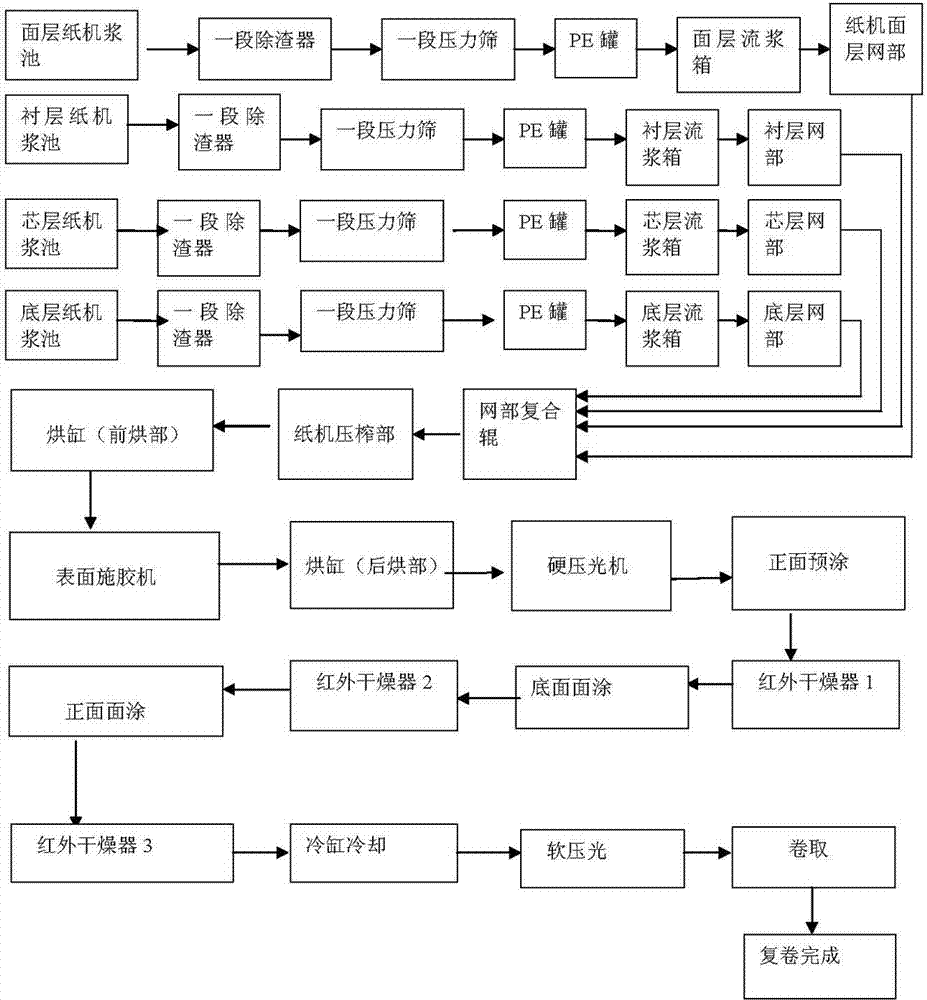

Method used

Image

Examples

Embodiment 1

[0040] A preparation process of environment-friendly plastic-absorbing double-sided coated white board paper, comprising the following process steps:

[0041] Step A, the preparation of each layer of pulp raw material: including the preparation of surface layer bleached chemical pulp layer, liner waste paper pulp layer, core layer waste paper pulp layer and bottom bleached chemical pulp layer slurry, wherein the mass ratio of each layer of slurry raw material is :

[0042] The pulp of the surface bleached chemical pulp layer is composed of 50% LBKP pulp and 50% DMOW pulp;

[0043] The slurry of the liner waste paper pulp layer is DIP pulp;

[0044] The pulp of the core waste paper pulp layer is composed of 70% MW pulp, 20% BCTMP pulp and 10% broke pulp; the pulp of the bottom bleached chemical pulp layer is composed of 30% LBKP pulp and 70% DMOW pulp.

[0045] The sum of the mass ratios of the above layers of slurry raw materials is 100%.

[0046]Among them, the LBKP used i...

Embodiment 2

[0057] A preparation process of environment-friendly plastic-absorbing double-sided coated white board paper, comprising the following process steps:

[0058] Step A, the preparation of each layer of pulp raw material: including the preparation of surface layer bleached chemical pulp layer, liner waste paper pulp layer, core layer waste paper pulp layer and bottom bleached chemical pulp layer slurry, wherein the mass ratio of each layer of slurry raw material is :

[0059] The pulp of the surface bleached chemical pulp layer is composed of 45% LBKP pulp and 55% DMOW pulp;

[0060] The slurry of the liner waste paper pulp layer is DIP pulp;

[0061] The pulp of the core waste paper pulp layer is composed of 65% MW pulp, 25% BCTMP pulp and 10% broke pulp; the pulp of the bottom bleached chemical pulp layer is composed of 25% LBKP pulp and 75% DMOW pulp.

[0062] The sum of the mass ratios of the above layers of slurry raw materials is 100%.

[0063] Among them, the LBKP used ...

Embodiment 3

[0074] A preparation process of environment-friendly plastic-absorbing double-sided coated white board paper, comprising the following process steps:

[0075] Step A, the preparation of each layer of pulp raw material: including the preparation of surface layer bleached chemical pulp layer, liner waste paper pulp layer, core layer waste paper pulp layer and bottom bleached chemical pulp layer slurry, wherein the mass ratio of each layer of slurry raw material is :

[0076] The pulp of the surface bleached chemical pulp layer is composed of 55% LBKP pulp and 45% DMOW pulp;

[0077] The slurry of the liner waste paper pulp layer is DIP pulp;

[0078] The pulp of the core waste paper pulp layer is composed of 75% MW pulp, 20% BCTMP pulp and 5% broke pulp; the pulp of the bottom bleached chemical pulp layer is composed of 35% LBKP pulp and 65% DMOW pulp.

[0079] The sum of the mass ratios of the above layers of slurry raw materials is 100%.

[0080] Among them, the LBKP used i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com