Steel sheet pile protection system for tidal range area and water level fluctuation area and construction method thereof

A water level change area and protection system technology, applied in the direction of sheet pile walls, protection devices, infrastructure engineering, etc., can solve the problems of ineffective corrosion protection of steel sheet piles, achieve the effects of reducing labor intensity, eliminating mechanical coordination, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific drawings and embodiments.

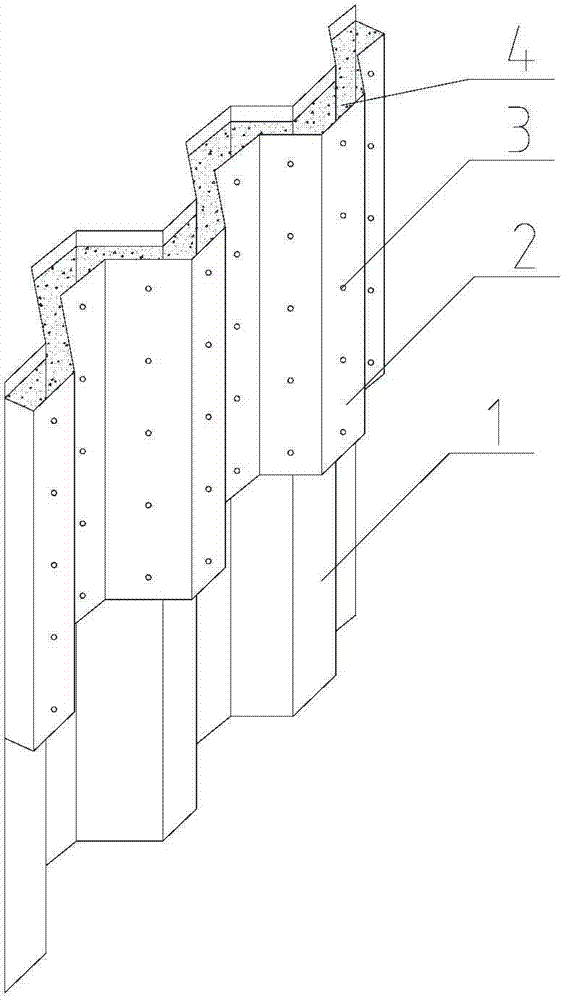

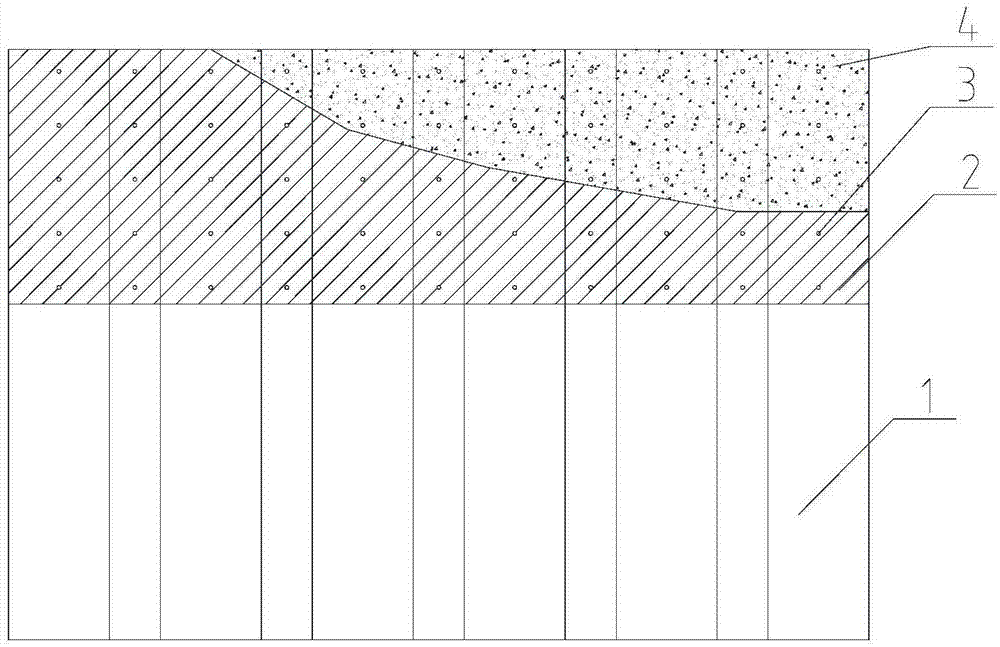

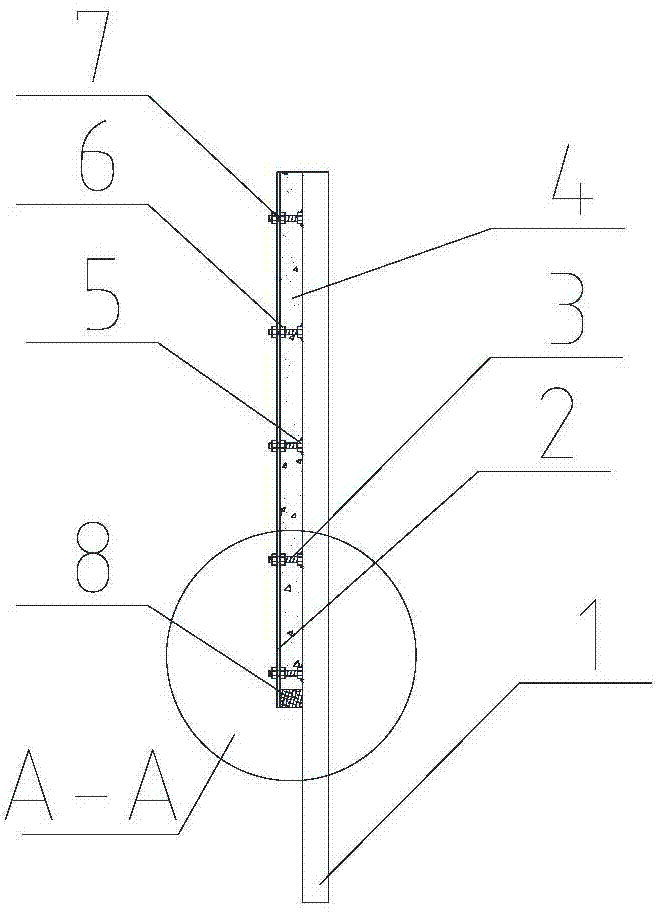

[0026] Such as Figure 1~5 Shown is the steel sheet pile protection system of the present invention, which has a fiberglass armor plate 2 that matches the outer surface profile of the steel sheet pile 1 and is pre-drilled with installation holes 9 at equal intervals. Bolts 3 penetrate through the installation holes 9, and the bolts 3 An inner positioning nut 6 and an outer positioning nut 7 are threadedly connected to the inner and outer sides of the mounting hole 9 respectively. The inner side mentioned here refers to the side of the glass fiber armor plate facing the steel sheet pile 1, and the outer side is the side facing away from the steel sheet pile. The outer surface of the steel sheet pile 1 is welded with fixing nuts 5 corresponding to the positions of each installation hole, and the bolts 3 are threadedly connected to the fixing nuts 5 to keep a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com