Automatic calibration system and method for electronic-controlled engine fuel oil parameters

An electronically controlled engine and calibration system technology, applied in engine components, engine control, engine testing, etc., can solve problems such as error-prone and large workload, and achieve the effect of reducing work intensity and test error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

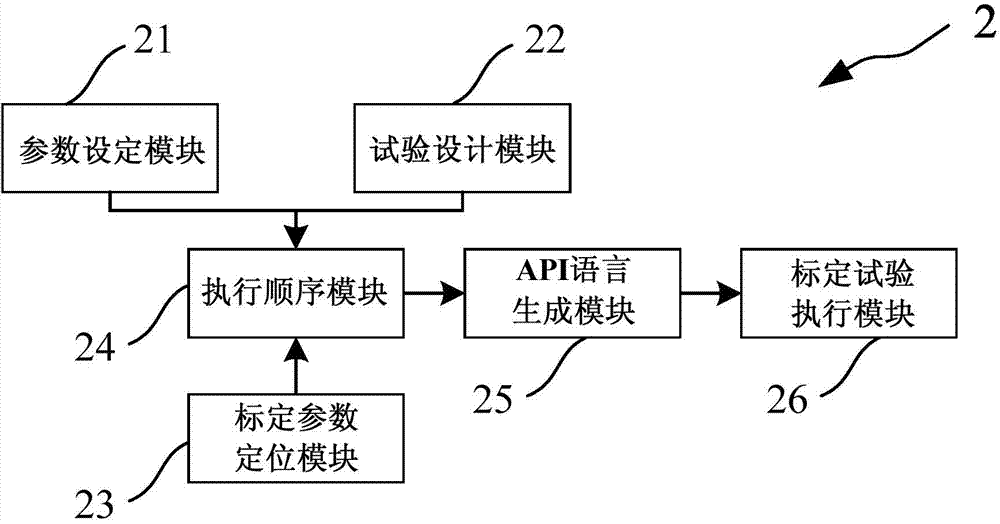

[0060] Such as figure 2 As shown, the present invention provides an electronically controlled engine fuel parameter automatic calibration system 2, comprising:

[0061] A parameter setting module 21 , an experiment design module 22 , a calibration parameter positioning module 23 , an execution sequence module 24 , an API language generation module 25 and a calibration test execution module 26 .

[0062] The parameter setting module 21 is used for selecting fuel injection parameters and setting the range of the fuel injection parameters. In this embodiment, the fuel injection parameters include main fuel injection quantity, number of injector holes, injector hole diameter, rail pressure or fuel injection timing. In this embodiment, the parameter setting module 21 is an application program module, which needs to call the API interface to control the operating system to realize the selection of the fuel injection parameters and the setting of the range of the fuel injection par...

Embodiment 2

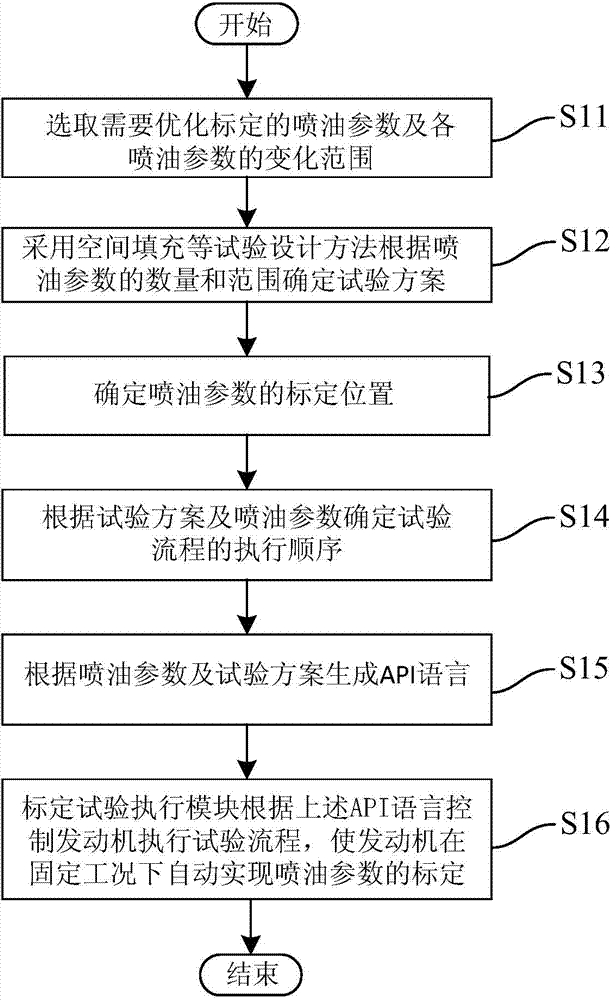

[0069] Such as image 3 As shown, the present invention provides an automatic calibration method for an electronically controlled engine fuel parameter automatic calibration system based on a point calibration mode. The point calibration mode is suitable for optimal calibration of fuel injection parameter combinations at a certain operating point, including the following steps:

[0070] Step S11: the parameter setting module 21 calls the API interface to select the fuel injection parameters to be optimized and calibrated and the variation range of the fuel injection parameters.

[0071] Specifically, in this embodiment, the fuel injection parameters are selected as rail pressure and fuel injection timing, the variation range of the rail pressure is set to 90-130 MPa, and the variation range of the fuel injection timing is set to 0~20 crank angle.

[0072] Step S12: The test design module 22 invokes the API interface, and uses space filling and other test design methods to det...

Embodiment 3

[0079] Such as Figure 6 As shown, the present invention provides an automatic calibration method for an electronically controlled engine fuel parameter automatic calibration system based on the line calibration mode. The surface line calibration mode is suitable for optimal calibration of a certain fuel injection parameter in transient or excessive conditions. Include the following steps:

[0080] Step S21: The parameter setting module 21 calls the API interface to select the fuel injection parameters that need to be optimized and calibrated and the variation range of the fuel injection parameters. In this embodiment, the main fuel injection quantity and fuel injection timing are selected as the fuel injection parameters.

[0081] Step S22: The experimental design module 22 calls the API interface to determine the initial working point and the ending working point of the calibration path, formulate the calibration path according to spline curves with different characteristic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com