Tray piston type swing driving machine capable of mechanically driving a piston to act on fluid load

A mechanically driven, fluid-loaded technology, applied in the direction of oscillating piston machinery, oscillating piston pumps, components of pumping devices for elastic fluids, etc., can solve problems such as low corrosion resistance, complex structure, and low mechanical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

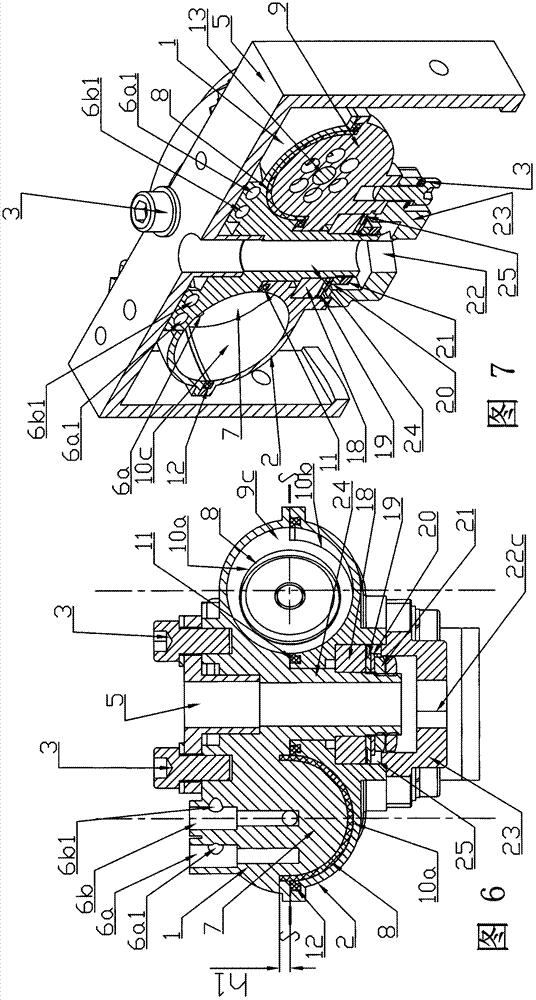

[0073] refer to Figure 29 and 30 , as a partial embodiment 2 of the detachable piston sheet combined with the tray groove;

[0074] Shown in the figure is the detachable piston plate of oblong outline 29a, which is provided with a protruding ring 44 larger than the cross-sectional profile of the tray groove at the joint with the keyway, the static seal of the detachable piston plate The part is a static seal half ring 44b, and a static seal half ring groove 44a with a depression along the tangential direction of the rotation center circle is also provided on the detachable piston plate. The static seal half ring 44b is arranged on the static seal half ring In the groove 44a, a convex groove 8b is provided on the sliding engagement surface of the piston plate and the groove of the tray, and the semi-ring sealing ring 8 is fixed in the convex groove on the piston plate matching the section of the static sealing half ring.

Embodiment 3

[0075] refer to Figure 31 and 32 , as yet another partial embodiment 3 of the detachable piston sheet combined with the tray groove;

[0076] In the figure, a part of the detachable piston plate with circular contour line 36b is inserted into the tray groove and fixed into a detachable combined structure, insert the joint part of the detachable piston plate on the tray groove and utilize the hole to tighten The firmware 3 is fixed; a static seal is provided between the joint surface of the detachable piston plate and the groove of the tray. The static seals of the detachable piston plate are two static seal half-rings 44b, and two static seal half-ring grooves 44a are provided with depressions along the tangent direction of the center circle of rotation on the detachable piston plate. The sealing half ring 44b is arranged in the static sealing half ring groove 44a; the fastener 3 for the hole is a screw, and the two screws are screwed on the threaded hole 36f of the detacha...

Embodiment 5

[0081] The difference between this embodiment and Embodiment 4 is that the mechanically driven piston acting on the fluid load system is a system in which the mechanically driven single-acting piston acts on the fluid load to deliver fluid in two directions. The groove of the fixed tray is provided with a combination of n pairs of double stationary piston pieces and double swinging piston pieces, each pair of combination has two stationary piston pieces and two swinging piston pieces; There is an independent working chamber 10c between the outer angle γ of the normal surface of the plumb bob of two stationary piston plates; an independent working chamber 10c is provided and communicated with n sets of inlet and exhaust pressure-feeding fluid passages, and the two stationary piston plates lead The wall of the fixed tray in the range where the inner included angle of the hammer surface is β is provided with an external drain fluid channel 6a, and a section of drain fluid channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com