Medium-wave infrared continuous zooming camera shot and control method thereof

A zoom lens and infrared technology, applied in the lens field, can solve problems such as loss and blurred targets, and achieve the effects of improved vibration resistance, short magnification compensation stroke, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

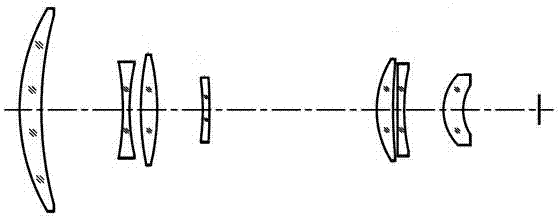

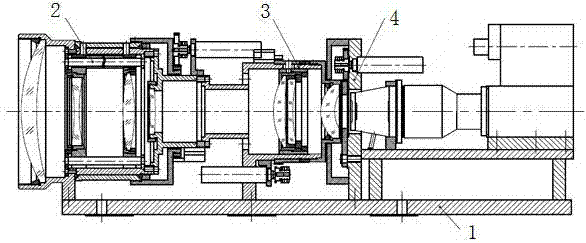

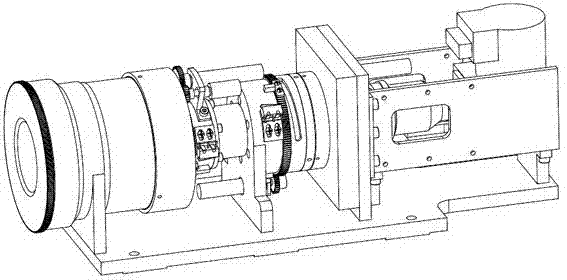

[0026] Such as Figure 1-8 As shown, a medium-wave infrared continuous zoom lens, the mechanical structure of the lens includes a zoom assembly, a focus assembly, and a detector assembly that are sequentially installed and connected to the connecting base plate from left to right, and the zoom assembly includes a front fixed lens A , variable power lens B, compensation lens C, rear fixed lens D and zoom mechanism, the focusing assembly includes secondary imaging lens group E and focusing mechanism, the detector assembly includes a baffle switching mechanism, a detector and a detector frame ; In the optical system of the lens, a front fixed lens A, a variable power lens B, a compensation lens C, a rear fixed lens D, and a secondary imaging lens group E are arranged successively along the incident direction of the light from left to right, and the secondary The imaging lens group E is sequentially provided with a positive lens E-1, a negative lens E-2 and a positive lens E-3, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com