Tea drier

A drying machine and tea technology, applied in the field of agricultural machinery, can solve the problems of poor fragrance, low production efficiency, high broken rate, and achieve the effects of reducing the broken rate, simple structure and stable movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

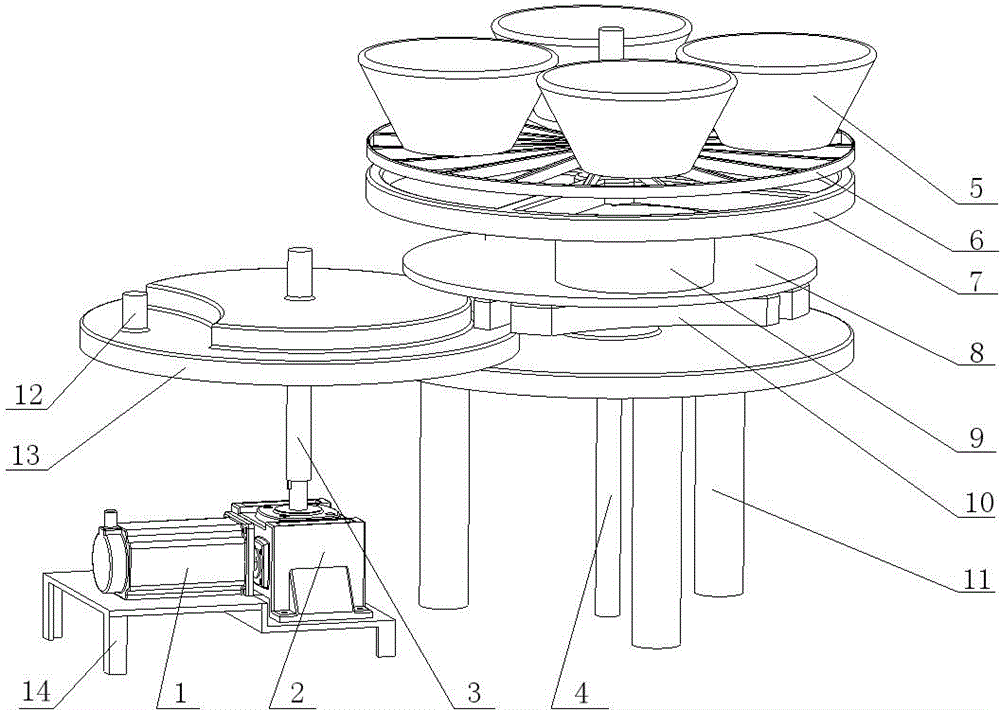

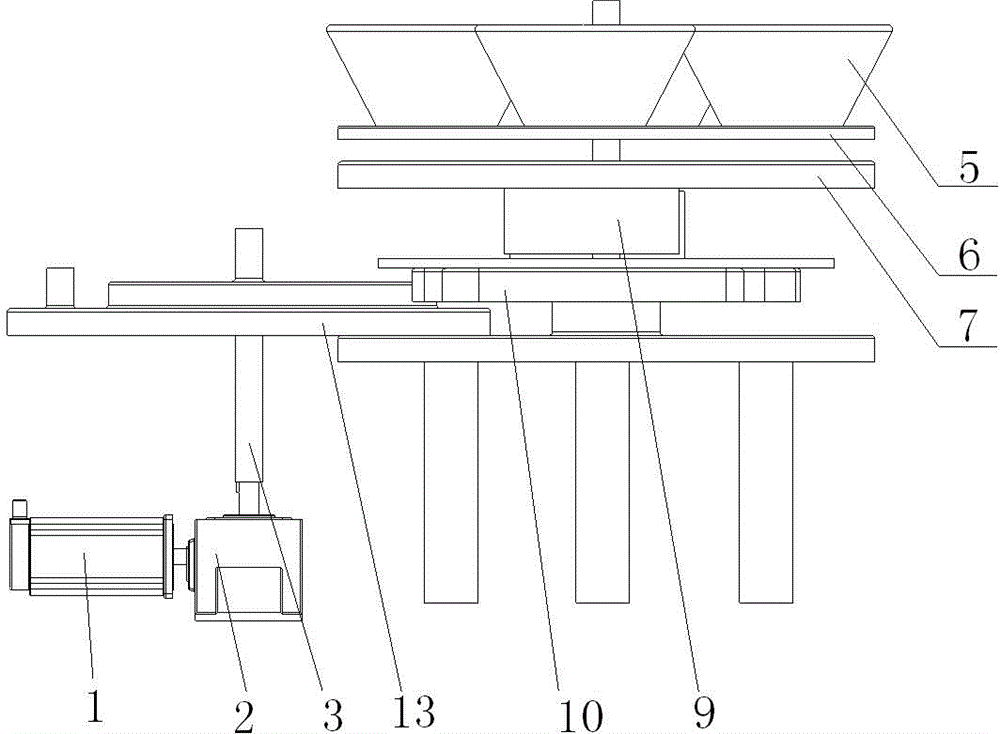

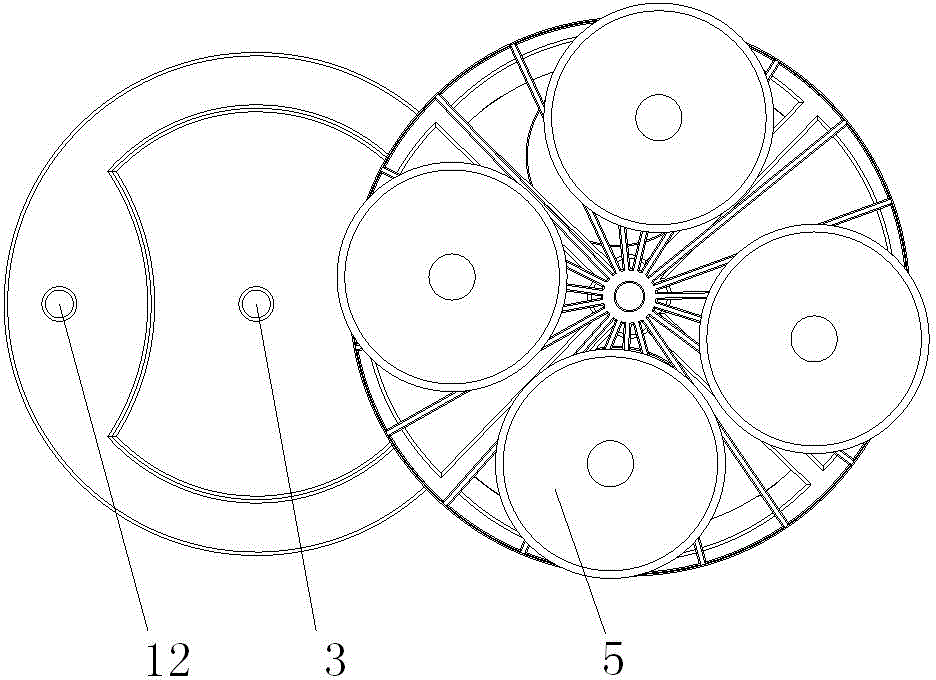

[0030] see figure 1 , figure 2 , image 3 , a tea drying machine, including a driving mechanism, a driven mechanism, a sheave mechanism, a drying assembly

[0031] The active mechanism includes a motor 1, a reducer 2 connected to the motor, a casing 3, and a puller 13; the motor 1 and the reducer 2 are installed on a mounting base 14;

[0032] The reducer 2 is a bevel gear reducer, the output shaft of the reducer 2 is arranged upright, and the sleeve 3 is fixedly sleeved on the output shaft of the reducer 2;

[0033] The upper end of the puller 13 is fixedly sleeved with the casing 3, and the middle part of the puller 13 is a round table with an arc-shaped gap, and a round pin 12 is arranged on the dial 13 corresponding to the arc-shaped gap of the round table;

[0034] The driven mechanism includes a frame 11, a rotating shaft 4, and a sheave 10;

[0035] Described frame 11 is the round table shape of three legs, and rotating shaft 4 is vertically arranged on the top pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com