Safe and reliable circulating water washing type waste gas treatment system

A technology for waste gas treatment and waste gas treatment device, which is applied in the separation of dispersed particles, chemical instruments and methods, combined devices, etc., can solve the problems of heavy maintenance work, large equipment area, poor treatment effect, etc., to ensure penetration efficiency and irradiation intensity, low operating cost, and the effect of avoiding damage to the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

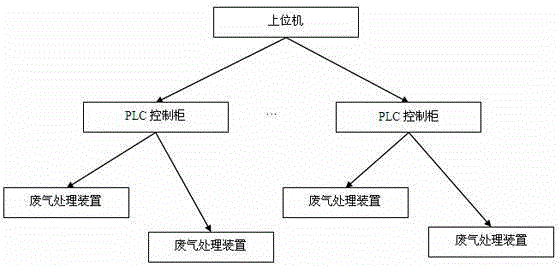

[0024] Describe technical scheme of the present invention in further detail below in conjunction with accompanying drawing: as figure 1 As shown, a safe and reliable circulating water washing exhaust gas treatment system includes a host computer, multiple PLC control cabinets and multiple exhaust gas treatment devices; the host computer is connected to the PLC control cabinet, and the PLC control cabinet is connected to the exhaust gas processing device connection;

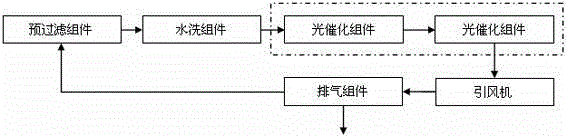

[0025] Such as figure 2 As shown, the exhaust gas treatment device includes a pre-filter assembly, a water washing assembly, an induced fan, and an exhaust assembly; the pre-filter assembly, the water washing assembly, the induced fan, and the exhaust assembly are connected in sequence through pipelines, and the exhaust air The assembly includes two outlets, one of which is used to discharge gas, and the other outlet is connected to the pre-filter assembly; an air replenishment valve is arranged between the pre-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com