Automobile body color paint film thickness control method and protection film covering tool

A technology of paint film thickness and control method, which is applied to the device, spray device, coating and other directions of coating liquid on the surface, can solve the problem of color difference of the finished car body, achieve short time consumption, ensure accuracy and save test time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

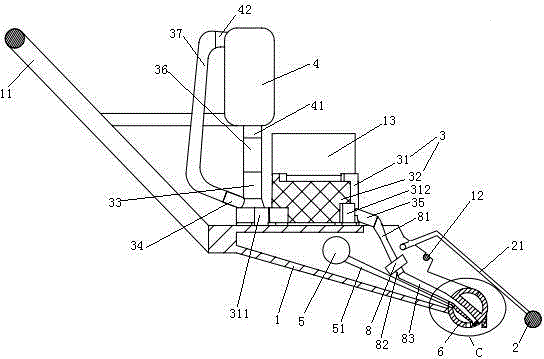

Image

Examples

Embodiment 1

[0034] Embodiment 1, a method for controlling the paint film thickness of a car body color paint, first obtain the color paint spraying flow rate of a new batch of color paint through the following steps:

[0035] The first step is to paste the tin plate at the detection point of the corresponding color paint film thickness of the car body in the good product;

[0036] The second step is to cover the surface of the vehicle body with a protective film in the good product; the protective film is a plastic film.

[0037] The third step is to cut off the plastic protective film on the part of the good product that is coated with the tin plate;

[0038] The fourth step is to make the good intermediate-coated car body enter the painting line and spray the new batch of colored paint onto the tinplate plate according to the preset spraying flow rate of the colored paint;

[0039] The fifth step, tearing off the protective film on the intermediate-coated car body of the good product; ...

Embodiment 2

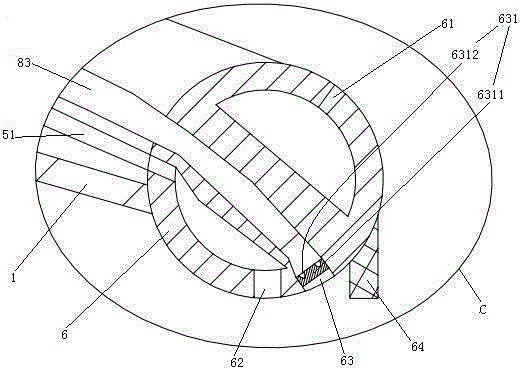

[0064] Embodiment two, see Figure 6 , the difference with Embodiment 1 is:

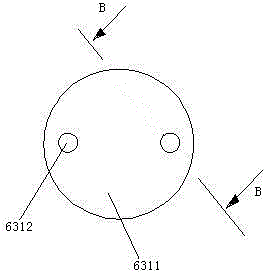

[0065] The water valve 8 includes a valve body 88 , a valve core 84 , a valve closing spring 85 and a spring support frame 86 . The valve body 83 is provided with a liquid flow channel 87 . The liquid flow channel 87 includes a conical section 871 and a cylindrical section 872 . The conical section 871 and the cylindrical section 872 are coaxial. The small-diameter end of the tapered section 871 is connected with the inlet 81 of the water valve. One end of the cylindrical section 872 is butted with the large-diameter end of the conical section 871 , and the other end penetrates to the outer surface of the valve body 88 to form the water valve outlet 82 . The spool 84 is located in the tapered section 871 . The spool 84 is tapered. The taper of the spool 84 is the same as that of the tapered section 871 . The spring support frame 86 is threadedly connected in the outlet 82 of the water valve. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com