Fluidized bed sorting experimental machine for arranging semi-automatic lifting device based on secondary bed layer

A secondary bed, fluidized bed technology, used in the separation of solids from solids by gas flow, solid separation, chemical instruments and methods, etc. Personnel physical and mental health and other issues, to achieve uniform and stable bed density, improve the accuracy of experimental results, and reduce the effect of human factor interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

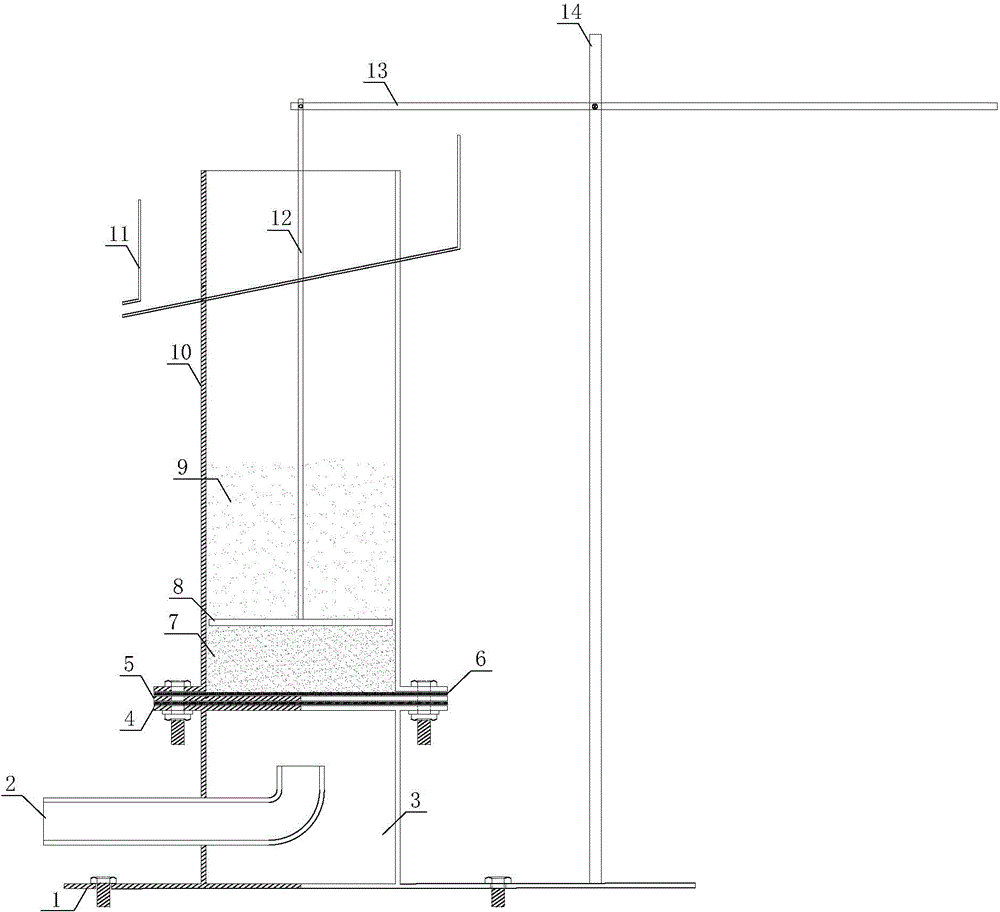

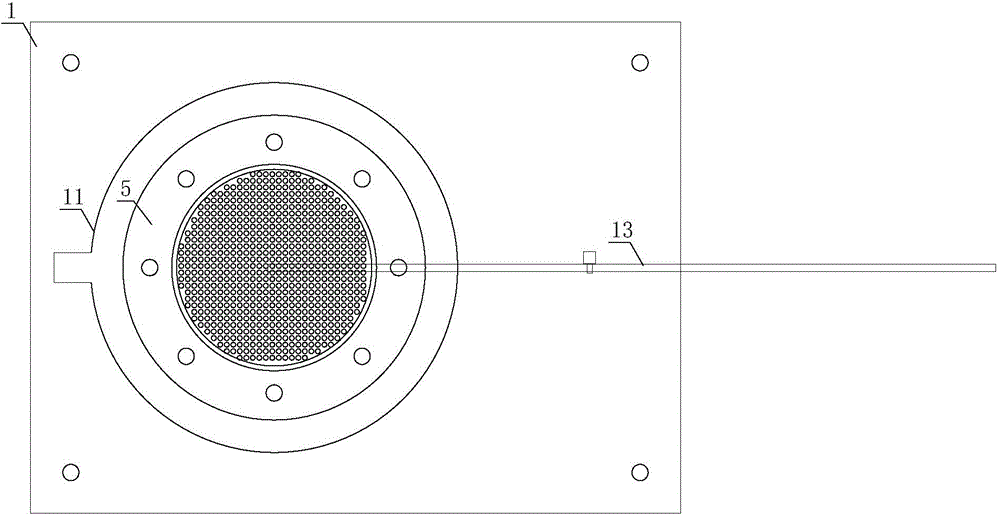

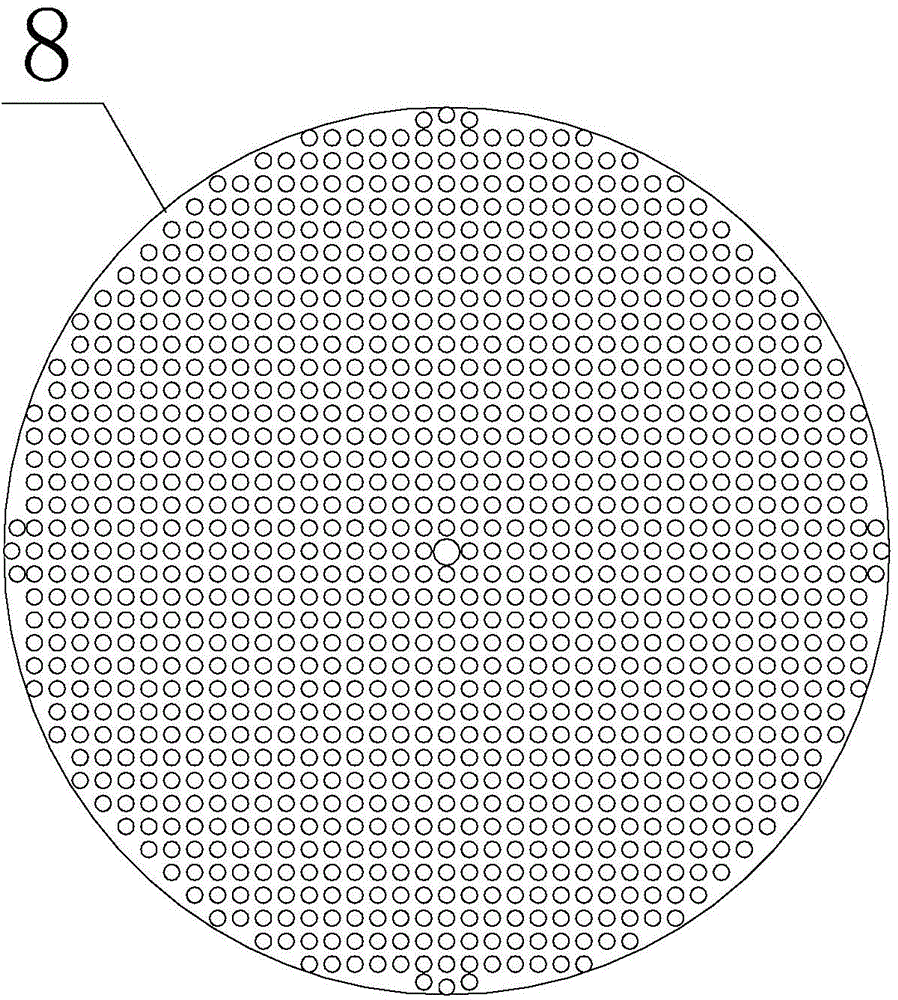

[0011] like figure 1 figure 2 As shown, the fluidized bed sorting test machine based on the secondary bed of the present invention with a semi-automatic material lifting device is mainly composed of a base 1, an air inlet pipe 2, an air distribution chamber 3, a first layer of air distribution plate 4, and a second layer Air distribution plate 5, filter cloth 6, weighted medium layer under the plate 7, secondary air distribution plate 8, weighted medium layer 9 on the plate, fluidized bed body 10, material receiving tray 11, vertical lifting rod 12 in the fluidized bed, The horizontal lever 13 and the outer vertical pole 14 of the fluidized bed constitute. The air distribution chamber 3 and the vertical rod 14 outside the fluidized bed are arranged on the base 1, and the base 1 is surrounded by a plurality of screw holes which can be fixed on the test be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com