Processing and polishing device for steel ball production

A steel ball and driving device technology, applied in metal processing equipment, grinding machines, manufacturing tools, etc., can solve the problems of inability to discharge powder in time, increase labor procedures, and small grinding area, and achieve uniform grinding, good grinding effect, The effect of large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

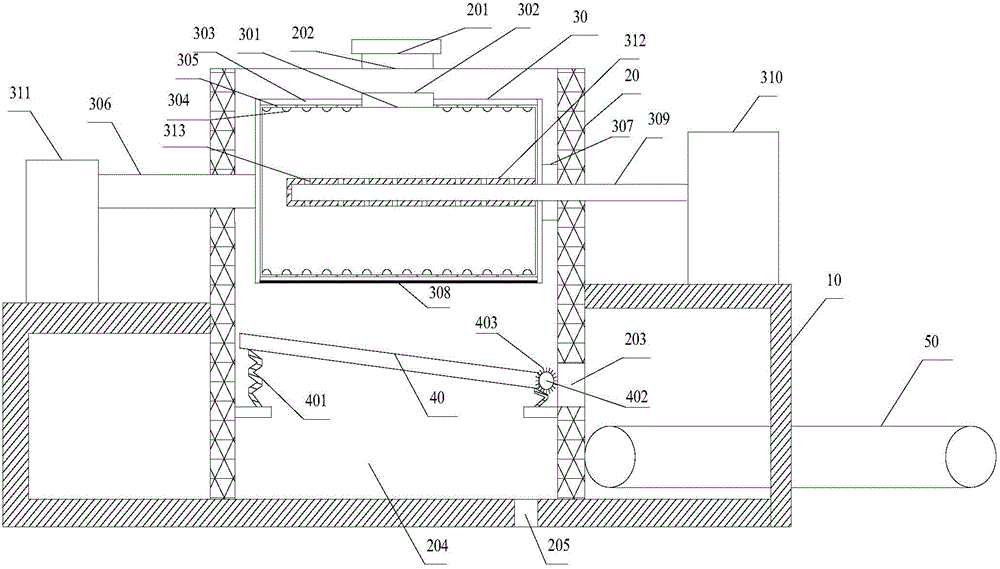

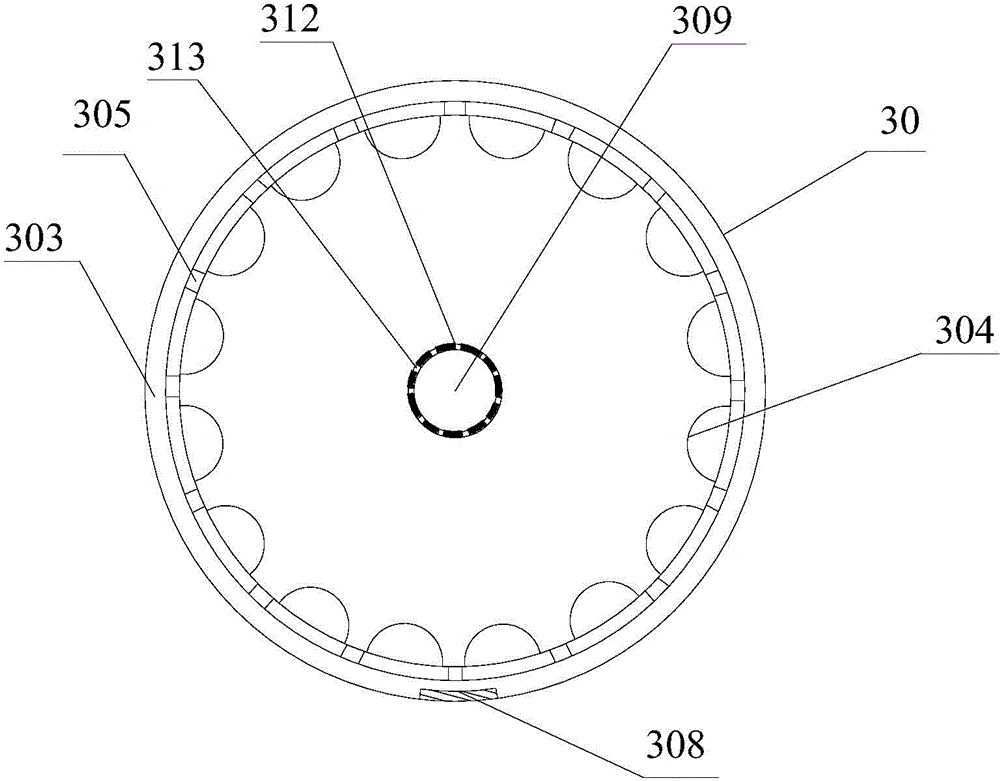

[0023] like figure 1 shown, figure 1 It is a schematic structural diagram of a steel ball production, processing and grinding device proposed by the present invention; figure 2 It is a cross-sectional view of the inner cylinder of a steel ball production, processing and grinding device proposed by the present invention.

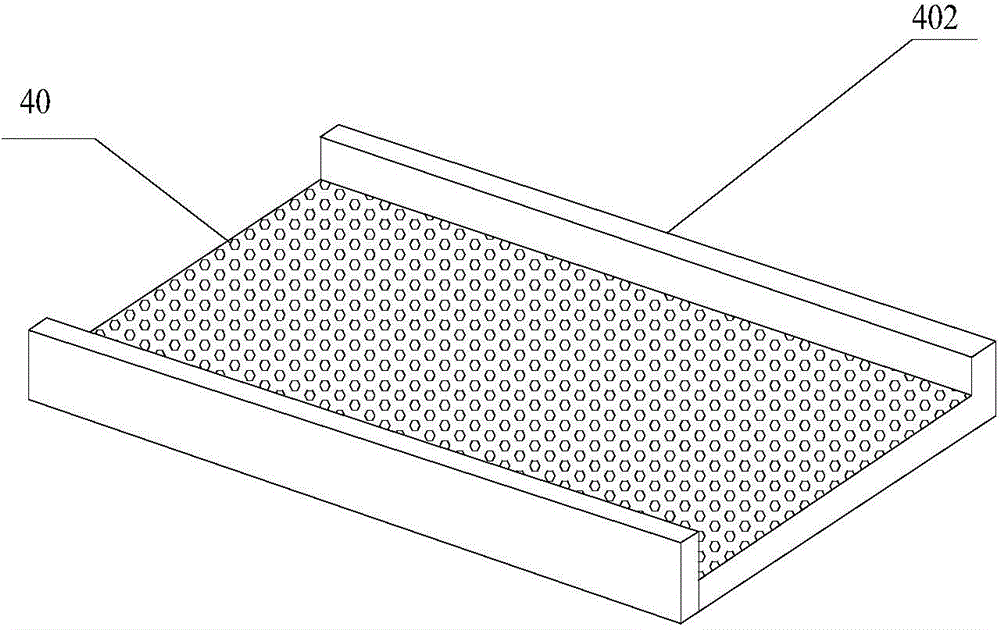

[0024] refer to figure 1 , figure 2 , image 3 , The present invention proposes a steel ball production, processing and grinding device, including a bracket 10, an outer box 20, an inner cylinder 30, a sieve plate 40, an air duct 309 and a discharge conveyor belt 50.

[0025] The outer box body 20 is installed on the bracket 10 , the upper end of the outer box body 20 is provided with a feeding port 201 , and the feeding port 202 is provided with a feeding door 201 .

[0026] The inner cylinder body 30 is arranged in the outer box body 20, the inner cylinder body 30 is provided with a material inlet and outlet port 301 at a position corresponding to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com